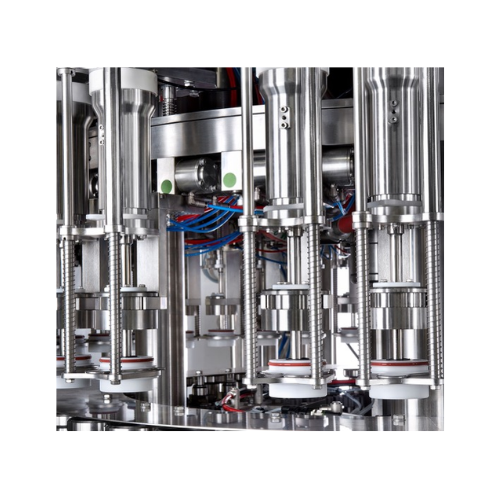

No-oxygen wine filler

Ensure product integrity with advanced no-oxygen filling systems, designed to preserve delicate flavors and prevent oxidation throughout the bottling process.

Fills Beverages While Minimizing Oxygen Exposure

Gruppo Bertolaso’s filling systems are engineered to maintain beverage integrity by minimizing oxygen exposure and contamination in the bottling process. Designed for use with wines, spirits, juices, and waters, these systems incorporate advanced no-oxygen and isobaric filling technologies. Central to their operation is the electropneumatic filling system, which utilizes innovative filling valves that ensure wines and beverages remain free of oxidization, preserving their distinct qualities. Suitable for high-speed and continuous production lines, the equipment integrates seamlessly with existing packaging operations, featuring automatic filling, rinsing, and corking processes. These systems are crafted from AISI 316 stainless steel, enhancing corrosion resistance and ensuring long-term durability. Bertolaso’s dedication to precision engineering offers producers customizable solutions, supporting efficiency and quality across the beverage industry.

Benefits

- Preserves beverage quality by preventing oxidation and contamination.

- Aligns with high-capacity production demands, streamlining operations.

- Lowers operational costs via efficient energy consumption.

- Adaptable to various beverages, enhancing production versatility.

- Constructed for durability and reliability in demanding environments.

- Applications

- Water, Wine, Spirits, Drinks, Juices

- End products

- Rosé wine, Still wines, Bottled water, Apple juice, Slightly sparkling wines, Sparkling wines, Whiskey, Red wine, Orange juice, Grape juice, Sparkling water, Carbonated drinks, White wine, Brandy, Vodka

- Steps before

- Wine treatment, Bottle rinsing

- Steps after

- Corking, Packing

- Input ingredients

- wine, still wine, slightly sparkling wine, sparkling wine, spirits, juices, drinks, water

- Output ingredients

- filled wine bottles, filled spirits bottles, filled juices bottles, filled drinks bottles, filled water bottles

- Market info

- Bertolaso (Omnia Technologies) is renowned for manufacturing high-quality, engineered-to-order bottling and packaging machinery, with extensive expertise in providing customized solutions for wineries and the beverage industry, ensuring efficiency, precision, and reliability in production processes.

- Filling Method

- Gravity / Low Vacuum / Isobaric

- Container Type

- Wine Bottles / Glass / PET

- Automation

- Automatic

- Oxidation Protection

- No-Oxygen System

- Filling Cycle

- Optimized for Sparkling and Still Wines

- Filling Valve Material

- Aisi 316 Stainless Steel

- Pressure

- 0.3 bar Overpressure

- Oxygen Increase

- Zero Increase in Oxygen

- Production Efficiency

- High Specific Speed

- Environmental Contamination Control

- No Ambient Air Contact

- Gas Removal

- Electropneumatic System

- Filling System Type

- Gravity / Low Vacuum / Isobaric

- Product Protection

- Oxidation / Microbiological / Contamination

- Automation Level

- Automatic

- CIP/SIP

- Applicable

- Filling Environment

- No-Oxygen

- Integration Capability

- Bottling Cycle / Rinsing / Corking

- Oxidation sensitivity

- High

- Foaming tendency

- Low

- Container type

- Glass / PET

- Liquid viscosity

- Low to Medium

- Container shape

- Round / Square

- Heat sensitivity

- High

- Microbiological sensitivity

- High

- Filling purpose

- High-pressure / No-oxygen

- Footprint

- Varies depending on model

- Tank Material

- Aisi 316 Stainless Steel

- Filling Valve Design

- Newly Conceived Design

- Valve Material

- Aisi 316 Stainless Steel

- Pneumatic Components

- Electropneumatic Control

- Filler Type

- Gravity, Low Vacuum, Isobaric, Volumetric

- Control Panel Type

- User-Configurable

- Discharge Method

- No-Oxygen Design

- Filling system type

- Gravity / Low vacuum / Isobaric

- Oxygen management

- No-oxygen filling system

- Pressure handling

- Reduced overpressure to 0.3 bar

- Sanitation level

- Aisi 316 stainless steel

- Integration with bottling process

- Bottle rinsing, filling, corking