Self-adhesive labeling for glass and Pet bottles and beverage cans

Maximize your production efficiency with a labeling machine designed for high-speed operations. Perfect for a variety of container types, it ensures uninterrupted, precise labeling—ideal for producers looking to enhance their packaging line’s performance while maintaining a high-quality brand image.

Labels and Aligns Bottles and Cans

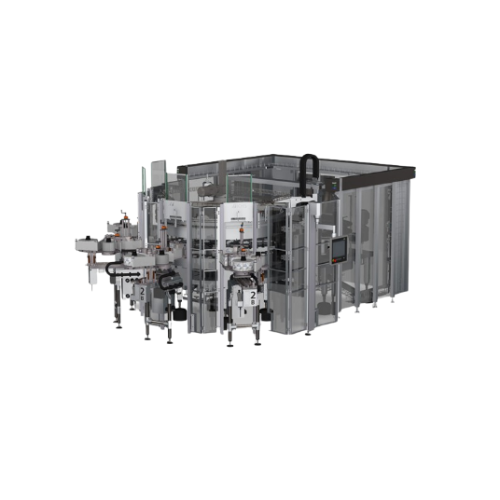

The Innoket Neo SK from KHS Group is a versatile labeling machine designed for precision in high-speed packaging lines. Integrating seamlessly into both new and existing setups, it labels up to 60,000 bottles per hour, accommodating containers from glass to PET, and even beverage cans. Featuring advanced, non-stop tandem operation, it optimizes efficiency with minimal operator intervention. The machine’s flexible positioning allows for labeling both before and after filling, supporting various production flows. The use of cutting-edge components reduces energy consumption, while its compatibility with wash-off self-adhesive labels supports sustainable practices. Ideal for beverage and non-food industries, it ensures brand competitiveness with application options ranging from lager beer and mineral water bottles to energy drink cans and olive oil PET bottles.

Benefits

- Enhances production speed with non-stop, high-capacity labeling operations.

- Minimizes manual oversight, freeing up labor resources through automated tandem operation.

- Lowers energy costs due to improved low-consumption components.

- Increases flexibility in production line layout with adaptable labeling position.

- Supports sustainable practices with recyclable label options.

- Applications

- Food, Liquid food, Pet bottles, Wine, Milk, Nonfood, Beverage cans, Iced tea, Spirits, Still water, Homecare products, Juice, Soft drinks, Beer, Sparkling wine, Glass bottles

- End products

- Energy drink cans, Champagne bottles, Bottled red wine, Vodka bottles, Lager beer, Canned soup, Mineral water bottles, Orange juice bottles, Liquid soap, Carbonated soft drinks, Dishwasher liquid, Whole milk cartons, Olive oil pet bottles, Bottled iced green tea

- Steps before

- Filling, Container preparation, Container alignment

- Steps after

- Packaging, Quality inspection, Intralogistics

- Input ingredients

- glass bottles, PET bottles, beverage cans, film labels, containers

- Output ingredients

- labeled glass bottles, labeled PET bottles, labeled beverage cans, transparent film labels, 'no-label' look containers

- Market info

- KHS is known for manufacturing innovative filling and packaging systems for the beverage, food, and non-food industries, renowned for their engineering expertise, high-quality standards, and sustainable solutions in ensuring efficient production processes.

- Labeling Speed

- Glass and PET

- Cans

- up to 35, 000 containers/hour

- Container Compatibility

- Conical or cylindrical

- PET,glass,or cans

- Automation

- Tandem version for uninterrupted autochange mode

- Label Placement Accuracy

- Camera-controlled container alignment (optional)

- Energy Consumption

- Low energy consumption

- Integration Capability

- Can be integrated into existing lines

- Operation Mode

- Continuous, interruption-free (tandem version)

- Automation Level

- Non-stop operation (tandem version)

- Label Placement

- Camera-controlled container alignment (optional)

- Labeling Flexibility

- Labeling of full or empty cans

- Output Capacity

- 60, 000 bottles or 35, 000 cans per hour

- Energy Efficiency

- Low energy consumption

- Sustainability

- Compatible with wash-off self-adhesive labels

- Placement Flexibility

- Upstream or downstream of the filler

- Material types

- Glass / PET / Metal (cans)

- Corrosive resistance

- Sustainable wash-off labels

- Lightweight

- Lightweight PET

- Recyclability

- Compatible with recyclable barriers

- Tethered caps

- Compatible with tethered caps systems

- Container type

- Glass / PET / Cans

- Container shape

- Conical / Cylindrical

- Label type

- Self-adhesive / Transparent Film

- Output capacity

- 35k–60k/hr

- Container type

- Glass / PET / Can

- Output capacity

- 60, 000 bottles/hour for glass and PET, 35, 000 cans/hour

- Label type

- Self-adhesive printed transparent film

- Packaging configuration

- Double station array (tandem version)

- Energy consumption

- Low energy due to cutting-edge components

- Compatibility

- Returnable containers with wash-off self-adhesive labels

- Flexibility

- Processes conical or cylindrical containers

- Control panel type

- HMI / Touchscreen

- Integration possibilities

- Camera-controlled container alignment

- Flexible positioning

- Upstream/Downstream of the filler