High-pressure homogenizers for dairy and beverage industries

Achieve precise emulsion stability and consistent particle distribution with high-pressure homogenizers, ideal for enhancing product uniformity and extending shelf life in demanding liquid processing applications.

Breaks Down Particles and Homogenizes Liquids

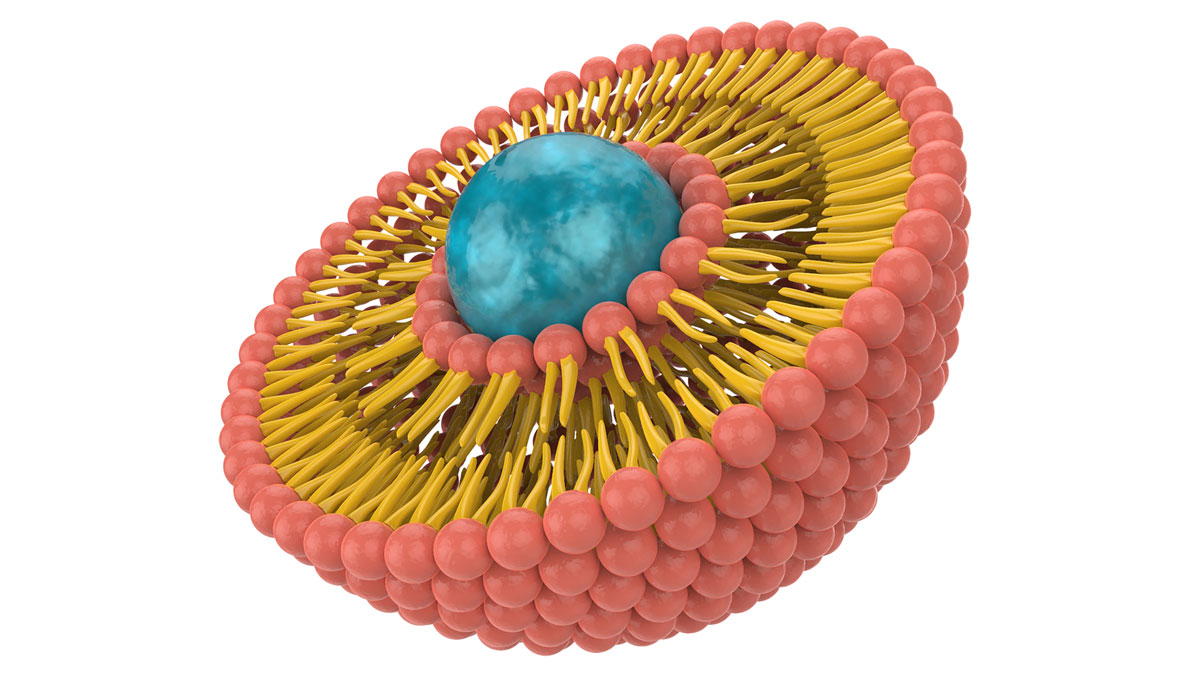

HST Maschinenbau GmbH presents its versatile range of high-pressure homogenizers, designed to enhance product uniformity and stability across diverse industries such as food, pharmaceuticals, cosmetics, and chemicals. These homogenizers operate on a principle of high-pressure turbulence and shear, effectively breaking down fat globules and dispersing particles evenly within liquid matrices. From fresh milk and intravenous lipid emulsions to UV filter lotions and neonicotinoid pesticides, this equipment ensures optimal consistency and longevity of end products. With capacities ranging from 300 liters/hour to 80,000 liters/hour, HST homogenizers cater to both small-scale laboratory setups and large-scale production environments. The units are optionally available in aseptic designs to prevent contamination, with customizable piston materials like chrome and ceramic to maximize durability and reduce maintenance frequency. These homogenizers integrate seamlessly into your production line, offering advanced energy efficiency and minimal noise emissions, meeting stringent industry standards and allowing for easy cleaning and maintenance.

Benefits

- Enhances product consistency and quality by ensuring uniform particle distribution.

- Lowers production costs with reduced energy consumption due to efficient motor control.

- Minimizes risk of contamination with optional aseptic design tailored for sterile processes.

- Extends machine lifespan and reduces maintenance frequency with durable piston materials.

- Integrates effortlessly into existing production lines, supporting scalable operations from lab to full-scale output.

- Applications

- Cream, Sauces, Food industry, Cosmetics, Baby and infant food, Ointments, Chemicals, Colours, Uht milk, Insecticides, Textures, Cell disruption, Beauty creams, Mixed ice cream, Liposomes, Resin dispersions, Latex, Fruit juices, Nanosomes, Pigment dispersions, Vegetable juices, Condensed milk, Egg products, Special drinks, Fresh milk, Pharmaceuticals, Ketchup, Intravenous emulsions, Yoghurt, Wax emulsions, Lubricants, Emulsions, Dressings, Herbicides

- End products

- Uv filter lotions, Glyphosate herbicide, Cell culture media supplements, Glossy automotive wax emulsions, Cortisone ointments, Nanosome encapsulated vitamins, Cornflakes, Intravenous lipid emulsions, Granola, Homogenized automotive paints, Bio-based latex paints, Beeswax furniture polish, Muesli base flakes, Nanosome delivery systems, Neonicotinoid pesticides, Hyaluronic acid serums, Anti-aging creams, Cationic liposome suspensions, Soy lecithin liposomes

- Steps before

- Heat Treatment, Mixing, Blending

- Steps after

- Aseptic Packaging, Cooling, Filling

- Input ingredients

- pressurized product, fat globules, agglomerates, fresh milk, cream, vegetable juices, UHT milk, yoghurt, baby and infant food, condensed milk, ketchup, sauces and dressings, mixed ice cream, fruit juices, egg products, special drinks, intravenous emulsions, liposomes, beauty creams, dyes, ointments, lubricants, fuels/water emulsions, wax emulsions, insecticides, herbicides, resin dispersions, nanosomes, colours, latex

- Output ingredients

- stability, colour intensity, flavour, consistency, long shelf life, increased creaming stability

- Market info

- HST Maschinenbau is known for its expertise in designing and manufacturing custom-engineered industrial machinery, particularly in the sectors of hydraulics and automation, with a strong reputation for quality and innovative solutions tailored to client needs.

- Capacity

- 300 - 80, 000 l/h

- Power

- 5.5 - 400 kW

- Pressure

- 200 bar

- Noise insulation

- Cladding

- Design options

- Aseptic / ATEX

- Valve material

- Stainless steel / Ceramics

- Piston material

- Chrome-plated / Ceramic

- High-pressure homogenization

- Turbulent and laminar forces

- Pressure Range

- 300 bar - 2000 bar

- Automation level

- Manual / PLC

- Batch vs. continuous operation

- Inline Continuous

- Noise control

- Noise insulation cladding

- Aseptic capability

- Aseptic design as an option

- Abrasion resistance

- High-strength stainless steels, special coatings

- Cleanability

- Pneumatically or hydraulically controlled cleaning

- Corrosive resistance (e.g. acids)

- Ceramics, sintered materials

- Noise insulation

- Noisy / Insulated

- Versatility

- Food / Pharmaceuticals / Chemicals

- Piston durability

- High Wear Resistance

- Disruption efficacy

- Cell / Particle

- Machine footprint

- Not specified

- Design Type

- Gaulin design

- Capacity Range (HL Series)

- 5.5 - 250 kW (300 l/h - 35, 000 l/h)

- Capacity Range (HLI Series)

- 55-90 kW (8, 000 - 14, 000 l/h) and 400 kW (up to 80, 000 l/h)

- Capacity Range (HLE Series)

- 3-75 kW (10, 000 l/h – 200 bar)

- Noise Insulation

- Noise insulation cladding available

- Construction Material

- High-strength stainless steels, sintered materials, ceramics

- Homogenizing Valve Types

- PLUG, PILOTED, Multigap

- Piston Versions

- Standard, chrome-plated, ceramic, special HST coating

- Aseptic Design

- Yes, available as an option

- ATEX Design

- Yes, available as an option

- Pneumatic/Hydraulic Control

- Valves controlled pneumatically or hydraulically

- Piston material

- Standard / Chrome-plated / Ceramic / Special HST coating

- Homogenizing valve type

- PLUG / PILOTED / Multigap

- Valve control method

- Pneumatic / Hydraulic

- Aseptic design options

- Septic / Aseptic

- Atex design option

- Available

- Noise insulation option

- Cladding

- Product adaptation

- Individually configured