Cup forming, filling, and sealing solution

Optimize your cup production with a compact solution designed for precise forming, filling, and sealing. Ideal for handling a variety of liquid to pasty products, this machine ensures minimal product loss and efficient integration into your existing line.

Forms, Fills, Seals, and Labels Cups

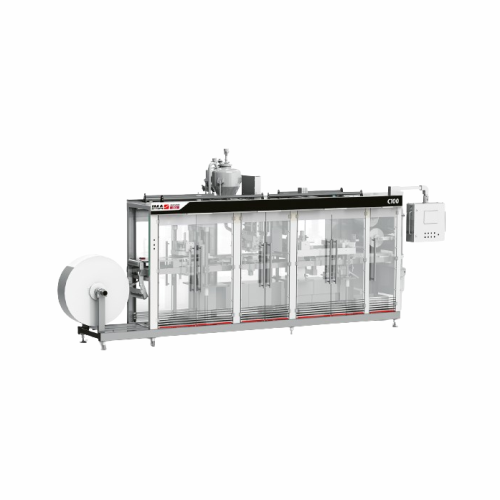

The C100 from IMA Group is a compact, modular machine that is ideal for food and dairy producers seeking efficient cup forming, filling, sealing, and labeling. Designed for versatility, it accommodates a variety of liquid-to-pasty products such as yogurt, fruit juices, and processed cheese. The C100’s servo-driven dosing pistons ensure maximum accuracy, minimizing product loss and enhancing productivity. It operates with a throughput of up to 7,000 cups per hour, making it suitable for low-output production lines. Its minimal footprint and intuitive HMI reduce operational and maintenance costs. The machine handles pre-formed and thermoformed cups, offering customized solutions to match specific design and labeling requirements. With options for ultra-clean hygiene specifications and adaptable configurations, the C100 integrates smoothly into diverse manufacturing environments, ensuring compliance with industry standards.

Benefits

- Enhances production efficiency with precise, servo-driven dosing for minimal product loss.

- Lowers operational and maintenance costs with a compact footprint and intuitive HMI.

- Supports a wide range of product types, from liquids to pasty foods, increasing versatility.

- Customizable configurations meet specific design and labeling needs for product differentiation.

- Maintains high hygiene standards, offering options up to ultra-clean specifications.

- Applications

- Liquid foods, Pasty foods, Cheese, Desserts, Yogurt, Purees, Fruit juice, Dairy products

- End products

- Mango smoothie, Vanilla custard, Blueberry yogurt, Apple sauce, Greek yogurt, Cream cheese, Chocolate pudding, Tomato paste, Strawberry fruit puree, Processed cheese slices

- Steps before

- Purification, Homogenization, Mixing, Emulsification

- Steps after

- Packing, Labelling, Sterilization, Quality Control

- Input ingredients

- liquid-to-pasty products, yogurt, fruit juice, white cheese, desserts, purees, thermoformed cups, pre-formed cups, packaging materials, PS and multilayers, PS/PE, PS/EVOH, PET

- Output ingredients

- sealed cups, filled yogurt cups, filled fruit juice cups, filled white cheese cups, filled desserts, filled purees, thermoformed and labelled cups, packaged liquid-to-pasty food products

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Output Capacity

- Up to 7, 000 cups per hour

- Footprint

- Small/Compact

- Dosing System

- Servo driven dosing pistons

- Feasible Cup Shapes

- Large variety

- Machine Type

- Form, Fill, and Seal

- Material Width

- 300 mm

- Draw Off Length

- Max. 100 mm

- Usable Width

- 286 mm

- Forming Depth

- Max. 100 mm

- Packing Materials

- PS and multilayers, PS/PE, PS/EVOH, PET

- Standard Equipment Components

- ELAU, FESTO, Magelis 10”

- Hygiene Class

- Clean

- Options for Hygiene Class

- Ultra-clean

- Cutting Tool

- Waste less punch for packs

- Exit Conveyor

- Belt

- Fillers

- Rotary valve filler, up to 2 fillers

- Label Reel

- N/A

- Sealing Compatibility

- Liquid-to-pasty products, with or without particulates

- Heating Station

- 6 pitches

- Working Mechanism

- Form, fill, and seal machine

- Integrated Steps

- Forming, Filling, Sealing

- Output

- Up to 7, 000 cups per hour

- Modular Structure

- Yes

- Automation Level

- Servo-driven dosing pistons

- Product Variety

- Liquid-to-pasty products

- Product Design Flexibility

- Various cup shapes and designs

- Density/particle size

- 50–1000 µm

- Machine footprint

- Compact

- Discharge method

- Exit conveyor with belt

- Control panel type

- Simple, intuitive HMI Magelis 10”

- Cup Shapes

- Large variety of shapes and designs

- Cup material width

- 300 mm

- Draw off length

- max. 100 mm

- Usable width

- 286 mm

- Forming depth

- max. 100 mm

- Bottom web reel Ø

- 1.000 mm

- Lid web reel Ø

- 300 mm

- Label reel

- N/A

- Control panel type

- HMI Magelis 10”

- Modular structure

- Yes

- Fillers

- Rotary valve filler, 2 fillers possible in 1×4 configuration