Efficient mash agitator for breweries

Enhance your mashing process with an agitator designed to optimize heat transfer and promote uniform mixing, ensuring consistent quality across a wide range of viscosities and concentrations.

Enhances Mixing and Heat Transfer

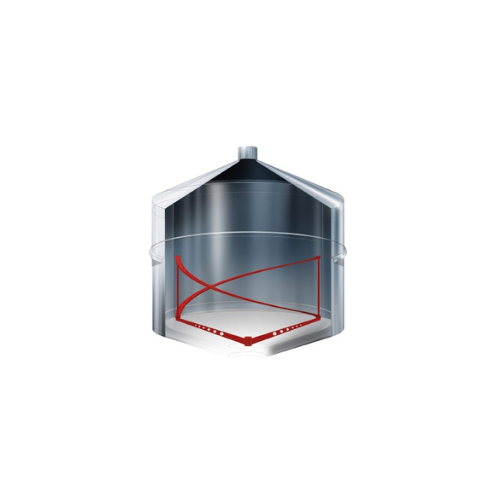

The Mash Tun COLIBRI, offered by Ziemann Holvrieka, features a revolutionary agitator design that significantly enhances mashing processes across multiple industries, including brewing, food processing, and beverage production. The unique wing-like profile of its helix agitator blades optimizes mixing and heat transfer, crucial for achieving high enzymatic conversion rates and efficient use of raw materials.

This equipment is capable of handling various applications such as beer wort creation, plant-based milk processing, and more. The Mash Tun COLIBRI seamlessly integrates into high-speed, continuous production lines, maintaining uniform temperature and concentration distribution within the mash.

Its design incorporates perforated agitator bars positioned above the heating zone, ensuring consistent flow and minimizing mash “burning,” which can enhance the quality of end products like fruit juice concentrates and flavored carbonated water beverages. The self-cleaning effect across all heating zones reduces maintenance downtime, while the option for customization ensures the equipment meets specific processing needs.

Benefits

- Increases enzymatic conversion rates, enhancing product yield.

- Shortens mashing times, boosting overall production efficiency.

- Reduces energy costs through optimized heat transfer.

- Minimizes raw material waste with efficient mixing.

- Ensures product consistency with uniform temperature and concentration distribution.

- Applications

- Chemicals, Distilling, Beyond-beer beverages, Hard seltzer, Beer, Juice, Edible oil, New food, Dairy

- End products

- Fruit juice concentrates, Alternative grain-based alcoholic beverages, Beer wort, Sunflower oil, Ethanol, Cheese whey, Flavored carbonated water beverages, Chemical solvents, Plant-based milk

- Steps before

- Milling, Mixing, Heating, Hydration

- Steps after

- Fermentation, Filtration, Lautering, Cooling

- Input ingredients

- raw materials, mash, water, starch sources

- Output ingredients

- converted mash, beer

- Market info

- Ziemann Holvrieka is known for its expertise in providing industrial engineered-to-order equipment for breweries. They design and manufacture advanced brewing systems and solutions, earning a strong reputation for quality and innovation in the brewing industry.

- Heat transfer efficiency

- High

- Enzymatic conversion rate

- Highest

- Mashing time

- Shorter

- Shear force

- Minimal

- Homogeneity of mix

- Uniform distribution

- Self-cleaning effect

- Yes

- Profile of agitator blades

- Wing-like

- Agitator bar design

- Perforated

- Heat transfer efficiency

- High

- Mash distribution

- Homogeneous

- Agitator shear forces

- Low

- Cleaning method

- Self-cleaning

- Batch vs. continuous operation

- Batch

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Shear force control

- Low

- Agitator blade profile

- Wing-like helix

- Agitator bars

- Perforated above bottom heating zone

- Bracings

- Alternating inclined transverse

- Homogenisation

- Enhanced by transverse bracings

- Agitator blade type

- Wing-like profile of the helix agitator blades

- Agitator bar configuration

- Perforated agitator bars above the bottom heating zone

- Bracing design

- Alternating inclined transverse bracings

- Cleaning mechanism

- Self-cleaning effect on all heating zones