Compact bottling line for water

Revolutionize your bottling process with a compact solution that integrates multiple operations into a single coordinated unit, significantly reducing space, energy consumption, and total cost of ownership.

Streamlines Bottling and Packaging Operations

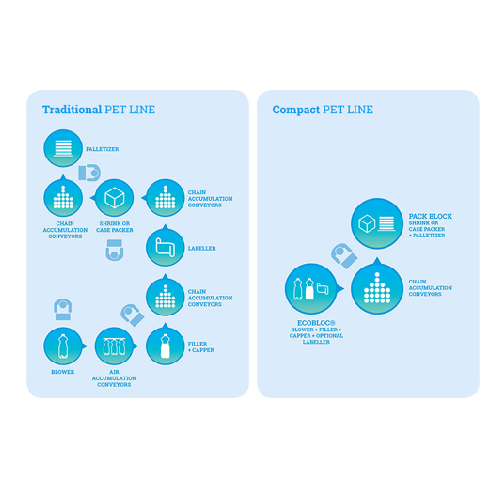

The ECOBLOC® and PACKBLOC from SMI Group are integrated systems designed for seamless operation in beverage production and bottling plants. By combining stretch-blowing, filling, capping, and packaging into two highly efficient units, these systems minimize space and reduce energy consumption through optimized motor control. Suitable for producing PET and rPET bottles for water, juices, and carbonated drinks, the ECOBLOC® simplifies production by combining multiple processes into one compact machine. The PACKBLOC handles secondary packaging and palletizing with its Cartesian-axis palletizer, ensuring smooth downstream operations. Capable of producing up to 14,000 bottles per hour, these systems support high-speed, continuous operations while reducing labor and maintenance costs, making them ideal for large-scale beverage manufacturers and packaging companies. Integration with existing production lines is facilitated through advanced automation, promoting minimal downtime and operational efficiency. Additionally, the system offers customizable labeling options and adheres to industry standards for food and beverage safety.

Benefits

- Reduces operational costs by integrating multiple functions into a compact system.

- Minimizes energy usage with high-efficiency motors, cutting power consumption significantly.

- Lowers labor requirements through multifunctional automation, reducing the need for multiple operators.

- Decreases maintenance frequency with streamlined design, leading to fewer spare part needs.

- Optimizes floor space utilization in production facilities, accommodating high-capacity operations.

- Applications

- Bottled water, Rpet bottling, Liquid packaging, Pet bottling, Beverage production

- End products

- Flat water bottles, Mineral water bottles, Rpet water bottles, Rpet soda bottles, Pet water bottles, Rpet juice bottles, Functional beverage bottles, Carbonated drink bottles, Juice bottles, Pet beverage bottles

- Steps before

- Material Preparation, Preform Heating

- Steps after

- Labelling, Secondary Packaging, Palletizing, Distribution

- Input ingredients

- PET bottles, rPET bottles, water, energy

- Output ingredients

- filled bottles, capped bottles, labeled bottles, packaged bottles, palletized bottles

- Market info

- SMI Group is known for designing and manufacturing innovative packaging machinery and bottling plants. They provide cutting-edge solutions for ETO equipment, emphasizing flexibility, reliability, and efficiency in serving industries like food, beverage, and consumer goods.

- Production Speed

- 14, 000 bottles per hour (bph)

- Bottle Capacity

- 0.33L / 0.5L / 1.5L

- Integration Level

- High

- Space Requirement

- Reduced

- Energy Efficiency

- High-efficiency motors

- Automation Level

- High

- Conveyor Belt Length

- Reduced

- Machine Units

- Two

- Maintenance Requirement

- Low

- Personnel Requirement

- Reduced number of operators

- Automation level

- Manual / PLC

- Integration of operations

- Blowing, Filling, Capping

- Efficiency

- Energy saving features

- Changeover time

- Reduced inline operations

- Space efficiency

- Compact footprint

- System blocks

- Two-block system (ECOBLOC®, PACKBLOC)

- Maintenance requirements

- Reduced interventions

- TCO reduction

- Lower initial investment

- Operator requirement

- Single operator capable

- Cleaning method

- CIP

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Discharge method

- Integrated automatic palletizer

- Control panel type

- User-friendly interface

- Integration possibilities

- Smart Factory 4.0

- Control and monitoring

- SWM line supervisor

- Secondary packaging options

- Shrink film, stretch film, wrap-around cardboard