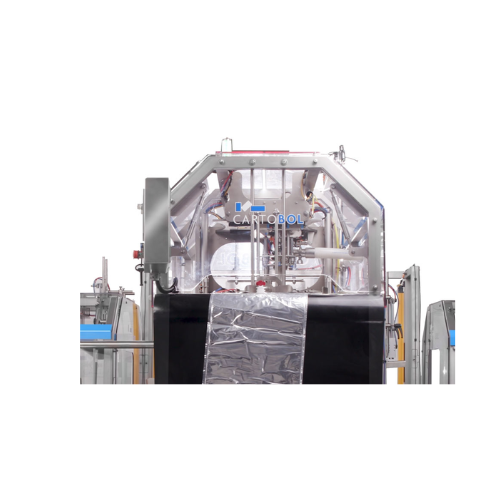

Bag-in-box fully automatic filling line

Streamline your liquid packaging operations with a modular system designed to enhance productivity and reduce labor by synchronizing carton erection, bag filling, packing, sealing, and palletizing in one continuous, high-speed process.

Streamlines Liquid Packaging and Palletizing

The Bag-in-Box Filling and Packaging Line from Cartobol integrates seamlessly into your production process to handle diverse liquid packaging needs. This fully automatic line is capable of erecting cartons, filling bags, packing, sealing, and palletizing. It’s ideal for applications like beverage, dairy, and wine packaging, and produces end-products such as Bag-in-Box juices and boxed water. The line efficiently manages high volumes and uses advanced automation technology for continuous operation, enhancing productivity while minimizing labor requirements. Its modular design allows for customization to suit specific industry needs, and it’s constructed with durable materials that ensure longevity and minimize maintenance.

Benefits

- Enhances efficiency by automating carton erection, filling, and palletizing, reducing manual labor needs.

- Increases packaging speed, ensuring high throughput with minimal production interruptions.

- Supports environmentally friendly packaging with Bag-in-Box solutions, aligning with sustainability goals.

- Customizable for specific industry applications, offering flexibility in production requirements.

- Durable construction minimizes maintenance downtime and extends equipment lifespan.

- Applications

- Sauce packaging, Industrial liquids, Beverage packaging, Liquid packaging, Food packaging, Wine packaging, Juice packaging, Water packaging, Dairy products

- End products

- Concentrated syrups in bag-in-box, Bag-in-box wines, Industrial oils in bag-in-box, Liquid sauces in bag-in-box, Bag-in-box juices, Boxed water, Purees in bag-in-box, Dairy creams in bag-in-box

- Steps before

- Carton Erecting, Bag Filling, Box Packaging Preparation

- Steps after

- Carton Packing, Carton Closing, Palletizing

- Input ingredients

- cartons, Bag-in-Box bags

- Output ingredients

- filled Bag-in-Box packages, palletized cartons

- Market info

- Cartobol is known for manufacturing industrial engineered-to-order (ETO) equipment, specializing in custom solutions tailored to specific client requirements. They have a strong reputation for innovation, quality craftsmanship, and delivering reliable, precise machinery suited for various industrial applications.

- Automation

- Fully automatic

- Modular Design

- Yes

- Palletising System

- Cartesian axis palletiser

- Filling Line Components

- Carton erector, bag filler, carton packing system, hot-melt carton closer

- Carton Erector Model

- ECOPACK MASTERFORM SV

- Bag Filler Model

- ECOFILL MASTER

- Carton Closer Model

- ECOPACK HOTMELT

- Palletiser Model

- SPEEDBOX

- Modularity

- Yes

- Synchronization Capability

- Yes

- Automation level

- Fully Automatic

- End-of-line integration

- Cartesian axis palletiser

- Filling method

- Automatic Bag-in-Box bag filler

- Carton packing

- Automatic with funnel

- Carton Closing

- Automatic hot-melt carton closer

- Productivity

- Increased by integration

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product type

- Liquids / Semi-liquids

- Packaging type

- Carton

- Machine footprint

- Modular design

- Carton erector model

- ECOPACK MASTERFORM SV

- Bag filler model

- ECOFILL MASTER

- Hot-melt carton closer model

- ECOPACK HOTMELT

- Palletiser model

- SPEEDBOX

- Carton packing system

- With funnel

- Control panel type

- PLC / HMI / Touch screen

- Integration possibilities

- Modular system for productivity and workforce reduction

- Filling line components

- Automatic carton erector, bag filler, packing system, hot-melt closer

- End-of-line options

- Cartesian axis palletiser

- Application scale

- Fully automatic