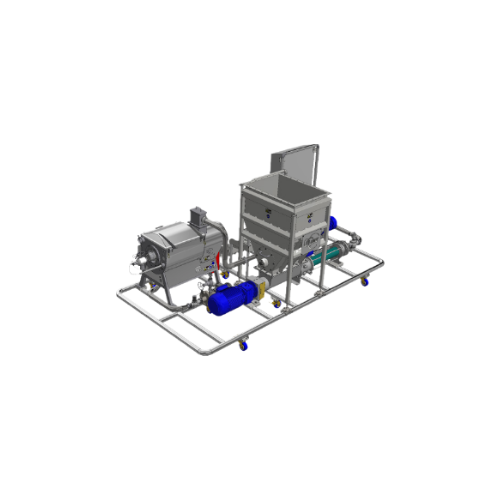

Vegetable and fruit processing skid

Optimize your fruit and vegetable processing with a compact skid that seamlessly integrates conveying, size reduction, and heating, streamlining your workflow for efficient juice and puree production.

Processes and Pumps Fruits and Vegetables Efficiently

The READYGo™ Vegetable/Fruit Processing Skid from JBT is a versatile and compact solution designed for the seamless integration of conveying, size reduction, heating, and pumping processes within a single skid. This equipment is ideal for fruit and vegetable processors, juice manufacturers, and beverage producers aiming to produce products like tomato paste, mango puree, and carrot juice with ease. Utilizing a continuous processing flow, it supports efficient throughput, ensuring high-capacity operations with minimal manual intervention. The skid’s stainless steel construction and food-grade polymer surfaces ensure compliance with hygiene standards, while its Clean-in-Place capability simplifies maintenance. Equipped with a control panel featuring variable frequency drives for precise speed control, the skid allows for easy electrical integration and operational flexibility. Optional mounting on casters adds mobility for versatile plant layout arrangements. Additionally, it can be configured with JBT’s FTE turbo extractor for enhanced production of viscous juices and purees, tailored to your specific production needs.

Benefits

- Enhances production efficiency by integrating multiple processing steps on a compact skid.

- Reduces cleaning time and risk of contamination with its hygienic design and Clean-in-Place capability.

- Optimizes operational flexibility through variable frequency drives for precise process control.

- Increases mobility and versatility with optional caster mounting for adaptable facility layouts.

- Supports high-quality juice and puree production using the optional turbo extractor configuration.

- Applications

- Beverages, Fruits, Vegetables, Purees, Juices

- End products

- Apple juice, Orange juice, Vegetable smoothies, Berry puree, Mango puree, Carrot juice, Tomato paste, Strawberry puree

- Steps before

- Conveying, Size Reduction, Heating Operations

- Steps after

- Juice Pumping, Viscous Juices and Purees Production, Downstream Processes

- Input ingredients

- vegetables, fruits

- Output ingredients

- juices, purees, smoothies

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Material

- Stainless steel, food-grade polymer

- Processing Type

- Continuous

- Automation

- Control panel with variable frequency drives

- Cleanability

- Capable of Clean-in-Place (CIP)

- Mobility

- Optionally mounted on casters

- Pump Type

- Integrated hygienic product pump

- Data System

- Preconfigured for iOPS data system

- Working mechanism

- Continuous processing

- Integrated steps

- Conveying, size reduction, heating

- Automation level

- PLC / Variable frequency drive control

- CIP/SIP

- Capable of Clean-in-Place

- Batch vs. continuous operation

- Inline Continuous

- Mobility

- Optionally mounted on casters

- Hygienic materials

- Stainless steel, food-grade polymers

- Corrosion resistance

- Stainless steel

- Cleanability

- Designed for Clean-in-Place (CIP) systems

- Abrasion resistance

- Stainless steel construction

- Compact footprint

- Yes

- Frame material

- Stainless steel

- Mobility

- Casters for easy movement

- Customization Options

- FTE turbo extractor integration

- Frame design

- Compact skid

- Control panel type

- Variable frequency drives

- Discharge method

- Integrated hygienic product pump

- Control panel type

- Variable frequency drives

- Mobility

- Optionally mounted on casters