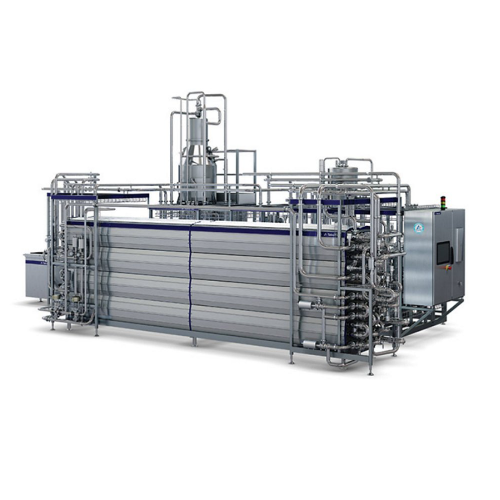

Indirect Uht processing for dairy products

Enhance your dairy and beverage operations with state-of-the-art ultra-high temperature treatment, ensuring extended shelf life and optimal flavor retention in aseptic conditions.

Processes Liquid Products via Aseptic UHT Treatment

The Tetra Pak® Indirect UHT unit DE delivers exceptional aseptic processing capabilities for dairy and beverage industries, enabling efficient ultra-high temperature treatments. This unit employs a tubular or plate heat exchanger for indirect heating, ensuring safe and shelf-stable products. With capacities ranging from 1,000 to 40,000 l/h, it’s ideal for processing various liquid products such as UHT milk, flavored milk, creams, and plant-based beverages. The system boasts intelligent control features like IntelliCIP™ 2.0, optimizing cleaning processes for more uptime and reduced utility consumption. Energy savings are achieved through product-to-product heat regeneration, cutting steam usage significantly. The unit’s design minimizes fouling, allowing for extended run times and reduced production costs. Fully automated operation integrates seamlessly into existing production lines, ensuring continuous, high-efficiency output while maintaining product quality and safety.

Benefits

- Maximizes operational uptime with minimized fouling and extended run times.

- Enhances energy efficiency with 92% heat recovery through product-to-product regeneration.

- Reduces utility consumption with on-demand cleaning optimized by IntelliCIP™ technology.

- Minimizes product losses with innovative bottom-filling balance tank design.

- Optimizes hygiene and safety with fully automated cleaning-in-place (CIP) systems.

- Applications

- Cream, Buffalo milk, Formulated dairy products, Coffee, Yoghurt drinks, Soy milk, Flavoured milk, Juice, Tea, Dairy products

- End products

- Cappuccino, Uht milk, Peach-flavored yoghurt drink, Cold brew coffee, Orange juice, Buffalo mozzarella milk, Soy-based infant formula, Whipping cream, Chocolate milk, Chamomile tea

- Steps before

- Milk collection, Homogenization, Mixing, Pre-heating

- Steps after

- Cooling, Aseptic storage, Filling, Packaging

- Input ingredients

- milk, flavoured milk, cream, yoghurt drinks, buffalo milk, formulated dairy products, soy milk, juice, tea, coffee

- Output ingredients

- UHT treated dairy products, ambient temperature stable products, aseptic packaged products, processed milk, processed cream, processed yoghurt drinks

- Market info

- Tetra Pak is renowned for providing innovative packaging solutions, specializing in carton packaging for the food and beverage industry. It is esteemed for high-quality, sustainable, and efficient processing and packaging equipment on a global scale.

- Capacity

- 1, 000 – 40, 000 l/h

- Heat recovery

- 92%

- Steam consumption

- 20 kg/1000 kg of product

- Operating time

- Up to 40 hours

- Outlet temperature rise

- ~15 °C above inlet

- Energy savings with protective panels

- Up to 11%

- Cooling medium reduction

- Drastic reduction

- CIP technology

- IntelliCIP™ 2.0

- Hibernation mode energy savings

- Up to 85%

- Automation level

- PLC / SCADA

- Batch vs. continuous operation

- Inline Continuous

- CIP/SIP

- Automatic CIP

- Changeover time

- Minimized due to bottom-filling balance tank

- Cleaning method

- CIP Adaptive with IntelliCIP™ 2.0

- Energy efficiency

- High, with 92% heat recovery

- Fouling control

- Temperature-controlled, optimized setup

- Hibernation mode

- Automatic to reduce energy consumption

- Product-to-product regeneration

- Yes, direct regeneration

- Abrasion resistance

- Yes

- Biological compatibility

- Yes

- Cleanability

- CIP/SIP compatible

- Corrosive resistance (e.g. acids)

- High

- Density/particle size

- 0.5–2.5 g/cm³

- Heat exchanger protective panels

- Energy savings potential

- Heat exchanger floating protection system

- Thermal expansion flexibility