Cold aseptic filling system for beverages

Ensure microbiological safety and high product quality with a versatile cold aseptic filling system that combines deaeration, blending, and pasteurization to meet the demands of sensitive beverage production.

Ensures Sterile Beverage Preparation and Filling

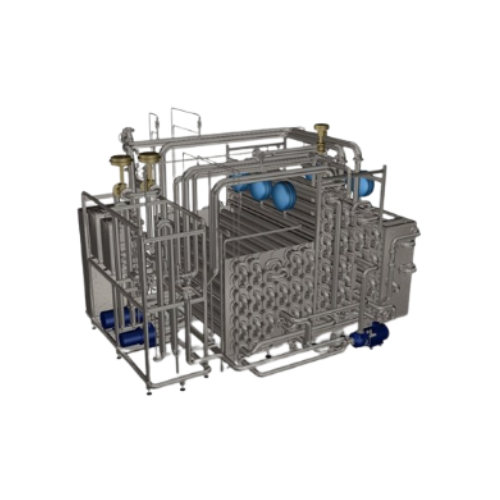

The Innopro ACF from KHS Group is a sophisticated aseptic filling process system designed for beverage manufacturers and food producers striving for microbiological sterility. This system undertakes critical operations such as deaeration, blending, pasteurization, buffering, and beverage-sterile control, ensuring high-quality preparation of liquids like juices, sodas, and energy drinks. Operating continuously at high speed, the Innopro ACF offers a throughput capacity of 3-51 m³ per hour.

The system’s compact, skid-mounted design facilitates seamless integration into existing production lines, enhanced by uniform operating, visualization, and software systems that reduce manual intervention. Its sustainable operation is powered by a carefully orchestrated layout, minimizing energy consumption and prolonging the service life of process components. Made with durable materials, the Innopro ACF maintains excellent hygiene standards, bolstered by Certified Aseptic Process parameters.

Incorporation into your production line is effortless due to the system’s compatibility with upstream and downstream processes, serving a wide range of applications from still water to mixed alcoholic beverages. KHS provides engineering support for customization needs, ensuring alignment with specific product specifications and operational requirements. Whether handling raspberry syrup or protein recovery shakes, the Innopro ACF guarantees sterile, non-reinfective preparation with consistently high product quality.

Benefits

- Ensures microbiological sterility, enhancing beverage safety and quality.

- Compact design saves floor space, integrating easily into existing systems.

- Reduces operator intervention with uniform system controls and visualization.

- Decreases energy consumption through coordinated system layout, lowering operational costs.

- Extends service life with durable, skid-mounted construction, minimizing maintenance requirements.

- Applications

- Beverages, Syrup, Mixed milk, Milk, Tea and coffee beverages, Iced tea, Juice spritzers, Still water, Energy drinks, Mixed alcoholic beverages, Juices, Soft drinks, Sport and health drinks

- End products

- Cocktail mixers, Apple juice, Whole milk, Orange juice, Lemon-lime soda, Sparkling cider, Lemon iced tea, Raspberry syrup, Cold brew coffee, Bottled spring water, Protein recovery shake, Ginseng energy drink, Chocolate milk

- Steps before

- Deaeration, Blending, Pasteurization

- Steps after

- Buffering, Sterile beverage preparation, Packing

- Input ingredients

- syrup, soda pop, iced tea, juice, juice spritzers, energy drinks, sport drinks, health drinks, mixed milk, tea beverages, coffee beverages, mixed alcoholic beverages

- Output ingredients

- microbiologically sterile bottles, hygienically perfect beverages, consistently high product quality

- Market info

- KHS is known for manufacturing innovative filling and packaging systems for the beverage, food, and non-food industries, renowned for their engineering expertise, high-quality standards, and sustainable solutions in ensuring efficient production processes.

- Output

- 3-51 m³/hour

- Process Type

- Deaeration, Blending, Pasteurization, Buffering

- Design

- Compact, Skid-mounted

- Sterility

- Beverage-sterile, non-reinfective product control

- Compatibility

- Range of beverages

- Operation

- Simple operation and monitoring

- Energy Consumption

- Reduced through coordinated layout

- Working Mechanism

- Cold Aseptic Filling

- Integrated Steps

- Deaeration, Blending, Pasteurization, Buffering

- CIP/SIP

- CIP 121°C

- Batch vs. Continuous Operation

- Batch/Inline

- Automation Level

- PLC/SCADA

- Energy Efficiency

- Optimized for Reduced Consumption

- Process Control

- Beverage-Sterile, Non-Reinfective

- Compact Design

- Skid-Mounted

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Heat Sensitivity

- Process sensitive to thermal changes

- Container Size

- 250 ml – 2 L

- Container Type

- Plastic (PET)

- Machine footprint

- Compact design

- Discharge method

- Sterile, non-reinfective discharge

- Control panel type

- Process visualization with transparency

- Adaptability

- Flexible and adaptable to product specifications

- Compact footprint

- Yes

- Control panel type

- Touchscreen HMI

- Integration possibilities

- SCADA / MES

- Skid-mounted design

- Yes

- Process modules

- Customizable