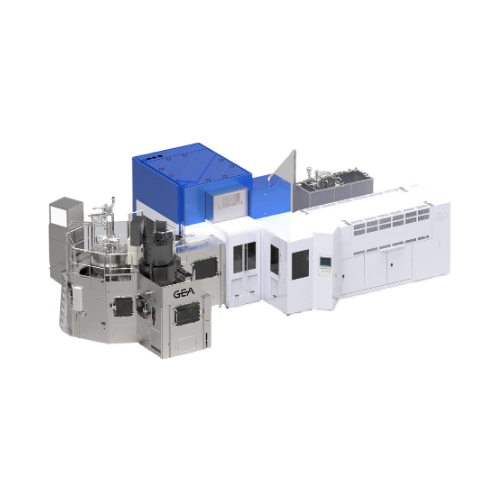

Decontamination blow fill system for beverages

Optimize your beverage production with a technology that integrates preform decontamination and blow-fill processes, enhancing shelf-life while ensuring complete sterilization without water usage. Ideal for makers of sensitive drinks seeking efficient, continuous high-speed operations.

Sterilizes, Blows, and Fills Sensitive Beverages

The GEA Decontamination Blow Fill System (DBF) integrates preform sterilization, blow molding, and aseptic filling into a cohesive operation to address the complexities of beverage processing. This system specializes in handling sensitive beverages, achieving shelf stability and extended shelf life for products ranging from carbonated soft drinks to nutraceutical drinks. Preform sterilization with Vapor Hydrogen Peroxide (VHP) ensures a completely dry, environmentally sustainable method, minimizing water consumption and enabling lightweight bottle designs.

The process involves precise preform heating and sterilization before blow molding with sterile air, optimizing high-speed production for complex bottle shapes. The DBF system’s aseptic filling accommodates extensive variability, managing various beverage consistencies, including those with pulp and fiber. Capable of high throughput and efficient changeovers, it meets dynamic production demands. The PLC-controlled system supports seamless integration into existing production lines, while its reduced footprint and minimized operator requirements enhance operational efficiency. Designed with high corrosion resistance and compliance with stringent hygiene standards, it supports CIP for easy cleaning, ensuring product safety and quality throughout production.

Benefits

- Optimizes energy use with dry sterilization, reducing water consumption.

- Ensures extended shelf life with reliable preform decontamination.

- Supports rapid product changeovers, enhancing productivity for diverse beverage lines.

- Minimizes operational costs by eliminating the need for bottle rinsing and air conveyors.

- Provides robust safety and hygiene compliance with integrated Smart Sensor technology.

- Applications

- Carbonated beverages, Beverages, Extended shelf life (esl) drinks, Sensitive beverages, Beverages with pulp, Beverages with fibers, Dairy alternatives, Nutraceutical drinks, Beverages with fruit pieces, Juice, Shelf stable drinks, Still beverages

- End products

- Extended shelf-life iced teas, Cold brew coffee beverages, Protein shakes, Almond milk, Functional beverages with added vitamins, Soy milk, Electrolyte sports drinks, Fruit juices with pulp, Energy drinks, Flavored waters, Vegetable juices with fibers, Lactose-free milk, Kefir-based drinks, Smoothies containing fruit pieces, Dairy-free yogurt drinks, Carbonated soft drinks, Kombucha

- Steps before

- Preform Production, Preform Heating

- Steps after

- Blowing, Aseptic Filling, Packaging

- Input ingredients

- preforms, Vapor Hydrogen Peroxide (VHP), sterile air

- Output ingredients

- sterilized preforms, blown bottles, still beverages, carbonated beverages, sensitive beverages, shelf stable products, extended shelf life (ESL) products, beverages with pulp, beverages with fibers, beverages with pieces of fruit, beverages with cereals

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Blowing air pressure

- Sterile air at high pressure

- Preform heating treatment

- Dedicated air flows for neck and body cooling

- Sterilization agent

- Vapor Hydrogen Peroxide (VHP)

- Automation

- Integrated blow-fill technology

- Sterilization process

- Single process with a single media

- Production Capacity

- High speed capacity production

- Decontamination process

- Dry sterilization

- Preform decontamination

- VHP dry technology

- Aseptic filling module

- Handles variability in SKUs

- Beverage type capacity

- Sensitive, still, carbonated, and with particles

- Closure sterilization

- VHP-based

- Capping module

- Designed for aseptic applications

- Working mechanism

- Preform decontamination and blow-fill integrated technology

- Integrated steps

- Sterilization, blowing, filling

- Batch vs. continuous operation

- Inline Continuous

- Changeover time

- Quick and easy format changeover

- Cleaning method

- Dry sterilization with VHP

- Energy efficiency

- Optimized to reduce chemical and material use

- Automation level

- High, with smart sensors

- Air incorporation control

- Sterile air for bottle blowing

- Chemical resistance

- Acids, VHP

- Cleanability

- Dry process

- Sterilization compatibility

- VHP

- Corrosive resistance

- Yes

- Sensitivity

- Sensitive to heat and contaminants

- Beverage type

- Still / Carbonated / With pulp

- Aseptic filling

- ESL or Shelf-stable

- Footprint

- Minimal due to elimination of air conveyors and bottle sterilization turrets

- Sterilization method

- Vapor Hydrogen Peroxide (VHP)

- Format changeover capability

- Rapid and user-friendly

- Blowing mold design

- Wide high-pressure blowing angle

- Container type flexibility

- Large volume to single serve containers

- Control Panel Type

- Touchscreen / HMI

- Integration Possibilities

- SCADA / PLC

- Filling Module Variability

- Large volume to single serve

- Cap Type

- Sport / Flat design

- Blowing Module Format Changeover

- Quick and easy