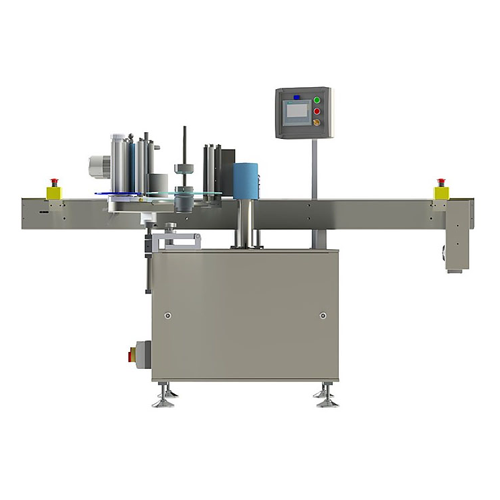

High precision three-roller wraparound labeller

Achieve precise label placement on round containers effortlessly with a three-point contact system designed to eliminate common imperfections such as creasing and bubbling. Ideal for high-quality applications, this labelling solution ensures consistency and reliability in demanding production environments.

Applies Labels with Precision and Efficiency

The P120 Three-Roller Wrap Labelling Machine from Adelphi offers a robust solution for precise labelling needs across various industries. Designed specifically for wrapping labels around cylindrical containers, it eliminates label creasing and bubbling, ensuring consistent application quality. The machine features a high-speed output of up to 40 labels per minute and accommodates containers from 20mm to 150mm in diameter, making it versatile for applications in cosmetics, pharmaceuticals, and more. It integrates effortlessly with existing production lines, supporting both single and dual label feed functions, and includes an optional coding system for enhanced functionality. Engineered for both semi-automatic and entry-level operations, the P120 ensures ease of maintenance with its simple change part system, making it ideal for small to medium enterprises and researchers requiring precision in label placement.

Benefits

- Enhances labelling precision by eliminating creasing and bubbling.

- Increases production speed with up to 40 labels per minute.

- Adapts to various container sizes, ensuring versatility across product lines.

- Simplifies maintenance with an efficient change part system.

- Integrates optional coding for comprehensive product labeling.

- Applications

- Personal care, Food, Research, Laboratory, Beverage, E-liquid, Household products, Oil, Cosmetics, Veterinary, Chemical, Lube oil, Agrochemical, Pharmaceutical

- End products

- Cosmetic creams, Sauce bottles, Medicine bottles, Vape juice bottles, Motor oil bottles, Chemical containers, Pesticide bottles, Pet supplements, Essential oil bottles, Juice bottles, Shampoo bottles, Detergent bottles

- Steps before

- Container Production, Product Filling, Quality Inspection

- Steps after

- Packing, Quality Assurance, Shipping

- Input ingredients

- round containers, glass products, 20mm to 150mm diameter containers

- Output ingredients

- wrapped labelled containers, up to 40 labelled containers per minute

- Market info

- Label placement accuracy

- Higher accuracy vs linear wrap systems

- Feed speed

- Up to 25 m/min

- Labeling speed

- Up to 40 labels per minute

- Container compatibility

- Round containers, 20mm to 150mm diameter

- Label application method

- Three-roller wrap system

- Label creasing/bubbling prevention

- Three-point contact design

- Label feed functionality

- Single or dual

- Optional coding and pitching system

- Available

- Designed and Manufactured

- Made in the UK

- Working mechanism

- Three-roller wrap system

- Integrated steps

- Label spotting placement

- Label placement accuracy

- Higher accuracy vs linear systems

- Head feed speed

- Up to 25 m/min

- Label application speed

- Up to 40 labels/min (Dependent on label length and product size)

- Change part system

- Simple

- Suitable container diameter

- 20mm to 150mm

- Optional systems

- Coding and pitching system available

- Label application system

- Three-roller wrap

- Container size compatibility

- 20mm to 150mm diameter

- Label feed functionality

- Single or dual

- Optional systems

- Coding and pitching

- Change part system

- Simple

- Label feed functionality

- Single or dual

- Label spotting placement

- Available

- Optional coding and pitching system

- Available