Aseptic processing system for food products

Streamline your food processing line with an efficient aseptic processing system that ensures product safety and extends shelf life without chemical additives. Whether handling high-speed continuous operations or diverse product types, this compact solution simplifies integration while maintaining rigorous quality standards.

Processes and Fills Aseptic Food and Beverage Products

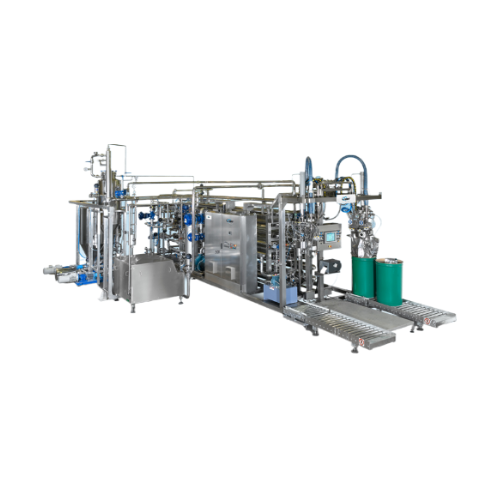

The READYGo Aseptic Monoblock from JBT FoodTech is designed for food and beverage producers needing aseptic processing and filling solutions. This system excels with its compact design, integrating all components onto a single stainless steel mainframe for easy installation and minimal space requirements. It is equipped to handle a diverse range of products, including fruit purees, tomato pastes, and juices, with capacities ranging from 500 to 6000 kg/h.

Harnessing the power of PLC-controlled operations, the READYGo Monoblock ensures high production speeds and operational efficiency while maintaining aseptic conditions throughout the process. Its fully integrated system requires only utility connections for power, water, air, and steam. Uniquely, the aseptic filling chamber can be opened without compromising sterility, offering flexibility in operation.

The equipment supports clean operation by eliminating the need for chemicals or sterile gases. It complies with industry standards for food safety, making it a reliable choice for processing apple puree, mango puree, almond milk, and other delicacies. With several feed tank options available, it adapts to various packing standards effortlessly, facilitating a seamless production line integration.

Benefits

- Enhances product shelf life without preservatives due to aseptic processing.

- Streamlines production with quick installation and minimal utility connections.

- Offers versatility for various packaging formats, reducing changeover times.

- Increases operational efficiency with fully PLC-controlled high-speed operations.

- Maintains sterility during operations, allowing flexible access to the filling chamber.

- Applications

- Beverages, Soups, Sauces, Fruit purees, Oils, Fruits, Nuts, Dressings, Tomato products, Seasonings, Juices, Vegetable purees

- End products

- Ketchup, Vegetable broth, Fruit smoothies, Almond milk, Apple puree, Carrot puree, Salad dressings, Nut oils, Mango puree, Tomato paste, Orange juice concentrate, Tomato sauce

- Steps before

- Preparation, Grinding, Mixing

- Steps after

- Sterilization, Packing, Labeling

- Input ingredients

- fruit purees with or without pieces, concentrated fruit purees, tomato-based non-concentrated products, tomato products concentrated or semi-concentrated, tomato and fruit dices, vegetable purees, clear or cloudy juices, natural or concentrated products

- Output ingredients

- aseptic fruit purees, aseptic tomato products, aseptic vegetable purees, aseptic juices, formulated aseptic products

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Capacity

- 500 to 6000 kg/h

- Automation

- PLC-controlled

- Installation

- Quick and easy

- Flexibility

- High

- Feed tank options

- Several available

- Chemicals used

- No chemicals or sterile gases

- Automation level

- Fully PLC-controlled

- Installation

- Quick and easy

- Flexibility

- High flexibility and simplicity

- Batch vs. continuous operation

- Inline continuous

- Cleaning method

- No chemicals or sterile gases used

- Cleanability

- High

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Biological compatibility

- Food-grade components

- Compact Footprint

- Designed for small/medium-sized spaces

- Mainframe Material

- Stainless Steel

- Single Frame Construction

- All components installed on one frame

- Installation Requirements

- Quick and easy installation, single utility connection

- Piping,Electrical Connections

- Pre-installed and factory-tested

- Control panel type

- PLC-controlled

- Compact footprint

- Yes