Industrial high-pressure homogenizer

Achieve precise homogenization with superior flow rates and efficiency, ensuring optimal consistency and stability in high-demand processing environments.

Homogenizes and Emulsifies Viscous Liquid Products

The Ariete Homogenizer 5400 from GEA is a high-pressure industrial homogenizer designed to efficiently homogenize and emulsify viscous liquid products across various industries, including dairy, beverage, pharmaceutical, and chemical sectors. This equipment stands out for its versatility, handling capacities of up to 80,000 liters per hour at 120 bar, making it ideal for processing products such as milk, yogurt, fruit juices, carbonated soft drinks, and pharmaceutical emulsions.

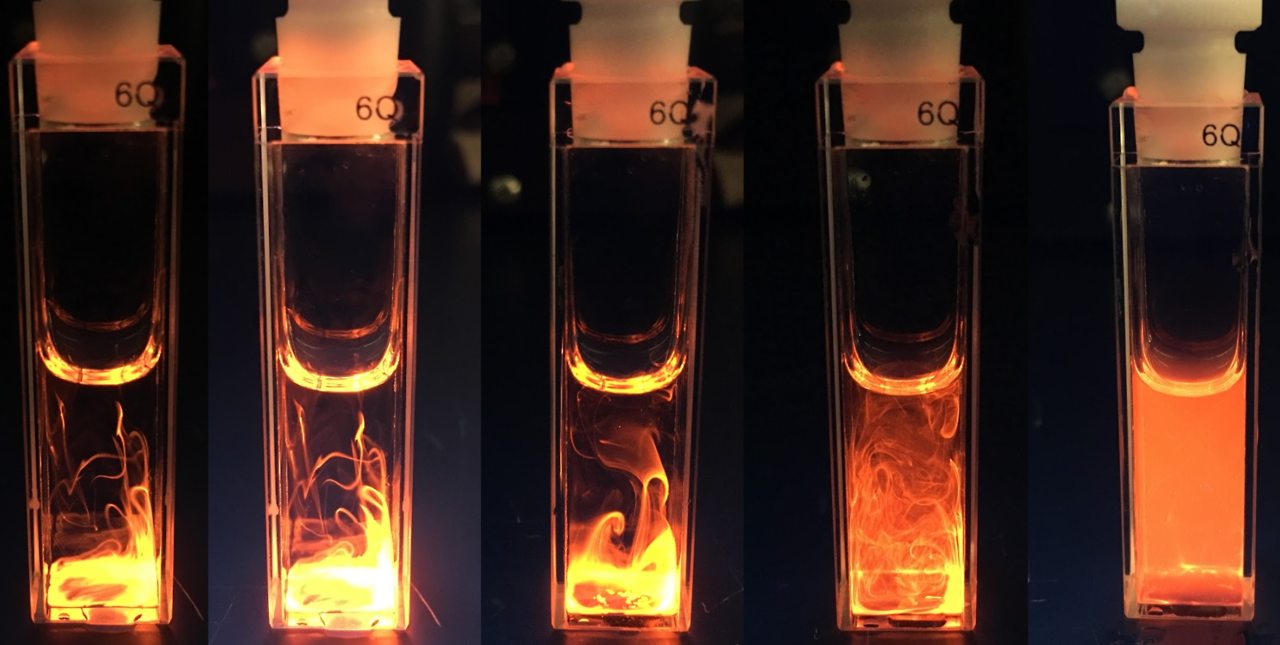

The unit utilizes a high-pressure multi-piston pump to ensure consistent and uniform product textures, integrating smoothly into continuous high-speed operations. Equipped with options like the NiSoPURE, NanoVALVE, and OPS, it enhances energy efficiency, offering savings on production costs by minimizing power, water, and oil usage. Constructed for reliability, its strengthened design minimizes vibrations and pulsations, suitable for even challenging applications like fibrous juices or dense dairy by-products.

In terms of automation, the Ariete Homogenizer 5400 is PLC-controlled with optional remote monitoring, allowing seamless integration into modern production lines. Crafted from durable materials, it meets stringent industrial standards, ensuring compliance with GMP and FDA requirements. Cleaning is swift and contamination-free, thanks to its CIP compatibility and design features that prevent water stagnation. Customization is supported with the choice of motor sizes, ensuring optimal performance tailored to specific production needs.

Benefits

- Increases production efficiency with high flow rates up to 80,000 liters per hour.

- Lowers operational costs through 7% higher energy efficiency in its class.

- Ensures product consistency and quality across dairy, beverage, and pharmaceutical outputs.

- Minimizes maintenance time with user-friendly design and easy access for service.

- Enhances safety and compliance with aseptic design suitable for GMP and FDA standards.

- Applications

- Chemicals, Beverages, Fibrous juices, Viscous products, Dairy by-products, Dairy, Probiotics, Pharmaceuticals

- End products

- Milk, Custard, Probiotic drinks, Almond milk, Cough syrups, Soy milk, Pharmaceutical emulsions, Chemical suspensions, Sauces, Condensed milk, Yogurt, Carbonated soft drinks, Fruit juices, Whey protein

- Steps before

- Purification, Mixing, Pre-heating, Grinding

- Steps after

- Stabilization, Cooling, Packing, Sterilization, Quality Control

- Input ingredients

- dairy products, beverages, pharmaceutical ingredients, chemical materials, viscous products, fibrous juices, dairy by-products, probiotics

- Output ingredients

- homogenized dairy products, homogenized beverages, homogenized pharmaceuticals, homogenized chemicals, viscosity improved products, stable emulsions

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Capacity

- 80, 000 l/h @ 120 bar

- Motor Power

- 315 kW

- Efficiency

- 7% higher efficiency in its class

- Flow rate

- 80, 000 L/h @ 120 bar

- Automation level

- PLC / SCADA

- CIP/SIP

- Easy cleaning / No water stagnation

- Flexibility

- Viscous, fibrous products

- Energy efficiency

- High efficiency / 7% higher in class

- Versatility

- Dairy, beverage, pharmaceutical, chemical

- Safety measures

- Reduced pulsation, stable design

- Changeover time

- Minimized due to design

- Product type

- Dairy, beverage, pharmaceutical, chemical

- Application versatility

- Wide market demands

- Discharge method

- Straight pipes for inlet and outlet connection to manifold

- Control panel type

- User-friendly/accessibility

- Footprint

- Designed for high flow-rate (80, 000 l/h@120 bar)

- Motor power options

- 315 kW

- Integration features

- GEA high efficiency options (NiSoPURE, NanoVALVE, OPS)

- Aseptic capabilities

- Pharmaceutical grade hygiene and safety