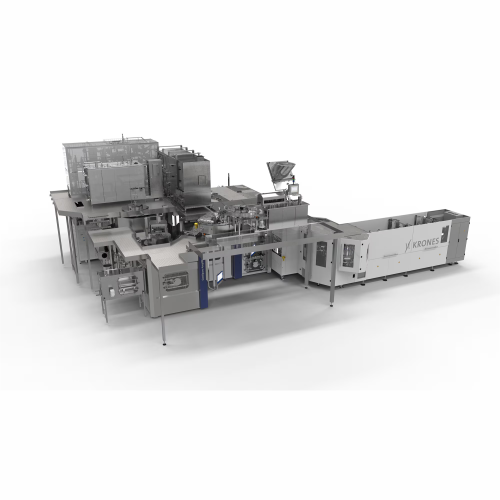

Ultrahygienic block for aseptic filling

When handling sensitive beverages, ensuring microbiological safety and quick production is crucial; this solution offers rapid aseptic filling, sterilizing both the product and containers efficiently, minimizing downtime and enhancing production reliability.

Sterilizes, Blows, Moulds, Fills, and Caps PET Containers

The Contipure Bloc P from Krones is an advanced aseptic filling solution designed for high-volume production facilities specializing in sensitive products. This system integrates seamlessly with PET bottling lines due to its contiguous preform sterilization, blow molding, and capping capabilities. Its preform sterilization module employs gaseous hydrogen peroxide (H₂O₂) for comprehensive internal and external sterilization of containers, ensuring microbiological safety for products like lactose-free milk, juices, and plant-based beverages. With the capacity to fill up to 72,000 containers per hour, the system supports flexible production, handling both standard and lightweight PET containers with ease. Automation is key, with servo-controlled operations and optional tool-free quick-change capabilities that minimize downtime. The inclusion of a cap sterilization module ensures each cap’s integrity, utilizing ionized air and H₂O₂ without causing deformation. Energy efficiency is optimized through features like infrared ovens with low dead spaces and parabolic mirrors. Compatible with a wide range of liquid products, from carbonated soft drinks to protein-infused water, the Contipure Bloc P is ideal for manufacturers prioritizing product safety, efficiency, and flexibility. It offers robust support for cleaning and maintenance through efficient CIP systems, ensuring rapid and effective sanitation cycles to maximize uptime.

Benefits

- Enhances production efficiency by reducing change-over times to under 20 minutes.

- Ensures microbiological safety with rapid sterilization cycles, minimizing contamination risks.

- Supports high-volume output, filling up to 72,000 containers per hour.

- Lowers operational costs through energy-efficient infrared and servo-controlled systems.

- Increases production flexibility, accommodating a wide variety of liquid and bottle types.

- Applications

- Beverages, Water, Rpet containers, Pet containers, Milk and milk-based drinks, Sensitive products, Plant-based milk alternatives, Fruit pieces in beverages, Juices, Aseptic filling, Soft drinks

- End products

- Ready-to-drink iced tea, Functional energy drinks, Cold-pressed fruit juices, Apple juice, Strawberry banana smoothie, Vegan oat milk, Protein-infused water, Orange juice, Almond milk, Soy milk, Smoothies with mango pieces, Sparkling water, Pasteurized milk, Ultra-filtered milk, Lactose-free milk, Carbonated soft drinks, Rpet bottled mineral water, Flavored water

- Steps before

- Preform sterilisation, Preform feeding, Cap sorting, Preform drying

- Steps after

- Filling, Capping, Aseptic packing

- Input ingredients

- PET preforms, caps, sensitive products

- Output ingredients

- sterilised PET bottles, filled PET containers

- Market info

- Krones is renowned for its expertise in manufacturing beverage and liquid food processing and packaging equipment, offering comprehensive solutions that include filling, packaging technology, and processing systems, and is reputed for innovation and quality in the industry.

- Output

- Up to 72, 000 containers per hour

- Container type

- Round, square and rectangular PET containers

- Container size

- Standard and lightweight containers

- Filling method

- Aseptic filling

- Sterilisation method

- Gaseous hydrogen peroxide (H₂O₂)

- Changeover time

- Under 20 minutes

- Cleaning and sterilisation time

- 90 minutes including cleaning and sterilisation

- Intermediate sterilisation time

- 30 minutes

- Continuous operation time

- Up to 120 hours

- Aseptic capabilities

- Sterilises inside, outside, and neck area of preforms

- Automation

- Fully-automatic change-over

- Servo-controlled drives

- Every capping head has its own separate servo drive

- Automation level

- Fully-automatic

- Batch vs. continuous operation

- Continuous

- Changeover time

- Under 20 minutes

- CIP/SIP

- Hot caustic and steam

- Cleaning method

- Automatic CIP/SIP

- Energy efficiency

- Optimized for energy usage

- Pinpoint production

- Filling to the last drop

- High availability

- Up to 120 hours continuous operation

- Sterilization time

- 90 minutes total

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Preform sterilisation module

- Contipure D

- Cap sterilisation module

- Capsept D

- Preform feed system

- Contifeed

- Servo-controlled oven

- Yes

- Infrared oven

- Contiform standard series

- Protective plates quick-change

- Tool-free

- Aseptic filler and capper

- Yes

- Output adjustability

- Up to 72, 000 containers per hour

- Flexible production

- Automation package for change-overs

- High availability

- Up to 120 hours continuous operation

- Aseptic capper drive

- Separate servo drive