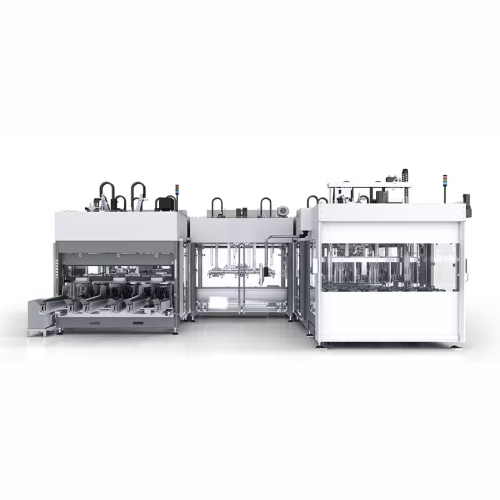

Flexible packaging line for beverage production

Streamline your beverage production with a flexible system capable of handling over 20 packaging combinations, ensuring seamless integration and high-speed operation for diverse product lines.

Handles Diverse Packaging Combinations Efficiently

The Krones Varioline offers a versatile solution for beverage, food, and packaging industries. This modular packaging line efficiently processes secondary and tertiary packaging, integrating seamlessly into an automated production setup. It uniquely combines multiple packaging technologies, from carton sleeves to multipacks, with a throughput of up to 100,000 containers per hour. The Varioline is characterized by its continuous container infeed, minimizing product stress with a synchronized gripper and container flow. Energy efficiency is achieved through servo-motor-controlled drives and an innovative braking energy recovery system, meeting IE4 efficiency standards. With options for ACOPOS multi drive systems and energy measurement tools, the Varioline optimizes energy usage and media efficiency. Engineered for easy integration, it supports various operations such as packing, sealing, and orientation. Built with sustainable practices, it uses lifetime-lubricated bearings and H1-greases, reducing maintenance. Suitable for products like carbonated soft drinks, flavored milk, and spirits, it can handle both solid and liquid types, supporting beverage producers in meeting diverse packaging demands with precision and reliability.

Benefits

- Maximizes operational flexibility with over 20 customizable packaging combinations.

- Reduces energy usage by leveraging servo-motor-controlled drives and energy recovery systems.

- Decreases product damage risk through continuous, pressure-free infeed systems.

- Streamlines maintenance with integrated, self-contained components and sustainable materials.

- Enhances production efficiency with high-speed capacity, processing up to 100,000 containers per hour.

- Applications

- Beverages, Water, Alternative proteins, Milk and milk-based drinks, Spirits, Plant-based milk alternatives, Juice, Soft drinks

- End products

- Lactose-free milk, Bottled water, Whiskey, Protein shakes, Vodka, Almond milk, Rum, Soy milk, Flavoured milk, Carbonated soft drinks, Fruit juices, Gin

- Steps before

- Carton erector, Container infeed, Packaging requirement definition

- Steps after

- Carton sealing, Labeling, Palletizing

- Input ingredients

- carton sleeves, trays, multipacks, glass containers, soft containers

- Output ingredients

- packaged beverages, secondary packaging, tertiary packaging, carton sleeves, trays, multipacks

- Market info

- Krones is renowned for its expertise in manufacturing beverage and liquid food processing and packaging equipment, offering comprehensive solutions that include filling, packaging technology, and processing systems, and is reputed for innovation and quality in the industry.

- Output Capacity

- Up to 100, 000 containers per hour

- Packaging Formats

- More than 20 combinations

- Module Variants

- Multipacks, Carton Sleeves, Trays, Universally Usable

- Container Infeed System

- Continuous, pressure-free

- Energy Efficiency Class

- IE4

- Servo-Motor-Controlled Drives

- Yes

- Energy Measurement

- Optional

- Media Efficiency

- Flow meter for compressed air, leakage detection

- Lubrication

- Enclosed lifetime-lubricated bearings

- Lubricants

- H1-greases

- Modular machine configuration

- Modular variant options

- Packaging type flexibility

- 20+ packaging combinations

- Container processing capability

- Non-returnable and returnable

- Output capacity

- Up to 100, 000 containers per hour

- Integration level

- Single source system

- Continuous container infeed

- Yes, reduces product stress

- Machine operation continuity

- No interface interruption

- Energy efficiency

- IE4 efficiency class drives

- Braking energy reuse

- Yes, in ACOPOS system

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Packaging combinations

- More than 20 types

- Modular machine configuration

- Three variants

- Output capacity

- Up to 100, 000 containers per hour

- Module types

- Multipacks / Carton sleeves and trays / Universal

- Storage capacity

- Up to 4.5 meters of magazine conveyors

- Component integration

- Conventional carton erector and sealer integrated

- Discharge method

- Continuous container infeed

- Module configuration

- Multipacks, carton sleeves, trays

- Modular concept variants

- Three variants available

- Integration possibilities

- Combination of six machines

- Packaging combinations

- More than 20 combinations

- Special functions module

- Orientation, sealing

- Gluing unit

- Optional

- Continuous container infeed

- Included