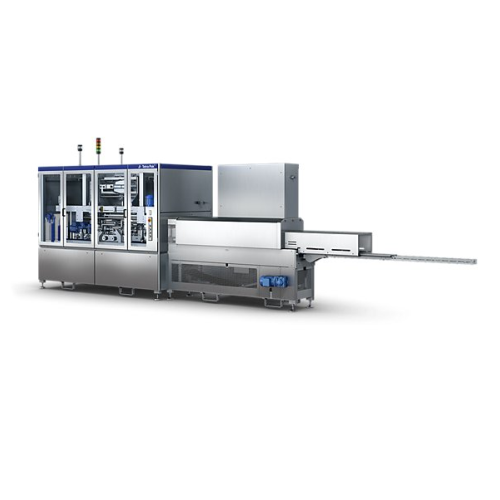

Shrink wrapping system for flex portion packages

Optimize your packaging line with a high-speed shrink wrapping system designed for seamless film wrapping and precise sealing, ensuring secure multipacks without manual intervention and reducing downtime with quick changeovers.

Wraps and Secures Diverse Product Packages

The Tetra Pak® Shrink Wrapper 40 Flex is a versatile film packaging machine designed to enhance your production line’s efficiency. Utilizing shrink technology, it provides a robust solution for securely wrapping a wide range of products, including dairy, beverages, and ready-to-eat foods. This machine excels in packaging integrity, featuring a quick-change system for different package patterns without the need for tools. The automatic conveyor lubrication and alarm tower with quick action buttons ensure continuous operation, minimizing downtime. The Shrink Wrapper 40 Flex is capable of seamless integration into existing lines, equipped with PLC-controlled settings and real-time monitoring options. It operates with standard films and offers a 2D design correction system for perfect printed film alignment, reducing waste and ensuring high-quality appearance. Customizable options and engineering support are available to meet specific production needs, making it a valuable asset for packaging departments aiming to maintain product consistency and reduce operator handling.

Benefits

- Ensures consistent package quality and integrity, reducing the risk of product damage during transit.

- Minimizes downtime with rapid, tool-free package pattern changes and quick action controls.

- Optimizes resource use with automatic conveyor lubrication, enhancing operational efficiency.

- Reduces material waste with precise film alignment and a 2D design correction system.

- Integrates seamlessly with existing production lines, supporting high-speed, continuous operations.

- Applications

- Food, Nectar, Infant formula, Non-food products, Still drinks, Cheese, Alcoholic beverages, Plant-based products, Powder, Ice cream, Dairy alternative, Juice, Prepared foods, Dairy

- End products

- Beer multipacks, Soy milk packaging, Still drink bottles, Milk cartons, Juice boxes, Ice cream tubs, Nectar packages, Cheese blocks, Almond milk cartons, Plant-based yogurt containers, Protein powder pouches, Baby formula cans, Detergent bottles

- Steps before

- Package formation, Film selection, Product cooling, Conveyor setup

- Steps after

- Storage, Distribution, Retail shelving, Quality inspection

- Input ingredients

- standard films, packages

- Output ingredients

- shrink-wrapped packages, film-wrapped packages

- Market info

- Tetra Pak is renowned for providing innovative packaging solutions, specializing in carton packaging for the food and beverage industry. It is esteemed for high-quality, sustainable, and efficient processing and packaging equipment on a global scale.

- Automation

- PLC-controlled

- Package pattern changeover

- Fast and accurate

- Film compatibility

- Standard films

- Package infeed

- Stable with automatic conveyor lubrication

- Reel splice sealing

- Automatic sealing without manual taping

- 2D design correction system

- Available as an option

- Alarm system

- Alarm tower with quick action buttons

- Color coded settings

- Green, Orange, Blue

- Production safety

- Won't start outside setting range

- Changeover adjustments

- No tools needed

- Working mechanism

- Shrink technology

- Integrated steps

- Film wrapping, package infeed

- Automation level

- PLC

- Changeover time

- Fast and accurate

- Cleaning method

- Manual

- CIP/SIP

- No

- Energy efficiency

- Optimized for minimal downtime

- Alarm system

- Tower with quick action buttons

- Film type compatibility

- Standard films

- Package size adaptability

- Green

- Orange

- package width

- Film wrapping method

- Shrink technology

- Package unit appearance

- High quality

- Infeed method

- Robust package infeed

- Conveyor lubrication

- Integrated automatic lubrication

- Side flaps

- Prevents package bouncing

- Display settings

- Displays set and current values

- Color coded settings

- Green

- Reel splice sealing bar

- Eliminates manual taping

- 2D design correction system

- Option for printed film

- Control panel type

- Setting Displays

- Color coded settings

- Green

- Orange

- package width

- Blue

- package type

- 2D design correction system

- Improved calibration and contrast reading for printed film