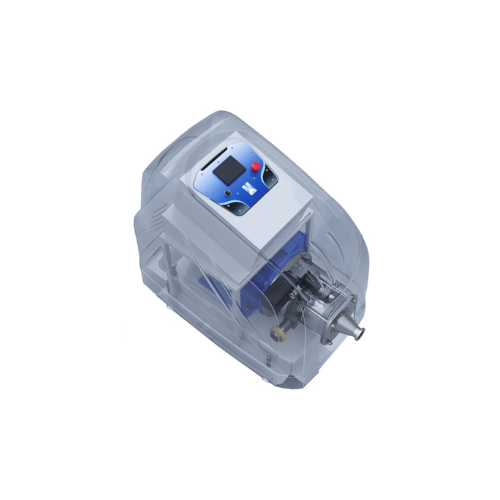

Colloidal mill for industrial homogenization

Achieve consistent emulsification, size reduction, and uniform particle distribution for complex mixtures with this high-speed colloidal mill, essential for producing smooth sauces, advanced nano suspensions, and stable pharmaceutical preparations in continuous processing environments.

Processes and Homogenizes Liquid and Slurry Products

The Colloidal Mills – Model BMC from Bertoli, part of the Interpump Group S.p.A., is engineered for industries that require precise homogenization and grinding processes, such as food and beverage, pharmaceuticals, and cosmetics. This model uses a robust rotor-stator mechanism, ensuring consistent particle size distribution for products like nanoparticle suspensions and cosmetic creams. With a capacity of 13,000 liters per hour and 37 kW power, it operates efficiently under pressures up to 6 bar. The Siemens KTP 400 PLC automation system allows seamless integration into production lines, supporting continuous, high-speed operations. Constructed with AISI 630 stainless steel for superior wear resistance, it features a tungsten carbide mechanical seal for enhanced durability. The model includes a cooling system that improves operation sustainability and noise levels below 85 dBa for a safer working environment. Designed for easy cleaning and maintenance, its modular configuration offers customization options to fit specific industrial requirements, ensuring compliance with rigorous process standards.

Benefits

- Ensures uniform product consistency, enhancing product quality across diverse applications.

- Increases production efficiency with capacities up to 13,000 liters per hour.

- Reduces operational noise, providing a safer work environment below 85 dBa.

- Offers easy integration with PLC-controlled automation, minimizing manual intervention.

- Enhances material durability and performance with corrosion-resistant stainless steel construction.

- Applications

- Pharma and biotech, Cosmetic, Chemical and nano dispersion, Food and beverage, Dairy

- End products

- Cosmetic creams, Pharmaceutical suspensions, Milk homogenization, Biotechnology enzyme preparations, Nanoparticle suspensions, Sauce emulsions, Fruit juices

- Steps before

- Grinding, Emulsification, Blending, Pre-mixing

- Steps after

- Homogenization, Filling, Cooling, Quality Control

- Input ingredients

- dairy, food and beverage, chemical and nano dispersion, pharma and biotech, cosmetic

- Output ingredients

- homogenized dairy products, blended food and beverage, nanodispersions, pharmaceutical mixtures, cosmetic emulsions

- Market info

- Bertoli, part of the Interpump Group, is known for its expertise in designing and manufacturing high-pressure homogenizers and positive displacement pumps, serving industries like food processing, pharmaceuticals, and cosmetics, with a reputation for reliability and innovation.

- Power

- 37 kW

- Pressure

- 6 bar

- Capacity

- 13, 000 l/h

- Poles

- 2

- Machine weight

- 600 kg

- Product inlet

- Øe65

- Product discharge

- Øe65

- Cooling water inlet

- 1/2″

- Cooling water discharge

- 1/2″

- Noise level

- < 85 dBa

- Electric motor

- 220/380/440V.50/60Hz 2 poles

- Automation system

- PLC, Siemens KTP 400

- Power

- 37 kW

- Pressure

- 6 bar

- Capacity

- 13, 000 l/h

- Noise level

- < 85dBa

- Automation level

- PLC, Siemens KTP 400

- Cooling method

- Cooling mechanical seal made in tungsten carbide

- Material of construction

- AISI 630, Stainless steel rotor and stator

- Voltage

- 220/380/440V.50/60Hz

- Abrasion Resistance

- High

- Corrosive Resistance (e.g. acids)

- Stainless Steel AISI 630

- Biological Compatibility

- Yes, for Food and Pharma applications

- Cleanability

- Easy CIP/SIP integration

- Density/Particle Size

- Suitable for varied densities/particle sizes

- Machine weight

- 600 kg

- Product inlet size

- Øe65

- Product discharge size

- Øe65

- Cooling water inlet

- 1/2″

- Cooling water discharge

- 1/2″

- Machine power

- 37 kW

- Capacity

- 13, 000 l/h

- Noise level

- , lt

- 85dBa

- Cooling mechanical seal

- Tungsten carbide

- Control panel type

- PLC, Siemens KTP 400

- Discharge method

- Flange and counterflange inlet and outlet product

- Capacity

- 13, 000 l/h

- Power

- 37 kW

- Pressure

- 6 bar

- Material

- Stainless steel rotor and stator (AISI 630), Tungstene carbide mechanical seal

- Electric motor specification

- 220/380/440V.50/60Hz 2 poles

- Noise level

- , lt

- 85dBa