High-pressure homogenizers for dairy and food products

Achieve consistent texture and stability in your liquid products with our high-pressure homogenizers, designed to improve shelf life and flavor by breaking down fat globules and agglomerates. Perfect for enhancing the quality of dairy, beverages, and emulsions in your production line.

Processes and Emulsifies Liquids for Diverse Applications

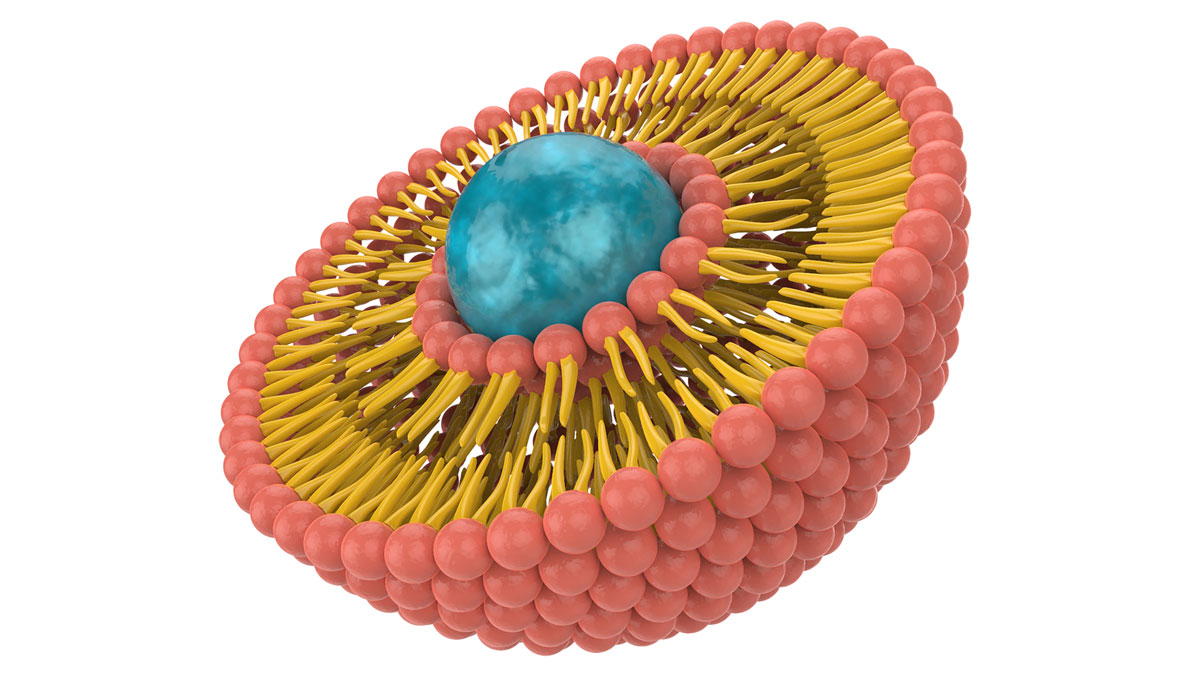

The HST High-Pressure Homogenizer Series from HST Maschinenbau GmbH is an engineered solution tailored for liquid processing across diverse industries. Utilizing a pressurized, ring-shaped gap to apply turbulent and laminar forces, it efficiently breaks down fat globules and agglomerates, ensuring even distribution for superior product consistency and stability. This homogenizer is ideal for applications ranging from food products like UHT milk and creams to pharmaceutical formulations such as intravenous emulsions and cosmetic creams. Models within the series can handle capacities from 300 liters per hour up to an impressive 80,000 liters per hour, offering flexibility in both pilot and full-scale production environments. With options for aseptic designs and noise reduction cladding, this series integrates seamlessly with existing systems, supporting continuous operations with enhanced energy efficiency. Constructed with materials like high-strength stainless steel and ceramics, the homogenizers ensure durability and corrosion resistance, compliant with industry standards. Customizable configurations and comprehensive engineering support further enhance its adaptability to specific processing needs, while maintenance is streamlined through easy access components and service options.

Benefits

- Enhances product stability and texture with efficient particle size reduction.

- Adapts to various processing needs with customizable configurations and material options.

- Lowers operational noise and vibration, ensuring a smoother production environment.

- Optimizes energy use, contributing to reduced power consumption in continuous operations.

- Meets industry standards with aseptic design options, ensuring safety and compliance.

- Applications

- Cream, Food industry, Baby and infant food, Ointments, Colours, Dyes, Uht milk, Ingredients, Textures, Cell disruption, Chemicals industry, Beauty creams, Insecticides/herbicides, Mixed ice cream, Liposomes, Resin dispersions, Fruit juices, Fuels/water emulsions, Latex, Nanosomes, Pigment dispersions, Pharmaceutical and cosmetics industry, Vegetable juices, Condensed milk, Egg products, Special drinks, Fresh milk, Ketchup, Intravenous emulsions, Yoghurt, Wax emulsions, Sauces and dressings, Lubricants

- End products

- Infant formula, Fragrance compounds, Greek yogurt, Carrot juice, Foundation creams, Pesticide suspensions, Whole milk, Epoxy resin coatings, Liquid egg whites, Caesar dressing, Nanostructured liposome carriers, Orange juice, Isotonic sports drinks, Vanilla ice cream, Carnauba wax polish, Whipping cream, Evaporated milk, Hair dye formulations, Dermal textures, Parenteral nutrition solutions, Ultra-high temperature processed milk, Engine lubricants, Medical ointments, Red dye solutions, Textile dyes, Insulin for cell culture, Nanoparticle delivery systems, Diesel emulsions, Natural rubber latex products, Tomato ketchup

- Steps before

- Heat treatment, Product heating

- Steps after

- Creaming stability enhancement, Packing, Emulsification, Mixing

- Input ingredients

- fresh milk, cream, vegetable juices, UHT milk, yoghurt, baby and infant food, condensed milk, ketchup, sauces and dressings, mixed ice cream, fruit juices, egg products, special drinks, intravenous emulsions, liposomes, ingredients, textures, beauty creams, dyes, ointments, cell disruption, pigment dispersions, lubricants, fuels/water emulsions, wax emulsions, insecticides/herbicides, resin dispersions, nanosomes, colours, latex

- Output ingredients

- stabilized emulsions, evenly distributed fat globules, homogenized product, consistent textures, enhanced shelf life, improved colour intensity, flavour consistency, creaming stability

- Market info

- HST Maschinenbau is known for its expertise in designing and manufacturing custom-engineered industrial machinery, particularly in the sectors of hydraulics and automation, with a strong reputation for quality and innovative solutions tailored to client needs.

- Capacity

- 300l/h until 35.000l/h

- Capacity

- 8.000 - 14.000l/h and up to 80.000l/h

- Capacity

- 10.000l/h – 200bar

- Power range

- 5, 5 - 250kW

- Power range

- 55-90kW and 400kW

- Power range

- 3-75kW

- Design option

- Aseptic

- Design option

- ATEX

- Noise insulation

- Noise insulation cladding

- Valve type

- PLUG, PILOTED, Multigap

- Valve control

- Pneumatically or hydraulically

- Working Mechanism

- High-pressure homogenization

- Batch vs. Continuous Operation

- Continuous

- Automation Level

- Pneumatically or hydraulically controlled

- Energy Efficiency

- Reduced energy consumption

- Noise Insulation

- Noise insulation cladding

- Water Consumption

- Reduced in Integrated series

- Abrasion resistance

- High-strength stainless steels, sintered materials, ceramics

- Biological compatibility

- Yes

- Cleanability

- CIP / SIP capable

- Corrosive resistance (e.g. acids)

- High-strength stainless steels, ceramics

- Control panel type

- Pneumatic / Hydraulic

- Discharge method

- Turbulent and laminar forces

- Compact footprint

- Robust design

- Piston versions

- Standard, Chrome-plated, Ceramic, HST special coating

- Homogenizing valves

- PLUG, PILOTED, Multigap

- Aseptic design

- Available

- ATEX design

- Available

- Piston material

- Adaptable based on product

- Packing system

- Tailored for product properties

- Machine series

- Standard, Integrated, Economy