Conveyor system for efficient container transport

Optimize your filling line with a versatile container transport system designed for high-speed precision, ensuring safe and quiet handling of various container types while seamlessly integrating with your existing setup.

Transports and Stabilizes Multi-Type Containers

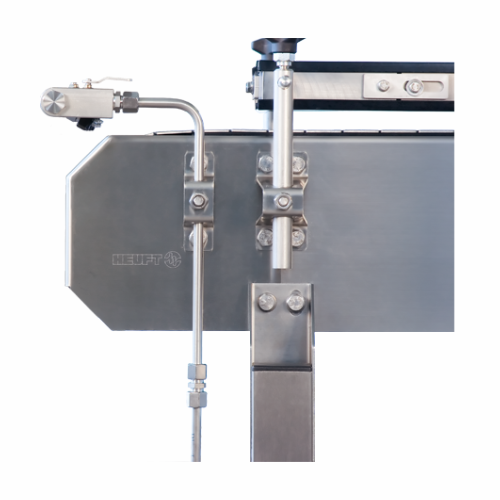

The HEUFT conveyor system is engineered to enhance container transport efficiency across diverse industries such as beverage, food, and pharmaceuticals. It features a robust design using magnetically stabilized chains and container-friendly guide rails, ensuring reliable handling of various container types including soft drink bottles, milk cartons, and pharmaceutical vials. This system excels at operating continuously in both single and multi-lane configurations, accommodating high-speed production demands. Its open-construction design simplifies cleaning and maintenance while minimizing noise, making it ideal for hygiene-sensitive environments. Each HEUFT conveyor is highly customizable and supports seamless integration into existing lines, ensuring optimal space utilization and adaptability to specific plant layouts.

Benefits

- Enhances operational efficiency with seamless integration into high-speed production lines.

- Reduces downtime through robust construction and easy maintenance.

- Minimizes noise levels, creating a safer and more comfortable workplace.

- Customizable configurations provide flexibility for unique production requirements.

- Ensures product safety with clean, hygienic transport solutions.

- Applications

- Food, Beverages, Pharmaceuticals

- End products

- Beer bottles, Medicine bottles, Bottled water, Canned foods, Milk cartons, Juice containers, Tablet containers, Pharmaceutical vials, Packaged snacks, Soft drinks

- Steps before

- Line planning, Container preparation, Filling, Labeling

- Steps after

- Fault rejection, Package inspection, Integration into existing systems

- Input ingredients

- empty containers, full containers

- Output ingredients

- transported containers

- Market info

- HEUFT is known for its expertise in inline quality inspection systems and automation solutions for the food, beverage, and pharmaceutical industries, with a reputation for innovation and reliability in ensuring product safety and integrity.

- Transport Speed

- Fast

- Lane Configuration

- Single-lane / Multi-lane

- Material Type

- Robust

- Noise Level

- Low

- Flexibility

- High

- Construction Type

- Open

- Maintenance

- Easy

- Cleaning Method

- Optimized for cleaning

- Component Type

- High-quality

- Support Type

- Robust

- Guide Rails

- Container-friendly plastic profiles

- Integration

- Problem-free

- System Adaptation

- Optimal adaptation to on-site conditions

- Component Addition

- Space-saving and compact

- Cable Routing

- Open / Closed

- Curve Radii

- Variety available

- Automation level

- Manual / PLC / SCADA

- Cleaning method

- CIP / Manual

- Batch vs. continuous operation

- Batch / Inline Continuous

- Line flexibility

- Single-lane / Multi-lane

- Noise level

- Low-noise operation

- Material handling capability

- Empty and Full Containers

- Installation and Integration

- Problem-free integration into existing systems

- Abrasion resistance

- High

- Cleanability

- Optimized for maintenance and cleaning

- Corrosive resistance (e.g. acids)

- Yes, robust materials used

- Density/particle size

- Adapted for various container types

- Compact footprint

- Yes

- Discharge method

- Single-lane or multi-lane

- Material

- Robust construction with plastic profiles

- Design

- Open, space-saving and compact

- Customizability

- Individually assembled for specific conditions

- Noise level

- Low-noise operation

- Lane Configuration

- Single-lane / Multi-lane

- Space Adaptability

- Compact / Space-saving design

- System Integration

- Compatible with existing conveyor systems

- Cleaning Compatibility

- Designed for easy cleaning

- Construction Type

- Open / Robust construction

- Assembly

- Individually assembled

- Guide Rail Adjustability

- Tool-less adjustment

- Curved Guide Rails

- Adjustable radii without tools

- Cable Routing Options

- Open / Closed

- Material Options

- Container-friendly plastics