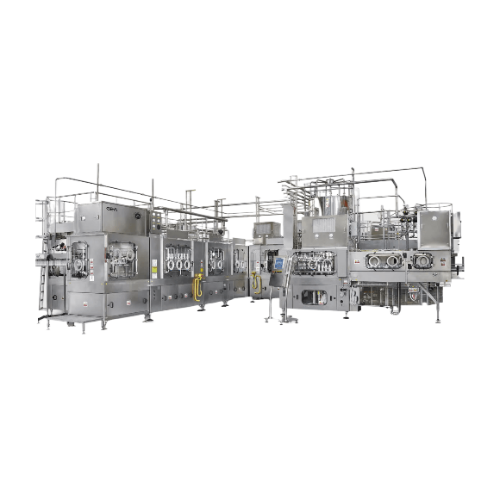

Advanced aseptic filling system for beverage bottles

Seeking a sterilization and filling system that maximizes sterilization efficiency and minimizes resource consumption? Discover the solution for aseptic handling of high and low acid beverages, ensuring up to 216 hours of continuous operation without intermediate cycles.

Sterilizes, Fills, and Caps Beverages in Containers

The ECOSpin2 Zero from GEA is an aseptic filling system that addresses the needs of beverage manufacturers, dairy producers, and food processors dealing with both high and low acid products. This system combines a rotary sterilizer, filler, and capper within a microbiological isolator to ensure contamination-free bottling. What sets the ECOSpin2 Zero apart is its ability to maintain continuous operation for 216 hours without intermediate sterilization protocols, thanks to its FDA-validated peracetic acid-based sterilization treatment.

It is suitable for a variety of applications, including fruit juices, carbonated soft drinks, yogurt drinks, and more, with a capacity of up to 72,000 bottles per hour for 500 ml bottles. The system is PLC-controlled and boasts resource efficiency, using 91% less water than previous models and ensuring zero emissions with minimal energy consumption. The external sterilization process accommodates diverse bottle shapes, making it highly adaptable to different production requirements.

ECOSpin2 Zero complies with stringent FDA regulations, maintaining a residual peroxide level below 0.5 ppm. The system’s design, featuring a non-valve sterilizer, simplifies maintenance and reduces wear. For enhanced productivity, it integrates with existing production lines, offering a flexible bottle feed and an efficient cap sterilization process. Customization is supported by GEA, allowing the system to adapt to specific operational needs.

Benefits

- Extends production runs to 216 hours without intermediate cleaning, maximizing operational efficiency.

- Cuts water usage by up to 91%, aligning with sustainability goals.

- Maintains aseptic conditions continuously, minimizing contamination risks and preserving product integrity.

- Simplifies maintenance with a no-valve design, reducing downtime and operational costs.

- Adapts to diverse bottle shapes, enhancing flexibility in product offerings and reducing changeover times.

- Applications

- Plastic bottles, Milk-based drinks, Sensitive beverages, Pet containers, High acid beverages, Low acid beverages, Hdpe containers

- End products

- Smoothies, Bottled water, Flavored milk, Iced tea, Cold brew coffee, Nutritional shakes, Yogurt drinks, Energy drinks, Carbonated soft drinks, Fruit juices

- Steps before

- Bottle Blow Molding, Bottle Depalletizing, Bottle Conveyance

- Steps after

- Capping, Labeling, Packing, Palletizing

- Input ingredients

- high acid beverages, low acid beverages, PET bottles, one-piece caps, gamma-ray pre-irradiated bags of caps, sterile water, peracetic acid solution

- Output ingredients

- sterilized bottles, sterilized caps, aseptic packaged beverages

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Production Speed

- 72, 000 bottles per hour

- Line Availability

- 216 hours

- Beverage Type Compatibility

- High Acid (HA) / Low Acid (LA)

- Bottle Sterilization Method

- PAA-based sterilization

- Cap Sterilization Method

- Spiral routing in PAA solution

- Residual Peroxide Level

- Less than 0.5 ppm

- Energy Consumption

- Lowest peracetic acid, water, and energy consumption

- Sterile Water Rinsing Unit

- Up to 91% water saving

- B. Atrophaeus Reduction

- Up to 6 log

- Rinsing Temperature

- Ambient temperature

- Environment Sterilization

- Zero peroxide emissions

- Spraying System Efficiency

- High-efficiency, rapid spraying

- Water Saving (Service Upgrades)

- Up to 83% water saving

- Working Mechanism

- Rotary sterilizer, filler, and capper enclosed in a microbiological isolator

- Integrated Steps

- Sterilization, filling, capping

- CIP/SIP

- No intermediate SOP cycles needed for 216 hours

- Automation Level

- FDA-validated technology

- Batch vs. Continuous Operation

- Continuous (216 hours without intermediate SOP)

- Cleaning Method

- PAA based sterilization

- Energy Efficiency

- Reduced energy consumption

- Environmental Impact

- Zero peroxide emissions, sustainability focus

- Biological compatibility

- Suitable for HA and LA beverages

- Corrosive resistance (e.g. acids)

- Designed to handle peracetic acid

- Cleanability

- Easy clean design with no-valve sterilizer

- Density/particle size

- Handles PET bottles of various sizes

- Container type

- PET Bottles

- FDA compliance

- Yes

- FDA materials

- Yes

- Compact footprint

- Reduced footprint

- One dedicated ancillaries skid

- Machine footprint

- Space-saving design

- Control panel type

- PLC-controlled

- Integrated system components

- Rotary sterilizer, filler, capper enclosed in isolator

- Discharge method

- Integrated blow-fill system

- Control panel type

- PLC / HMI

- Integration possibilities

- PLC / SCADA / ERP

- Cap and bottle compatibility

- Various shapes and sizes of PET bottles including those with handles

- Sterilization options

- Peracetic acid (PAA) for both high and low acid beverages

- Nozzle design

- Clogging-free penetrating nozzle (full-cone or blade shape)

- Water rinsing unit

- Advanced nozzle design for reduced water consumption

- Cap sterilization option

- Sterilcap IM and Sterilibag systems

- Automatic sensor calibration

- Smart Sensor for nozzle efficiency verification