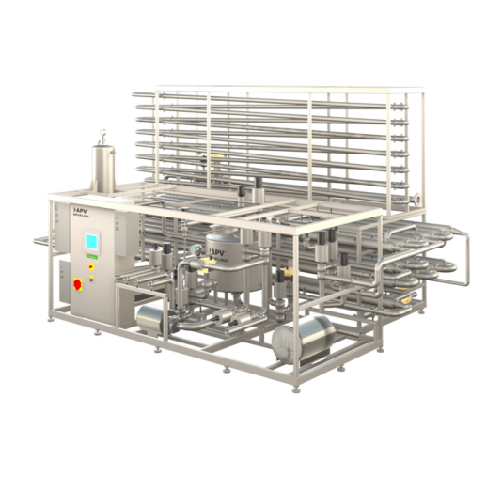

Tubular juice pasteurizer

Ensure optimal safety and quality of liquid products with precise temperature control and high heat recovery, seamlessly integrating into your existing processing line.

Pasteurizes and Integrates with Production Lines

The Tubular Juice Pasteurizer System by SPX FLOW offers a modular and flexible solution for your beverage and food processing needs. It excels in efficiently pasteurizing liquids like orange juice, apple juice, soy milk, and drinking yogurt, ensuring quality and safety. Featuring automated control systems, it leverages precise temperature control and flow diversion to optimize pasteurization while achieving high heat recovery for reduced energy costs. With a processing capacity ranging from 3,000 to 35,000 liters per hour, it integrates seamlessly into existing production lines, offering both continuous operation and compact, skid-mounted design for space-efficient installation. The system is constructed from high-grade materials, ensuring durability and compliance with industry standards, and includes factory-tested components for reliable performance. Maintenance is streamlined with simple procedures, minimizing downtime and promoting a high return on investment over its service life.

Benefits

- Increases production efficiency with rapid installation and commissioning.

- Minimizes operational costs through high heat recovery.

- Ensures product quality with precise temperature control and traceability.

- Reduces labor demands with seamless integration into existing systems.

- Optimizes space usage with its compact, skid-mounted design.

- Applications

- Beverages, Plant-based drinks, Milk, Aseptic products, Dairy processing, Yogurt, Baby food, Fruit juice

- End products

- Smoothies, Infant fruit puree, Aseptic packaged juice, Uht milk, Drinking yogurt, Baby formula, Apple juice, Orange juice, Almond milk, Soy milk

- Steps before

- Juice Extraction, Juice Filtration, Juice Homogenization

- Steps after

- Cooling, Filling, Capping, Labeling, Packing

- Input ingredients

- juice

- Output ingredients

- pasteurized juice

- Market info

- SPX Flow is renowned for its expertise in manufacturing industrial ETO equipment, specializing in fluid handling and processing solutions. They are recognized for innovation, reliability, and providing efficient solutions across diverse industries, including food, beverage, and industrial markets.

- Automation

- Automatic control of pasteurization temperature

- Capacity

- 792 to 9, 246 g/h (3, 000 to 35, 000 l/h)

- Flow Control

- Automatic flow diversion

- Heat Recovery

- High heat recovery

- Footprint

- Skid-mounted and small footprint

- Installation

- Pre-assembled and factory-tested

- Flexibility

- Modular system

- Pasteurization temperature control

- Automatic

- Flow diversion control

- Automatic

- Traceability

- Continuous recording

- Heat recovery

- High

- Operation type

- Skid-mounted

- Flexibility

- Modular system

- Installation

- Pre-assembled and factory-tested

- Maintenance

- Simple low-cost

- Integration

- Existing control system

- Footprint

- Small

- Cleanability

- Designed for CIP

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Compact footprint

- Skid-mounted and small footprint

- Control panel type

- Automatic control

- Modular system

- Yes

- Control panel type

- Automatic control

- Integration possibilities

- Integration with existing control system

- Modular system

- Complete flexibility

- Skid-mounted

- Yes

- Footprint

- Small