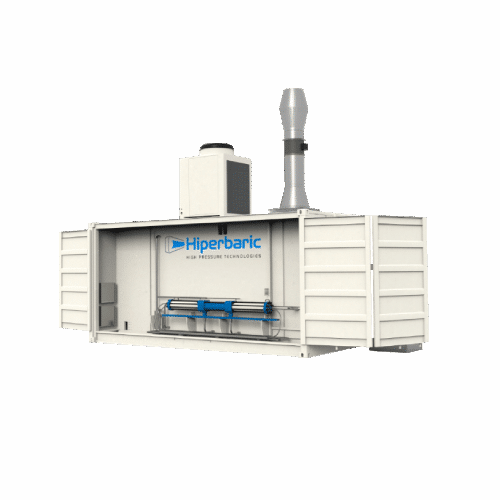

Hydrogen compression solution for refueling stations

For operations demanding efficient hydrogen compression, this modular, two-stage intensifier compressor offers a plug-and-play solution. It ensures optimal cooling and energy efficiency, aligning with sustainability goals while maintaining high purity levels, ideal for modern energy applications.

Compresses and Stores Hydrogen Safely

The Hiperbaric 1KS 95 from Hiperbaric is a modular, scalable high-pressure hydrogen compressor tailored for industrial gas applications. It utilizes a two-stage intensifier system to compress hydrogen up to 950 bar, making it ideal for hydrogen refueling stations and storage facilities. With a capacity of 125 to 550 m³N/h, it ensures high purity due to its oil-free design and efficient cooling with innovative multiplier sleeves. This plug-and-play solution integrates seamlessly into existing operations while requiring less energy for compression, and features a robust venting system for safety. Manufactured to meet international safety standards, the Hiperbaric 1KS 95 is available with engineering support and customization options to fit your specific hydrogen processing needs.

Benefits

- Enhances operational efficiency by delivering high hydrogen purity with reduced contamination risk.

- Optimizes energy usage, minimizing operational costs.

- Adapts to demand fluctuations with modular scalability.

- Facilitates easy integration with plug-and-play setup.

- Complies with stringent safety standards, ensuring secure operation.

- Applications

- Beverages, Meat products, Pet food, Plant based and fruit products, Ready-to-eat (rte) meals, Guacamole and avocado products, Seafood products, Pharma and cosmetics, Baby food and fruit purees, Juices, Salsas, Dairy products

- End products

- Smoked salmon, Chicken curry, Apple puree, Grain-free dog food, Oat milk, Almond milk, Vitamin c serum, Greek yogurt, Tomato salsa, Turkey sausage, Avocado spread, Cold-pressed orange juice

- Steps before

- Steps after

- Input ingredients

- hydrogen gas, H2 inlet pressures, low-pressure hydrogen

- Output ingredients

- compressed hydrogen, high-pressure hydrogen, H2 outlet pressures

- Market info

- Hiperbaric is renowned for its expertise in high-pressure processing (HPP) equipment, offering innovative solutions for food safety and shelf-life extension. The company is recognized for technological innovation, reliability, and strong customer support in the industrial equipment market.

- Inlet Hydrogen Pressure

- 20 - 200 bar

- Delivery Hydrogen Pressure

- Up to 950 bar

- Delivery Hydrogen Pressure

- Up to 95 MPa

- Minimum Flow Rate

- 125 m³N/h - 10 Kg/h

- Maximum Flow Rate

- 550 m³N/h - 50 Kg/h

- Cooling Efficiency

- High

- Compression Efficiency

- High

- Piston Intensifier Cylinder

- Two-stage

- Modular Design

- Scalable

- Oil-Free Design

- Yes

- Cooling System

- Innovative multiplier sleeves

- Vent System

- Efficient

- Automation

- Plug, Play

- Automation level

- PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Cleaning method

- CIP / Manual

- DIRECTIVE 1999/92 / EC

- Risks due to explosive atmospheres

- DIRECTIVE 2014/34 / EU

- Protective equipment and systems for use in potentially explosive atmospheres

- Machine footprint

- Compact and modular design

- Control panel type

- Instrumentation and Control Panel

- Compact footprint

- Plug, Play solution

- Discharge Method

- Pneumatic Circuit