Intelligent pre-dosing system for fruit juices

Optimize your beverage production by minimizing fruit piece damage and ensuring precise dosing in mixed drinks, enhancing both quality and operational efficiency.

Processes and Integrates Fruit Components in Beverages

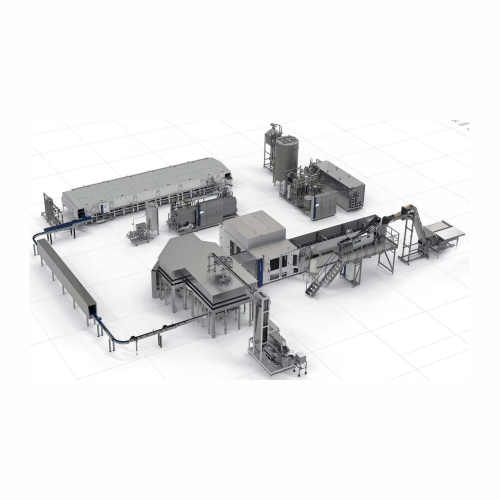

The Krones FlexiFruit system offers an innovative solution for beverage producers looking to seamlessly integrate fruit pieces into liquid products without compromising quality. This intelligent, self-adjusting dosing system operates using a twin-flow method that separately processes fruit and juice to ensure minimal damage to sensitive components. The process begins with pre-dosing fruit pieces independently of the aseptic or hot filling operation. Fruit particles are gently heated in tubular heat exchangers and carefully mixed with the main juice flow, which is treated with plate heat exchangers to reduce oxidation.

This system is particularly suited for applications such as premium orange juice with pulp, aloe vera drinks with fruit bits, or smoothies with fruit chunks across industries including food and beverage, dairy, and juice production. With capacities designed for high-speed, continuous processing lines, the Krones FlexiFruit maintains precise dosing, preventing overdosing and ensuring cost efficiency.

Automation integrates seamlessly within production lines, aided by uniform materials and a consistent software solution, confirming easy maintenance and minimal downtime. Energy efficiency is bolstered by high-recovery heat exchangers, reducing overall operating costs. For industries focused on processing sensitive or varied fruit components into liquid products, the Krones FlexiFruit represents a comprehensive, energy-efficient solution engineered for quality and performance.

Benefits

- Preserves fruit integrity by reducing damage during processing.

- Enhances product consistency with precise fruit dosing capabilities.

- Lowers operational costs through energy-efficient heat exchangers.

- Seamlessly integrates with existing high-speed production lines.

- Minimizes resource waste and overdosing in beverage production.

- Applications

- Juices, Beverages with fruit components, Mixed milk beverages

- End products

- Berry-infused water with fruit pieces, Aloe vera drink with fruit bits, Premium orange juice with pulp, Strawberry banana smoothie with pieces, Mango lassi with fruit chunks, Coconut milk drink with fruit cubes, Pineapple juice with diced fruit

- Steps before

- Juice extraction, Fruit preparation, Deaeration, Heating, Flash pasteurization

- Steps after

- Cooling, Packing, Labeling, Quality inspection, Storage

- Input ingredients

- fruit components, juice, food pieces, sugar, powder, syrup, concentrate

- Output ingredients

- beverages with fruit components, premium fruit juices, mixed milk beverages

- Market info

- Krones is renowned for its expertise in manufacturing beverage and liquid food processing and packaging equipment, offering comprehensive solutions that include filling, packaging technology, and processing systems, and is reputed for innovation and quality in the industry.

- Dosing type

- Manual / Auto dosing

- Fruit piece size

- 10x10x10 mm

- Dosing precision

- High-precision

- Heating method

- Plate heat exchanger / Tubular heat exchanger

- Automation

- Self-adjusting pre-dosing system

- Working mechanism

- Twin-flow method

- Integrated steps

- Separate processing of fruit and juice

- CIP/SIP

- CIP compliant

- Batch vs. continuous operation

- Continuous (inline) operation

- Automation level

- Self-adjusting via Modulfill filler

- Cleaning method

- Automated CIP compatible

- High-precision dosing

- Predefined quantities maintained

- Energy efficiency

- High energy recovery heat exchangers

- Abrasion resistance

- High

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- 0.5–2.5 g/cm³

- Footprint

- Compact design for minimal space

- Fruit piece size

- 10 x 10 x 10 mm

- Pre-dosing system

- Intelligent and self-adjusting

- Heat exchangers type

- Plate and tubular

- Container types supported

- PET / Glass / Others

- Control system

- Integrated with Modulfill filler

- Cooling System

- Cooling tunnel for hot filling

- Control panel type

- Self-adjusting pre-dosing system

- Integration possibilities

- Modular integration with Modulfill filler

- Fruit piece size adjustment

- Up to 10 x 10 x 10 millimetres

- Processing method

- Twin-flow method