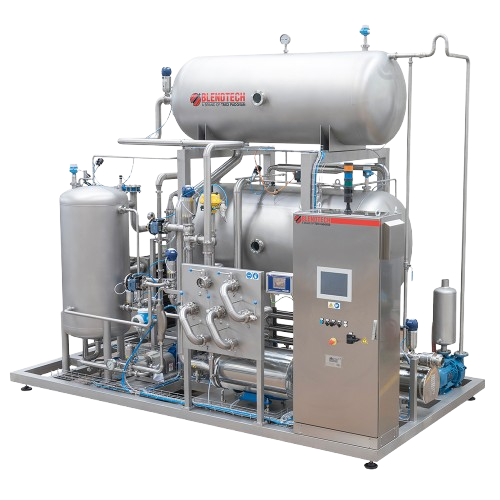

Blending system for fruit juices and soft drinks

Optimize your beverage production with precise blending and carbonation, ensuring consistent quality and flavor integrity in every batch of fruit juices and soft drinks.

Processes and Clarifies Liquid Products

Blendtech by TMCI Padovan offers comprehensive juice and soft drink processing equipment, addressing key industry challenges with its integrated filtration, blending, and pasteurization systems. Utilizing advanced multi-stage processes for filtration and clarification, it ensures high-quality end-products like juices and purees. Designed for fruit juice producers and soft drink manufacturers, this equipment handles diverse applications, such as orange juice, apple juice, and energy drinks, with exceptional precision. With high throughput capacity, it seamlessly integrates into your existing production line via PLC controls, optimizing energy use by up to 30%. Built with durable stainless steel, it resists corrosion while ensuring compliance with food safety standards. Easy maintenance is enabled through an integrated CIP system, reducing downtime and ensuring hygienic operation. Customizable features are available to match specific production requirements, supported by dedicated engineering assistance.

Benefits

- Enhances product quality with precise filtration and blending processes.

- Increases production efficiency by integrating seamlessly with existing systems.

- Lowers operational costs through optimized energy consumption.

- Ensures safety and compliance with industry regulations.

- Minimizes downtime with quick and efficient CIP cleaning systems.

- Applications

- Liquid formulations, Syrups, Purees, Soft drinks, Fruit juices

- End products

- Apple puree, Vitamin water, Apple juice, Strawberry syrup, Tomato puree, Orange juice, Maple syrup, Herbal extracts, Energy drinks, Cola drinks

- Steps before

- Purification, Drying, Emulsification, Grinding, Deaeration

- Steps after

- Packing, Coating, Sterilization, Tablet Pressing, Aseptic Filling

- Input ingredients

- fruit juice, soft drinks, syrup

- Output ingredients

- filtered juice, clarified juice, pasteurized juice, blended drinks, carbonated drinks, aseptic juice lines, evaporated products

- Market info

- BLENDTECH (Omnia Technologies) is known for manufacturing advanced engineered-to-order blending and processing equipment. Their expertise in customized solutions and reliability has earned them a strong reputation in the industrial equipment market.

- Filtration method

- Filtrazione e Chiarifica

- Thermal process

- Pastorizzazione, Scambio Termico

- Deaeration,Blending,Mixing

- Deaerazione, Blending, Miscelazione, Carbonicazione

- Evaporation,Desulfurization

- Evaporazione, Desolforazione

- Aseptic line

- Linee Asettiche

- Complete juice,puree line

- Linee complete succhi, puree

- Syrup room

- Sale sciroppo

- Working mechanism

- Filtration, Chiarifica, Pastorizzazione, Deaerazione, Blending, Miscelazione, Carbonicazione

- Integrated steps

- Filtration, Pasteurization, Mixing, Carbonation

- Automation level

- PLC / SCADA

- CIP/SIP

- CIP principles

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Viscosity

- Low/Medium/High

- Container size

- Small/Medium/Large

- Container shape

- Round/Square/Irregular

- Control panel type

- PLC / HMI

- Integration possibilities

- Seamless with existing systems

- Footprint Options

- Compact / Modular