Semi-automatic stands blender for facade paints

Optimize your paint production with a versatile stirring system designed for precise color mixing and consistent viscosity control, ensuring high-quality facade paints and coatings.

Mixes and Colors Viscous Liquids and Slurries

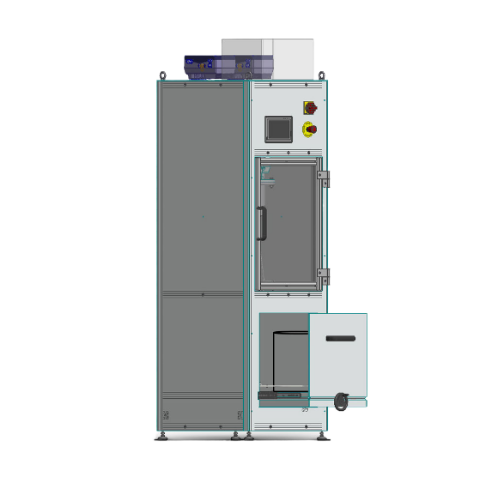

The VISCO JET® VJ411 from VISCO JET Rührsysteme is a semi-automatic mixer specifically engineered for the precise mixing and coloring of viscous liquids and slurries, such as facade paints and decorative plasters. This mixer incorporates a digital control unit with an integrated touch-screen, allowing for programmable stirring sequences that enhance process reproducibility. Featuring a VISCO JET®Pyramide stirring tool and a quick-change coupling system, it facilitates easy adaptation to various mixing tasks. Suitable for processing volumes between 5 and 30 liters, the VJ411 is optimized for efficient operation with a 1.1 kW motor, ensuring effective mixing of substances up to 9,000 mPas viscosity. Construction from stainless steel and aluminum profiles guarantees durability and corrosion resistance, ideal for diverse industries, including paints, cosmetics, and pharmaceuticals. Its manual container clamping mechanism and safety enclosure provide secure operation, while compliance with EU safety and electromagnetic standards ensures reliable integration into production lines. Maintenance is streamlined with user-friendly access to all necessary components, supporting continuous, efficient operations.

Benefits

- Ensures uniform consistency and pigmentation, essential for high-quality paint and coating production.

- Minimizes setup time with a quick-change coupling system for different mixing tasks.

- Lowers operational risk with comprehensive safety encloses and manual clamping.

- Enhances production efficiency by automating stirring processes through digital, programmable controls.

- Reduces maintenance needs with durable stainless steel construction resistant to corrosion.

- Applications

- Chemicals, Ceramics, Facade paints, Dairy products, Coatings, Plasters, Cosmetics, Food and beverages, Sweets, Petrochemicals, Soaps, Mining, Paints, Paper manufacturing, Pharmaceuticals

- End products

- Chocolate truffles, Mineral slurries, Skincare creams, Ceramic glazes, Detergents, Pharmaceutical creams, Interior wall paints, Paper pulp slurry, Yogurt, Decorative plasters, Soap bars, Industrial oils, Exterior coatings, Fruit juices

- Steps before

- Preparation of paint or coatings, Selection and preparation of containers, Loading containers onto the machine

- Steps after

- Toning or coloring finishes, Quality control and testing, Packaging of mixed products

- Input ingredients

- Fassadenfarben, Putze, Farben, Tönungen, Behälter 5 bis 30 Liter

- Output ingredients

- aufgerührte Fassadenfarben, aufgerührte Putze, getönte Farben, getönte Tönungen

- Market info

- Visco Jet Ruhrsysteme is known for manufacturing advanced mixing and stirring equipment, particularly industrial agitators, which are engineered-to-order for various industries. Their expertise lies in efficient and tailored mixing solutions with a strong reputation for innovation and quality.

- Automation

- Touch-screen digital control

- Capacity

- 5–30 L

- Hubhöhe (Lifting height)

- 400 mm

- Antriebsleistung (Drive power)

- 1.1 kW

- Spannungsversorgung (Voltage supply)

- 400 V

- Material

- Aluminum profile and stainless steel

- Schnellwechselkupplung (Quick-change coupling)

- Yes

- Rezeptverwaltung (Recipe management)

- 10 programs

- Rühreinheit (Agitator unit)

- VISCO JET® PYRAMIDE

- Automation level

- Manual / Digital Touch-Screen

- Batch vs. continuous operation

- Batch

- Cleaning method

- Manual

- Energy efficiency

- 1.1 kW motor drive

- Changeover time

- Quick with Schnellwechselkupplung

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compatibility with high viscosity

- Up to 9, 000 mPas

- Surface finish compatibility

- Edelstahl (Stainless Steel) 1.4404/1.4571

- Container size

- 5–30 liters

- Container type

- Round / Oval

- Machine footprint

- 2.066 x 761 x 532 mm

- Hub height

- 400 mm

- Material of construction

- Aluminium and Stainless Steel

- Container compatibility

- 5 to 30 L

- Control panel type

- Touch-screen

- Discharge method

- Manual removal

- Safety features

- Sicherheitsumhausung

- Material

- Aluminiumprofil Bauweise, Edelstahl 1.4404/1.4571

- Control panel type

- Integrated Touch-Screen

- Rührorgane customization

- Schnellwechselkupplung for easy tool exchange

- Container size compatibility

- 5–30 Liters

- Customization for container type

- Round/Oval Containers