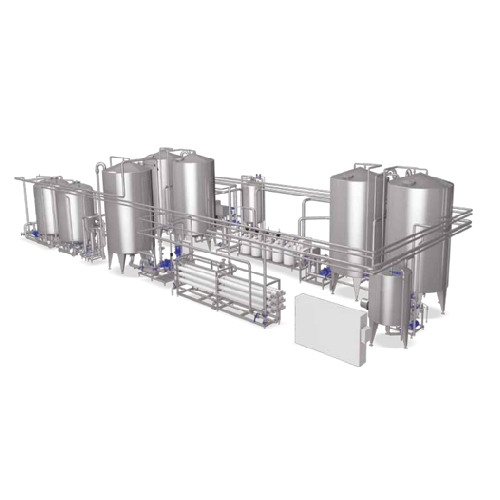

Versatile industrial water disinfection system

Ensuring optimal water disinfection is crucial for beverage manufacturers seeking to maintain high-quality standards while preventing microbial contamination.

Disinfects and Sterilizes Water and Beverages

A Due S.p.A. offers comprehensive water disinfection solutions designed for the beverage and bottling industries. These systems utilize chlorine dosing, ozone dosage, and UV irradiation to ensure effective pathogen elimination. The integration of specialized dosing pumps and electromagnetic flow meters enables precise chemical management, maintaining optimal residual chlorine levels. The EASY.Ozone system features strong oxidizing properties, ensuring sterilization across a wide pH range, while UV sterilization operates with 316L stainless steel chambers, achieving significant microbial reductions with a 40 mJ/cm² UV dose. Capable of treating from 10,000 to 100,000 liters per hour, these systems support continuous or semi-automatic operation and seamlessly integrate within existing production lines. Customizable options include contact tank configurations and in-line micro-dosage capabilities to meet diverse industry needs, ensuring safety and compliance while minimizing operational costs.

Benefits

- Enhances product safety by eliminating 99.99% of harmful microorganisms without chemical residues.

- Adapts to varying production demands with customizable flow rates from 10,000 to 100,000 liters per hour.

- Minimizes operational costs with precise chemical usage, reducing waste and ensuring compliance.

- Supports continuous production with automatic start-stop management and easy integration.

- Extends equipment lifespan with corrosion-resistant materials and efficient sterilization cycles.

- Applications

- Beverages, Water, Milk, Non-alcoholic beer, Plant-based, Flavored water, Juices, Carbonated soft drinks, Hard seltzers

- End products

- Carbonated lemon-lime soda, Bottled water, Orange juice, Almond milk, Sparkling water, Lemon-flavored water, Hard seltzer with grapefruit flavor, Non-alcoholic lager beer

- Steps before

- Water Filtration, Water Clarification, Water Remineralization

- Steps after

- Bottling, Filling, Packaging

- Input ingredients

- Water, Sodium Hypochlorite, Ozone, UV Light, Chlorine

- Output ingredients

- Disinfected Water, Residual Chlorine, Residual Ozone, Sterilized Bottles

- Market info

- A Due is known for designing and manufacturing beverage processing equipment, specializing in water treatment, syrup preparation, and complete automation solutions for the beverage industry, with a strong reputation for innovation and quality engineering.

- Automation

- Fully automatic / Semi-automatic

- Flow rate

- 10, 000 l/h to 100, 000 l/h

- UV Dose

- 40–120 mJ/cm²

- UV Wavelength

- 253 nm

- Contact Time

- 3 to 5 minutes

- Sodium Hypochlorite Dosage

- 0.5 up to 10 l/h

- Residual Ozone Quantity

- 0.2–1 ppm

- Residual Chlorine

- 1 to 5 PPM

- Operation Time

- p to 12, 000 hours

- Working mechanism

- UV, Chlorine, Ozone

- Automation level

- Manual / Semi-Automatic / Fully Automatic

- Contact time

- 3–5 min (Ozone)

- Batch vs. continuous operation

- Continuous

- Flow rate compatibility

- 10, 000 l/h to 100, 000 l/h

- Water flow control

- Electromagnetic flow meter

- Corrosive resistance (e.g. acids)

- Stainless steel 316L

- Biological compatibility

- UV sterilization

- Cleanability

- CIP compatibility (hot version available)

- Tank shape and size

- Contact tank for chlorine and ozone

- Material type

- 316L stainless steel for UV chamber

- Flow rate range

- 10, 000 l/h to 100, 000 l/h

- UV Lamp type

- 253 nm wavelength

- Control panel type

- Manual / Auto / SCADA

- Integration possibilities

- Inline / Stand-alone

- Ozone dosage adjustment

- Proportional to water characteristics

- UV lamp compatibility

- Various brands

- System automation

- Fully / Semi-automatic

- Cooling version

- Available

- Start,Stop management

- Automatic