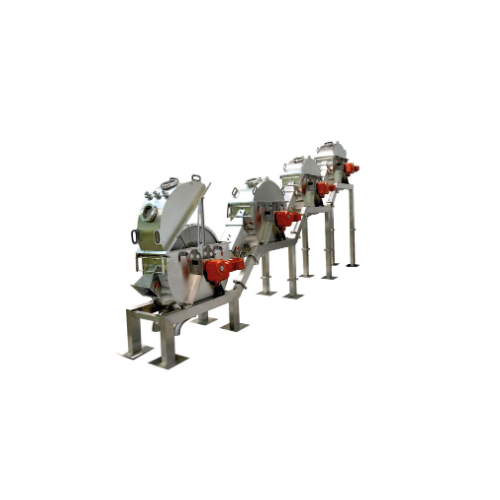

Continuous mash filtration system for breweries

Optimize your production line with continuous mash filtration that revolutionizes wort separation, enabling efficient extraction and flexibility in raw material selection while reducing process time by 30%.

Separates Mash into Wort and Spent Grains

The Nessie Continuous Mash Filtration System by Ziemann Holvrieka redefines mash processing with an innovative cascade filter unit arrangement, utilizing rotary disk filters to efficiently separate wort from spent grains. Designed for breweries and distilleries, it offers unprecedented flexibility in ingredient selection, making it suitable for an extensive range of products including craft beer, whiskey, and plant-based dairy alternatives. The system operates continuously, significantly reducing processing time by up to 30% while enhancing wort quality with up to 40% fewer polyphenols. Integration into your production line is seamless, supported by turbulent counterflow extraction technology that maximizes yield and maintains high product quality. Capable of achieving a first wort concentration of up to 32°P, the Nessie system empowers brewers with increased process variability and creativity, ideal for producing diverse beer and distillate styles. Its design promises energy efficiency and ease of use, supporting sustainable operation with reduced cleaning requirements. The robust construction in stainless steel ensures durability and corrosion resistance for challenging environments. Ziemann Holvrieka provides customization and technical support for tailored solutions, ensuring the equipment aligns perfectly with your production demands.

Benefits

- Increases production efficiency by reducing process time by up to 30%.

- Enhances product quality with up to 40% fewer polyphenols, preserving desired flavors.

- Offers cost advantages with higher grain yields and alternative starch sourcing.

- Allows for diverse product creation with decoupling of wort streams and a 32°P first wort concentration.

- Integrates easily with existing systems, optimizing operations and flexibility.

- Applications

- Chemicals, Hard seltzer, Beyond-beer beverages, Dairy, Beer, Juice, Edible oil, New food, Distilled beverages

- End products

- Craft beer, Flavored alcoholic beverages, Sunflower oil, Apple juice, Whiskey, Industrial-grade ethanol, Vodka, Hard seltzer flavors, Orange juice, Soy milk, Food-grade ethanol, Lactose-free milk, Plant-based dairy alternatives, Canola oil, Gin

- Steps before

- Milling, Mashing

- Steps after

- Fermentation, Beer Processing, Distillation, Packaging

- Input ingredients

- mash, cereals, starch sources, water

- Output ingredients

- wort, spent grains, extract

- Market info

- Ziemann Holvrieka is known for its expertise in providing industrial engineered-to-order equipment for breweries. They design and manufacture advanced brewing systems and solutions, earning a strong reputation for quality and innovation in the brewing industry.

- Filtration type

- Rotary disk filters

- Contact time

- Short

- Process time reduction

- Up to 30%

- First wort concentration

- Up to 32°P

- Filter units

- Four in cascade arrangement

- Extraction method

- Turbulent counterflow

- Sparging method

- Water injected through fine nozzles

- Working mechanism

- Continuous mash filtration

- Integrated steps

- Separation, sparging, filtration

- Automation level

- Automated dynamic process

- Batch vs. continuous operation

- Inline Continuous

- CIP/SIP

- CIP-Compatible

- Changeover time

- Reduced due to continuous operation

- Energy efficiency

- Optimized through shorter process time

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact design

- Filter units

- Four filter units in cascade arrangement

- Filter type

- Rotary disk filters

- Shape and size

- Cascade arrangement

- Feed method

- Turbulent counterflow extraction

- Discharge method

- Separated wort and spent grains

- Control panel type

- Touchscreen HMI / Button interface

- Integration

- SCADA / PLC integration

- Filtration system configuration

- Cascade arrangement

- Sparging method

- Turbulent counterflow extraction

- Raw material compatibility

- Various cereals and starch sources

- Wort stream capability

- Decoupling for optimization

- Batch flexibility

- Small batch brewing capability