Laboratory homogenizer for dairy and biotech applications

Ensure precise particle size reduction and consistent texture in your emulsions and dispersions with a state-of-the-art laboratory solution, ideal for scaling from research to production while handling abrasive and viscous products efficiently.

Processes and Homogenizes Liquid and Slurry Products

The ATOMO 3.0 from Bertoli, a brand of INTERPUMP GROUP, is a robust solution designed for precise homogenization and pumping in industrial applications. With its three plunger-based design, this table-top unit excels in processing both viscous and abrasive materials. Delivering up to 200 liters per hour at 600 bar, it’s ideal for producing milk smoothies, nanoparticle dispersions, and skincare lotions. The ATOMO 3.0 integrates seamlessly into R&D and pilot scales, offering configurations compliant with ATEX standards for explosive environments. Featuring DIN 11851 welding flanges, the unit ensures reliable product transfer and supports efficient scaling from test to full production. For ease of maintenance, it’s equipped with a simple lubrication system and uses only 30 liters of water per hour. Additionally, its stainless-steel construction provides durability and resistance to corrosion, supporting a wide range of chemical and biotech applications.

Benefits

- Ensures consistent product quality with precise homogenization for diverse end products.

- Supports scalability from laboratory tests to full production, minimizing transition time.

- Reduces production costs with efficient handling of abrasive and viscous materials.

- Enhances safety in volatile environments with ATEX-compliant configurations.

- Lowers maintenance needs with efficient water usage and simple lubrication systems.

- Applications

- Pharma and biotech, Cosmetic, Chemical and nano dispersion, Food and beverage, Dairy

- End products

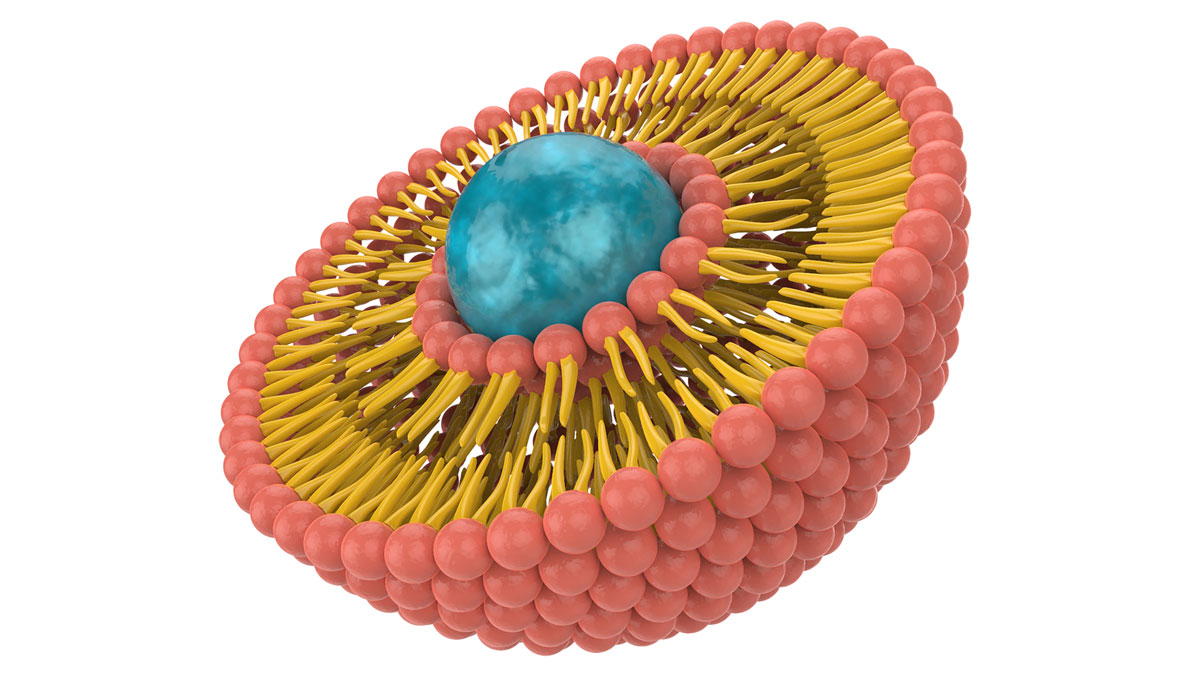

- Skincare creams, Tinctures, Nanoparticles, Protein shakes, Almond milk, Soy milk, Milk smoothies, Yogurt drinks, Lotion emulsions, Liposomes, Liquid vaccines, Fruit juices

- Steps before

- Mixing, Pre-heating, Initial Formulation

- Steps after

- Cooling, Packaging, Pasteurization

- Input ingredients

- abrasive products, viscous products, dairy, food and beverage, chemical and nano dispersion, cosmetic, pharma and biotech

- Output ingredients

- homogenized dairy, homogenized food and beverage, homogenized chemical products, homogenized cosmetics, homogenized pharmaceuticals

- Market info

- Bertoli, part of the Interpump Group, is known for its expertise in designing and manufacturing high-pressure homogenizers and positive displacement pumps, serving industries like food processing, pharmaceuticals, and cosmetics, with a reputation for reliability and innovation.

- Power

- 4 kW

- Pressure

- 1, 500 bar

- Capacity

- 200 l/h at 600 bar

- Plunger Number

- 3

- Water Consumption

- 30 l/h

- Lubrication Oil Quantity

- 2 kg (SAE 85W-90)

- Weight

- 180 kg

- Connection Product Inlet/Outlet

- Welding flanges DIN 11851

- Working Mechanism

- Three Plungers

- Flow Type

- Inline Continuous

- Scale-Up Capability

- Reliable from Test to Production

- Automation Level

- Manual / PLC-controlled

- Product Suitability

- Abrasive and Viscous Products

- Configuration Options

- Available Atex and Skid Versions

- Cleaning Method

- CIP-compatible

- Abrasion resistance

- Yes

- Biological compatibility

- Yes

- Cleanability

- High

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Table top design

- Plunger number

- 3

- Maximum capacity

- 200 l/h

- Pressure

- Up to 1500 bar

- Weight

- 180 Kg

- Water consumption

- 30 l/h

- Lubrication oil quantity

- 2 kg (SAE 85W-90)

- Connection product inlet/outlet

- Welding flanges DIN 11851

- Configuration

- Available Atex configuration

- Version

- Available Skid version

- Product compatibility

- Suitable for abrasive and viscous product