Innovative beer filling and capping technology

Revolutionize your filling process with an integrated system that combines filling and capping in one unit, reducing time and space requirements while ensuring product quality—perfect for high-speed beverage production with precise temperature control and reduced CO2 consumption.

Combines Filling and Capping in One Fast Process

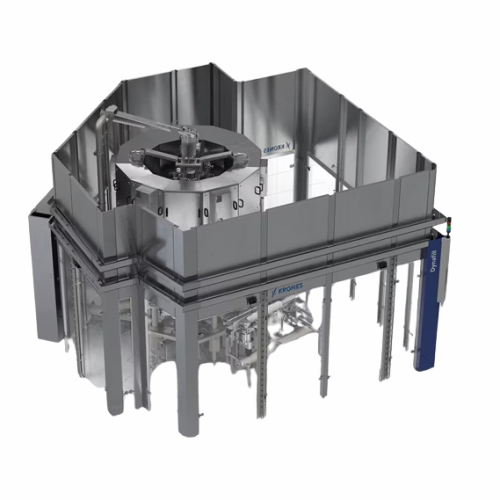

The Krones Dynafill revolutionizes the filling and capping process by integrating both tasks into a single high-speed operation, achieving unmatched efficiency and precision. Designed for beverages from beer to milk and spirits, it fills and seals containers in under five seconds at speeds of up to 80,000 units per hour. Its innovative design minimizes energy consumption and reduces the machine footprint by 50%, allowing seamless integration into your existing line. The Dynafill operates at up to 30°C, making it suitable for both cold and warm filling applications. This closed system ensures product purity by preventing contamination, and the decentralized power supply benefits maintenance with user-friendly access. With reduced CO2 usage by 20% and integration into a CIP circuit, the Dynafill promises a sustainable and clean operation. Whether working on a new establishment or upgrading a current setup, its space-efficient design offers significant layout flexibility. Configurable and tested under diverse conditions, it’s backed by Krones’ engineering expertise, ensuring optimal performance for your beverage production needs.

Benefits

- Enhances operational efficiency by filling and capping in just five seconds.

- Achieves higher production output with a 50% smaller footprint.

- Lowers energy and CO2 consumption, supporting sustainability goals.

- Preserves product purity with a closed, contamination-free system.

- Increases line design flexibility for both new and existing facilities.

- Applications

- Water, Milk and milk-based drinks, Spirits, Juice, Soft drinks, Beer

- End products

- Pilsner, Bottled water, Lager, Grape juice, Stout, Whole milk, Mineral water, Craft beer, Orange juice, Almond milk, Rum, Sparkling water, Cola, Chocolate milk, Vodka, Apple juice, Whiskey, Soy milk, Ginger ale, Root beer, Lemonade, Skim milk, Brandy, Ale, Gin

- Steps before

- Bottle washing, Conveyor setup

- Steps after

- Labelling, Packing, Palletising

- Input ingredients

- beer, beverage containers, bottles, caps

- Output ingredients

- filled bottles, capped bottles

- Market info

- Krones is renowned for its expertise in manufacturing beverage and liquid food processing and packaging equipment, offering comprehensive solutions that include filling, packaging technology, and processing systems, and is reputed for innovation and quality in the industry.

- Filling Speed

- 80, 000 containers per hour

- Filling Temperature

- Up to 30°C

- Filling and Capping Time

- Less than 5 seconds

- Filling Valve Number

- 66 valves

- Footprint Reduction

- 50 percent

- Container Type

- PET / Glass

- CO2 Consumption

- 20 percent lower than conventional systems

- Power Integration

- Decentralised electronics

- Capping Type

- Standard and twist-off crowns

- Automation Type

- Servo capper

- Combined filling and capping process

- Single machine

- Automation level

- Integrated PLC

- Changeover time

- Minimal

- CIP/SIP

- Closed system CIP

- Batch vs. continuous operation

- Continuous

- Energy efficiency

- Reduced energy requirement

- Cleaning method

- CIP

- Filling speed

- 80, 000 containers per hour

- Filling temperature

- Up to 30°C

- Footprint reduction

- 50%

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container size

- 0.5 L to large containers

- Container type

- Glass / PET bottles

- Filling temperature

- Ambient temperatures up to 30 °C

- Machine footprint

- 50% smaller

- Compact footprint

- 50% reduced

- Filling and capping unit

- Single unit

- Number of filling valves

- 66 valves at 36, 000 containers/hr

- Filling speed

- 80, 000 containers/hr

- Filling process duration

- 0.5 seconds

- Footprint reduction

- 50%

- Compact footprint

- Reduced by 50%

- Control panel type

- Integrated control block in filling valve

- Integration possibilities

- Direct block-connection to labeller

- Maintenance features

- User-friendly dismantling device

- Changeover capabilities

- MultiGuide Base clamping starwheels

- Capping options

- Servo capper for standard and twist-off crowns

- Filling options

- Filling valve with diagonal movement

- Decentralized electronics

- Control block integrated in filling valve