Industrial weight tracking system for injected products

Optimize your production line by accurately tracking product weight variations pre- and post-injection, ensuring precise ingredient incorporation and efficient process control.

Weighs, Records, and Injects Products Accurately

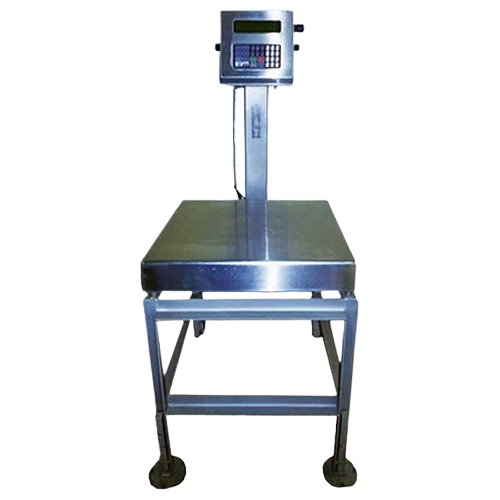

The C.A.T. Pick-Up Injection Weighing Scale by Cooling & Applied Technologies is designed to enhance precision in food processing operations. This scale is equipped to weigh products before and after the injection process, automatically calculating and recording the percentage of injected material with a time/date stamp for seamless traceability. It is particularly suited for applications involving poultry, meat, seafood, and plant-based proteins, ensuring consistency in end-products like chicken breasts and plant-based burger patties.

The scale operates with a 250 lb. load cell on a 20 x 20 base, constructed from stainless steel for robustness and longevity. Its adjustable frame with rear casters facilitates easy mobility within processing and packaging environments. The system supports USB data collection, simplifying integration into existing digital infrastructures for efficient data management and compliance reporting.

Engineered for manual and continuous high-speed operations, the C.A.T. Pick-Up Scale is a vital component for food processing companies aiming to optimize their production efficiency. With its capacity for accurate data recording and injection handling, it directly contributes to improved process control and product quality assurance in demanding industrial settings.

Benefits

- Ensures product consistency by precisely calculating and recording injection percentages.

- Streamlines data management with automatic USB data collection and integration.

- Enhances mobility and adaptability with an adjustable frame and rear casters.

- Increases process efficiency in high-speed operations with continuous weighing and injection capabilities.

- Supports regulatory compliance with accurate and time-stamped data for traceability.

- Applications

- Seafood, Ready meals, Beverages, Sauces, Pet food, Meat, Bakery, Confectionery, Fruits, Nuts, Plant-based protein, Dressings, Vegetables, Poultry, Seasonings, Juices

- End products

- Dry dog food, Chicken breasts, Canned peaches, Beef steak, Orange juice, Microwaveable ready meals, Plant-based burger patties, Iced tea, Chili seasoning, Freshly cut carrots, Shrimp cocktail, Croissants, Chocolate bars, Tomato sauce, Ranch dressing, Almond snack packs

- Steps before

- Brine Preparation, Fresh Cut Technologies, Injection Equipment, Grinding, Mixing

- Steps after

- Weighing, Bagging, Postharvest Processing, Portioning, Slicing, Packaging

- Input ingredients

- raw product, non-injected product

- Output ingredients

- injected product, data record, USB data

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Base size

- 20 x 20

- Load cell capacity

- 250 lb.

- Material construction

- Stainless steel

- Data collection method

- USB

- Automation level

- Auto recording / USB data collection

- Batch vs. continuous operation

- Batch

- Data integration

- USB data upload

- Frame adjustability

- Adjustable frame with rear casters

- Load measurement

- 250 lb. load cell

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Cleanability

- Easy to clean surfaces

- Base size

- 20 x 20 inches

- Load capacity

- 250 lb

- Construction material

- Stainless steel

- Frame adjustability

- Adjustable frame with rear casters

- Control panel type

- Intuitive interface

- Data integration

- USB data export

- Mobility

- Adjustable frame with rear casters