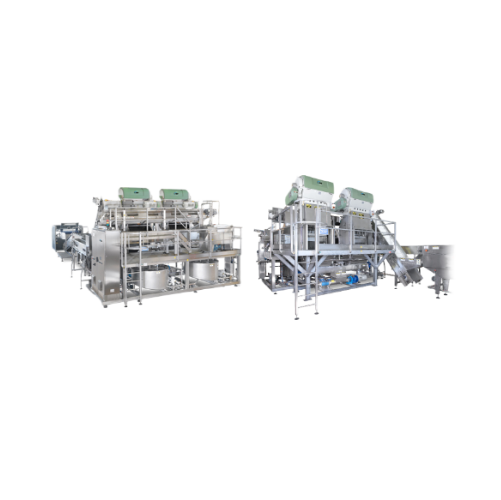

Citrus juice extraction system

Optimize your citrus juice processing with a compact, flexible system that efficiently extracts juice while delivering high-quality output.

Extracts and Processes Citrus Juice Efficiently

The READYGo™ JUICE FAMILY by JBT FoodTech offers compact, skid-mounted citrus juice extraction systems designed specifically for efficient processing of citrus fruits like oranges, lemons, and limes. Each system is adaptable, integrating smoothly into existing production lines with capacities ranging from 3 to 18 metric tons per hour, depending on configuration. Engineered for continuous operation, it optimizes space while ensuring high-quality juice extraction. The system is equipped with multiple extractor cup options for flexibility and a straightforward cleanup process via its integrated CIP (clean-in-place) system. Its design ensures seamless delivery of processed juice to either pasteurizers or storage facilities, catering to both short-life products and further processing needs. Constructed from durable materials to withstand rigorous processing environments, it also features PLC control for enhanced automation and remote management capabilities, making it an ideal choice for citrus processors and juice manufacturers aiming to increase efficiency while reducing footprint and operational costs.

Benefits

- Optimizes production efficiency with compact, skid-mounted design for tight spaces.

- Lowers operational costs through flexible extractor configurations tailored to varying capacities.

- Ensures consistent product quality with seamless integration to pasteurization and storage systems.

- Simplifies cleaning processes, minimizing downtime with an integrated clean-in-place system.

- Enhances operational flexibility with adaptable extractor cup options for diverse citrus processing needs.

- Applications

- Beverages, Citrus juice, Plant-based beverages, Fresh produce, Fruit processing, Juices

- End products

- Citrus juice blends, Lemon juice, Citrus concentrate, Sweet lime juice, Freshly-squeezed juice, Orange juice, Grapefruit juice, Plant-based citrus beverages, Tangerine juice, Lime juice

- Steps before

- Fruit Sorting, Fruit Washing, Presizing

- Steps after

- Juice Pasteurization, Juice Storage, Further Processing

- Input ingredients

- oranges, lemons, grapefruits, tangerines, limes, sweet limes, pre-sized fruit, bulk raw material

- Output ingredients

- finished juice, pasteurized juice, stored juice for further processing

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Capacity

- 3 m tons/h (SJE)

- Capacity

- 6 m tons/h (DJE)

- Capacity

- Multiple extractor configuration

- Fruit Type

- Oranges, lemons, grapefruits, tangerines, limes, sweet limes

- System Type

- Skid-mounted

- Automation

- Simple clean-up system in place

- Footprint

- Small footprint

- Utility Requirements

- Straightforward

- Working mechanism

- Citrus extraction

- Integrated steps

- Juice extraction to delivery to pasteurizer

- CIP/SIP

- Simple clean-up system in place

- Automation level

- Manual / PLC controlled

- Batch vs. continuous operation

- Batch / Inline Continuous

- Changeover time

- Less costly and time with small footprint

- Corrosive resistance (e.g. acids)

- Yes/No

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Fruit size compatibility

- Pre-sized to bulk

- Footprint

- Compact skid-mounted

- System Configuration

- Single, Double, Multiple extractor

- Discharge method

- Juice delivery to pasteurizer or storage

- Control panel type

- PLC-controlled

- Footprint

- Compact skid-mounted

- Extractor configurations

- Single, double, multiple

- Fruit handling

- Pre-sized fruit to bulk raw material

- Extractor cup options

- Multiple options available

- Integration possibilities

- Compatible with pasteurization and storage facilities