High-performance palletizer for cans, Pet, and glass containers

Elevate your palletizing efficiency with cutting-edge robotics designed to handle a diverse range of containers, ensuring seamless integration and flexibility for future production needs.

Palletizes and Groups Containers Efficiently

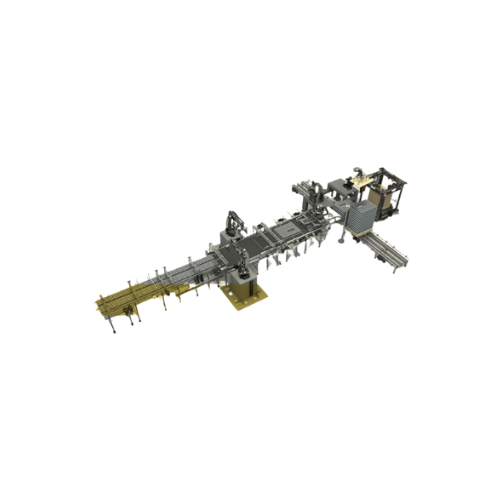

The Innopal PLR from KHS Group is a high-performance robot palletizer engineered for seamless integration into beverage and food production lines, accommodating containers made of PET, glass, and cans. Utilizing state-of-the-art robotics, it ensures precise palletizing, grouping, and layer pad handling across various formats, offering fully automatic format changeovers that enhance operational efficiency. Capable of processing up to 625 layers per hour, the system is ideal for products ranging from carbonated soft drinks to cosmetic containers. Its energy-efficient design enables energy recovery during deceleration, reducing operational costs. The low-level container infeed improves accessibility and safety, while the system’s flexible platform allows for customization and adaptation to evolving production requirements. Additionally, the Innopal PLR maintains a high resale value, offering long-term investment benefits and minimal maintenance needs due to its robust robotic technology.

Benefits

- Enhances operational efficiency with fully automatic format changeovers.

- Increases safety and accessibility with a low-level container infeed.

- Offers long-term investment value with high resale potential.

- Reduces energy costs through energy recovery during robotic decelerations.

- Minimizes maintenance expenses with state-of-the-art robotics.

- Applications

- Food, Pet bottles, Wine, Milk, Nonfood, Containers, Iced tea, Spirits, Still water, Glass containers, Cans, Juice, Soft drinks, Beer, Sparkling wine

- End products

- Pilsner, Chardonnay wine, Lager beer, Green iced tea, Orange juice, Frozen food packaging, Prosecco, Juice cans, Beer glasses, Carbonated pet water bottles, Artesian water bottles, Carbonated soft drinks, Cosmetic containers, Flavored milk, Vodka

- Steps before

- Material Handling, Container Filling, Quality Control, Pre-Inspection

- Steps after

- Packing, Labeling, Secondary Packaging, Distribution

- Input ingredients

- cans, PET bottles, glass containers

- Output ingredients

- palletized layers, grouped containers, layer pads

- Market info

- KHS is known for manufacturing innovative filling and packaging systems for the beverage, food, and non-food industries, renowned for their engineering expertise, high-quality standards, and sustainable solutions in ensuring efficient production processes.

- Speed

- Up to 625 layers per hour

- Capacity

- Processes all standard formats

- Container Compatibility

- Cans, PET, glass

- Automation

- Fully automatic format changeovers

- Energy Efficiency

- Energy recovery during deceleration

- Low-level Pack Infeed

- Yes

- Flexibility

- Adapts to changing requirements

- Automation Level

- Fully automatic with robotics

- Changeover Time

- Automatic format changeovers

- Batch vs. Continuous Operation

- Continuous

- Cleaning Method

- Low-level accessibility for easier maintenance

- Energy Efficiency

- Energy recovery during all decelerations

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container type

- PET / Glass / Cans

- Container size

- Standard formats

- Packaging type

- Film / Paper / Cardboard

- Palletizing type

- Robotic

- Pallet infeed level

- Low-level

- Energy recovery

- During deceleration

- Feed method

- Low-level infeed

- Robot integration

- Fully robotic

- Layer capacity

- Up to 625 layers per hour

- Container compatibility

- Cans, PET, Glass

- Customization options

- Modules for various container sizes and types

- Integration possibilities

- Seamlessly integrates into existing lines

- Layout configuration

- Tailored to exact requirements

- Platform system

- Modular

- Format changeover

- Fully automatic