Homogenizers for high-pressure applications

Achieve unparalleled product consistency and stability with precision-engineered high-pressure homogenizers, essential for ensuring uniform particle size distribution and enhancing emulsification in liquid processing across diverse applications.

Homogenizes and Emulsifies Liquids Efficiently

The HST high-pressure homogenizers offer robust solutions for industries requiring precise liquid processing, such as food, pharmaceuticals, and chemicals. Utilizing a narrow-gap homogenizing valve, these machines break down fat globules and agglomerates, ensuring uniform product consistency and extended shelf life. Models like the HST HL and HLI series serve applications from dairy to intravenous emulsions, processing between 300 to 80,000 liters per hour. Their aseptic design options and reduced water consumption features enhance efficiency and product safety. They are available in corrosion-resistant materials, supporting a wide range of process conditions. HST homogenizers also include noise insulation, energy-saving multi-gap valve options, and customized piston coatings to minimize maintenance needs. Designed for seamless integration, they support continuous operations and can be configured to specific production line requirements, ensuring compliance with industry standards.

Benefits

- Enhances product stability and shelf life through precise homogenization.

- Minimizes maintenance with durable, abrasion-resistant piston coatings.

- Offers energy efficiency with reduced water consumption designs.

- Aseptic options prevent contamination, crucial for sensitive applications.

- Customizable features enable seamless integration into existing production lines.

- Applications

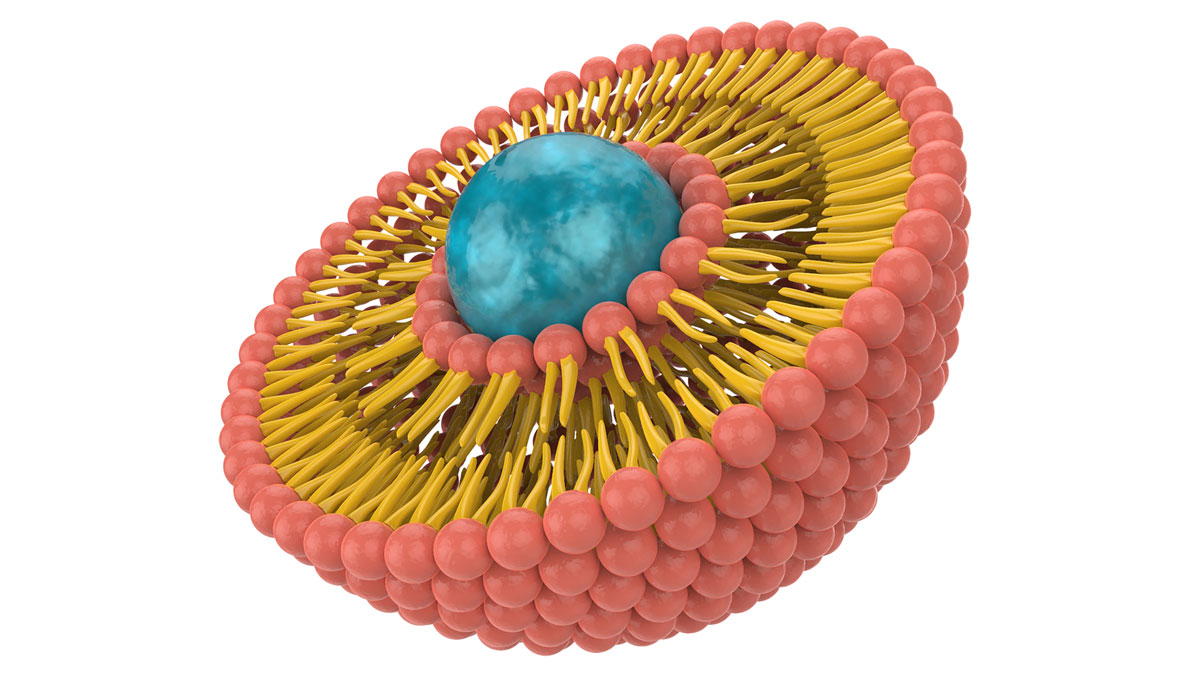

- Cream, Food industry, Baby and infant food, Ointments, Colours, Dyes, Uht milk, Ingredients, Insecticides, Textures, Cell disruption, Chemicals industry, Beauty creams, Mixed ice cream, Liposomes, Resin dispersions, Fruit juices, Latex, Fuels, Water emulsions, Nanosomes, Pigment dispersions, Pharmaceutical and cosmetics industry, Vegetable juices, Condensed milk, Egg products, Special drinks, Fresh milk, Ketchup, Intravenous emulsions, Yoghurt, Wax emulsions, Sauces and dressings, Lubricants, Herbicides

- End products

- Whipped cream, Sweetened condensed milk, Automotive lubricant, Liposomal delivery systems, Infant formula, Greek yogurt, Carrot juice, Liposomal vitamin c, Whole milk, Foundation texture base, Caesar dressing, Anti-aging cream, Corn herbicide, Epoxy resin, Orange juice, Energy drinks, Active cosmetic ingredients, Inkjet printer ink, Acne treatment ointment, Carnauba wax polish, Garden insecticide spray, Shelf-stable milk, Acrylic paint, Yeast cell disruption, Parenteral nutrition, Ice cream blend, Powdered egg whites, Blue textile dye, Natural latex gloves, Biodiesel blends, Water-based acrylic emulsions, Tomato ketchup

- Steps before

- Emulsification, Heat Treatment, Grinding

- Steps after

- Sterilization, Creaming Stability, Packing

- Input ingredients

- Fresh milk, Cream, Vegetable juices, UHT milk, Yoghurt, Baby and infant food, Condensed milk, Ketchup, Sauces and dressings, Mixed ice cream, Fruit juices, Egg products, Special drinks, Intravenous emulsions, Liposomes, Ingredients, Textures, Beauty creams, Dyes, Ointments, Cell disruption, Pigment dispersions, Lubricants, Fuels/water emulsions, Wax emulsions, Insecticides/herbicides, Resin dispersions, Nanosomes, Colours, Latex

- Output ingredients

- Stability, Colour intensity, Flavour, Consistency, Long shelf life, Creaming stability

- Market info

- HST Maschinenbau is known for its expertise in designing and manufacturing custom-engineered industrial machinery, particularly in the sectors of hydraulics and automation, with a strong reputation for quality and innovative solutions tailored to client needs.

- Capacity

- 5.5 - 250 kW (300 l/h until 35, 000 l/h)

- Capacity

- 55-90 kW (8, 000 - 14, 000 l/h) and 400 kW (up to 80, 000 l/h)

- Capacity

- 3-75 kW (10, 000 l/h – 200 bar)

- Design Options

- Aseptic design

- Design Options

- ATEX design

- Noise Insulation

- Noise insulation cladding

- Energy Efficiency

- Reduced water consumption in "Integrated" series

- Working Mechanism

- High-pressure homogenization

- Flow Type

- Turbulent and laminar flow

- Process Method

- Batch / Inline Continuous

- Pressure Range

- 300l/h until 35, 000l/h

- Energy Input

- Stability and consistency improvement

- Noise Control

- Noise insulation cladding

- Aseptic Design Option

- Yes

- ATEX Design Option

- Yes

- Piston Material Adaptability

- Chrome-plated, ceramic, HST coating

- Packing System

- Extended service life

- Aseptic Processing

- Post-heat treatment homogenization

- Pneumatic/Hydraulic Valve Control

- Yes

- Product Adaptability

- Customized according to application

- Abrasion resistance

- High-strength stainless steels, ceramic pistons

- Biological compatibility

- Aseptic design options

- Cleanability

- Hygienic design, CIP/SIP compatibility

- Corrosive resistance (e.g. acids)

- Special HST coating

- Density/particle size

- Adaptable piston materials

- Product stability

- Improved

- Particle size reduction

- Yes/No

- Homogenization consistency

- High

- Capacity range

- 5.5 - 250kW, 55-90kW, 3-75kW

- Capacity (volume)

- 300l/h until 35, 000l/h, 8, 000 - 14, 000l/h, up to 80, 000l/h

- Noise insulation

- Noise insulation cladding

- Aseptic design

- Aseptic design available

- ATEX design

- ATEX design available

- Machine series

- HLL0, HL 1, HL 2, HL 2.5, HL 3, HL 4, HL 5, HL 6, HLI 55, HLI 75, HLI 90, HLI 8, HLE 3, HLE 5.5, HLE 7.5, HLE 11, HLE 15, HLE 18.5, HLE 22, HLE 30, HLE 37, HLE 45, HLE 55, HLE 75

- Discharge method

- Pneumatic or hydraulic valve control

- Valve materials

- High-strength stainless steels, sintered materials, ceramics

- Piston materials

- Standard, chrome-plated, ceramic, special HST coating

- Product diversity adaptability

- Customizable for various product needs

- Valve material

- Stainless steel / Sintered / Ceramic

- Piston material

- Standard / Chrome-plated / Ceramic / Special coating

- Piston geometry

- Customized based on process parameters

- Packing system materials

- Various for extended service life

- Design options

- Aseptic / ATEX

- Homogenizing valve type

- PLUG / PILOTED / Multigap

- Valve control

- Pneumatic / Hydraulic