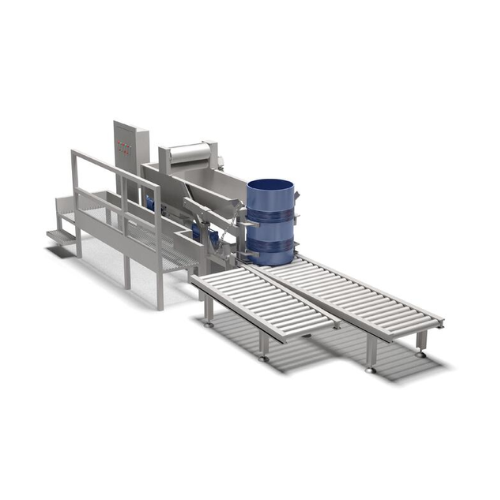

Drum dumper for emptying liquid juice drums

Streamline liquid juice extraction by efficiently emptying and transferring drum contents with precision and minimal waste, ensuring seamless integration into your processing line while maintaining hygienic standards.

Empties and Pumps Liquid Beverages

The Drum Dumper from Bucher Unipektin is a semi-automatic solution engineered specifically for juice and liquid beverage processes. This equipment stands out for its pneumatic double lifting system, which allows for efficient transfer of liquid juice from drums directly into your processing line. Designed for conical and open-top cylindrical drums, it manages capacities of up to 30 drums per hour, with each drum holding up to 200 liters.

Emphasizing semi-automatic operation, the Drum Dumper ensures seamless integration into both processing and pre-processing departments, handling tasks from emptying and pumping to safe drum fastening—all controlled by an intuitive PLC system. Its stainless steel construction ensures robust corrosion resistance and hygiene, with a pneumatic active safety system enhancing operational reliability.

With an optional motorized roller transporter, this equipment facilitates both drum entry and exit in automatic mode, reducing manual handling and improving workflow efficiency. Additionally, its CIP spray cleaning system ensures hygiene standards are easily maintained, critical in food and beverage sectors. Suitable for applications such as orange juice, apple juice, and blended fruit beverages, this versatile dumper is a strategic asset for beverage manufacturers and industrial food processors.

Benefits

- Enhances process efficiency by handling up to 30 drums per hour.

- Reduces manual labor with semi-automatic control and optional motorized drum handling.

- Ensures safety and hygiene with stainless steel construction and a pneumatic safety system.

- Minimizes cleaning time with an integrated CIP spray system.

- Facilitates quick integration into existing lines with flexible pneumatic connections.

- Applications

- Juice, Liquid beverages

- End products

- Lemonade, Concentrated fruit mixers, Flavored water, Apple juice, Herbal extracts in liquid form, Orange juice, Grape juice, Sport drinks, Blended fruit beverages, Cranberry juice

- Steps before

- Juice Extraction, Juice Storage

- Steps after

- Pumping, Further Processing, Filling, Packaging

- Input ingredients

- liquid juice, drums

- Output ingredients

- discharged product, pumped product

- Market info

- Bucher Unipektin is known for producing advanced equipment and systems for the food and beverage industry, specializing in juice processing and filtration technologies with a reputation for innovative solutions and reliable, high-quality products.

- Automation

- Semi-automatic

- Pneumatic System

- Double lifting system

- Safety Features

- Pneumatic active safety system

- Cleaning System

- CIP spray cleaning system

- Processing capacity

- 20 - 30 drums/h

- Drum Type

- Open-top cylindrical and conical

- Drum Capacity

- 200L

- Hopper Capacity

- 600L

- CIP Connection

- Female thread G ¾

- Pneumatic Connection

- Quick connector Ø10

- Drum Transporter

- Optional motorised roller transporter

- Working mechanism

- Semi-automatic tipping system

- Integrated steps

- Drum fastening, pneumatic lifting, CIP cleaning

- CIP principles

- CIP spray cleaning system

- Batch vs. continuous operation

- Batch (20 - 30 drums/h)

- Automation level

- Semi-automatic

- Cleaning method

- CIP

- Safety features

- Pneumatic active safety system

- Operator access

- Side operator platform with stainless steel non-slip steps

- Cleanability

- Yes, CIP spray cleaning system

- Corrosive resistance

- Stainless steel parts

- Biological compatibility

- Yes, with food-grade standards

- Container type

- Open-top cylindrical and conical

- Control panel type

- Lever-controlled

- Operator platform type

- Stainless steel non-slip steps

- Discharge method

- Pneumatic double lifting system

- Bag emptying system

- Optional

- Roller transporter

- Motorised, optional