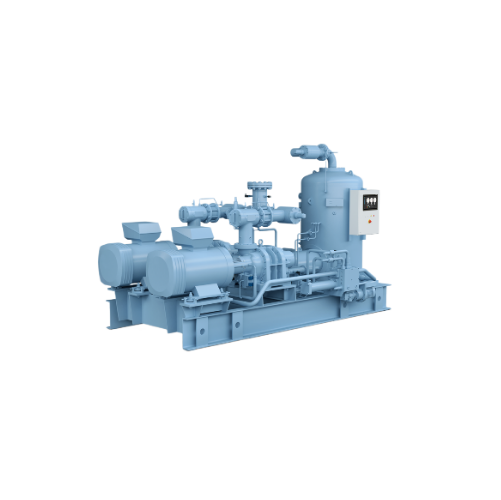

Industrial screw compressor systems for cooling applications

Maximize energy efficiency and system redundancy with parallel screw compressor systems, designed for seamless integration and optimal cooling performance across diverse industrial processes.

Optimizes Cooling and Refrigeration Processes

The Grasso SPduo from GEA is a compact, dual screw compressor system designed to enhance efficiency and reliability in various cooling and refrigeration applications. Its unique parallel compressor design allows for independent or simultaneous operation, maximizing efficiency across load conditions. Ideal for industries such as food processing, pharmaceuticals, and energy, it supports end-products from chilled beverages to biopharmaceuticals. With a cooling capacity range from 344 to 3,982 kW, the SPduo features variable speed drive motors and seamless capacity control via a frequency inverter, reducing energy consumption significantly. Its integrated GEA Omni control panel offers user-friendly operation with a high-definition touch screen. Built on a common base frame with shared oil circuit and controls, it simplifies installation and maintenance while occupying a smaller footprint. The system meets industry standards for energy efficiency and operational redundancy, proving indispensable for continuous and automated production environments.

Benefits

- Enhances operational flexibility and uptime with independent or dual compressor operation.

- Reduces energy usage by employing variable speed drive motors for efficient part-load management.

- Simplifies installation and maintenance with a compact footprint and shared infrastructure.

- Supports diverse applications from food processing to pharmaceuticals, ensuring versatility in production lines.

- Offers reliable redundancy, ensuring continuous operation even during maintenance or unexpected downtimes.

- Applications

- Chemical processing, Beverage processing, Industrial refrigeration, Refrigeration, Pharmaceutical processing, Food processing, Cooling systems, Energy sector, Heating applications, Hvac

- End products

- Heat exchangers, Dairy products, Frozen vegetables, Refrigerants, Biopharmaceuticals, Ice cream, Chilled beverages, Chemical solvents, Pharmaceutical vaccines, Fruit juices

- Steps before

- Purification, Emulsification, Grinding

- Steps after

- Packing, Coating

- Input ingredients

- refrigerant R717, refrigerant R290

- Output ingredients

- cooling capacity, kW

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Speed

- 1, 000 - 4, 500 rpm

- Cooling Capacity

- 344 to 3, 982 kW

- Part-load Capability

- Down to 12%

- Compressor Type

- Screw compressor

- Cooling Medium

- R717

- Temperature Range

- -10/+35°C

- Control System

- GEA Omni control panel

- Speed Control Method

- Variable speed drive motor

- Footprint

- Minimized footprint

- Working mechanism

- Parallel screw compressor operation

- Variable speed control

- 1000–4500 rpm

- Efficiency across load conditions

- High efficiency at part/load and full load

- Redundancy

- Dual independent screw compressors

- Capacity control

- Stepless capacity via frequency inverter and/or slide system

- Installation footprint

- Compact unit design

- Cooling capacity range

- 344 to 3, 982 kW

- Load flexibility

- Part-load operation down to 12%

- Simplicity in maintenance

- Common base frame and control system

- Integration and control

- GEA Omni control panel with touch screen

- Temperature resistance

- Up to 135°C

- Redundancy

- Inbuilt

- Compact footprint

- Single, compact unit

- Base frame

- Common base frame

- Package type

- Packaged screw compressor systems

- Control panel type

- GEA Omni control panel with high-definition 15.6" touch screen

- Integration possibilities

- Partially customizable with a third parallel compressor driveline on special request

- Variable speed drive motors

- Speed range 1, 000 - 4, 500 rpm (R to T models 1, 500 - 4, 500 rpm, P and V to Y models 1, 500 - 3, 600 rpm)