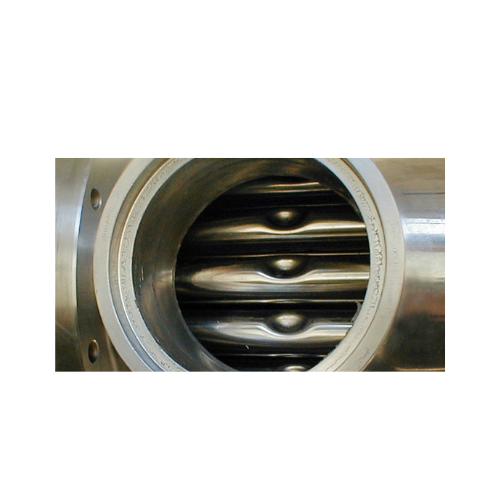

Tube-in-shell heat exchanger for low viscosity products

Enhance your beverage and food processing efficiency with a cutting-edge heat exchanger, designed to maximize heat transfer for liquid products, ensuring optimal pasteurization and sterilization. Perfect for operations seeking consistent thermal processing outcomes while maintaining product integrity.

Heats, Cools, and Sterilizes Liquid Products

The Sterideal® TS Tube-in-Shell Heat Exchanger from JBT is engineered for precision in the thermal processing of liquid products. This system is designed to maximize heat transfer efficiency with multiple small-diameter tubes within a larger shell, making it ideal for applications in coffee, tea, dairy, and fruit processing. It efficiently handles heating, cooling, pasteurization, and aseptic processing, ensuring product safety and quality. Compatible with various construction materials, including 316L stainless steel and special alloys, it withstands corrosive environments and high pressures. The exchanger offers customizable tube diameters, catering to specific throughput and thermal cycle requirements. Maintenance is streamlined via a Clean-in-Place (CIP) system, ensuring operational continuity. This equipment integrates seamlessly into existing production lines, providing reliable support for continuous liquid processing operations.

Benefits

- Enhances energy efficiency by optimizing heat transfer, reducing operating costs.

- Supports a wide range of liquids, from delicate juices to viscous pastes.

- Customizable design allows for precise adaptation to your processing needs.

- Easy integration with existing systems, minimizing installation disruptions.

- CIP capability simplifies cleaning, ensuring hygiene and reducing downtime.

- Applications

- Beverages, Tomato processing, Dairy alternatives, Coffee, Juices, Tea, Vegetable processing, Dairy, Fruit

- End products

- Apple juice, Orange juice, Oat milk, Almond milk, Black tea concentrate, Cold brew coffee, Vegetable soup, Tomato paste, Diced tomatoes, Fruit puree

- Steps before

- Aseptic Preparation, Fruit, Vegetable Processing, Dairy Processing, Juice Formulation

- Steps after

- Aseptic Packaging, Sterilization, Clean-in-Place, Dairy Product Packaging

- Input ingredients

- low viscosity products, hot water, cold water, glycol

- Output ingredients

- processed products

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Construction materials

- 316L to special alloys

- Heat transfer medium

- Hot water, cold water, glycol

- Tube diameter

- Varies based on design specifications

- Design type

- Tube-in-Shell

- Working mechanism

- Tube-in-shell

- Heat transfer medium

- Hot water / Cold water / Glycol

- Capability

- Low viscosity products

- Construction materials

- 316L to special alloys

- Tube diameter options

- Various depending on design specifications

- Material Types

- 316L, special alloys

- Tube Diameter

- Various (according to design specifications)

- Shell Diameter

- Large diameter

- Construction Material

- 316L to Special Alloys