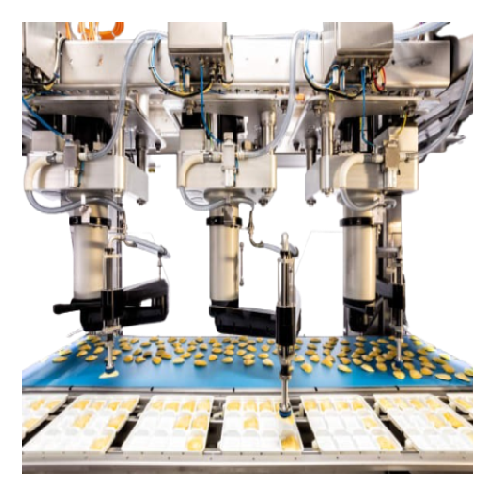

Pick & place vision system for packaging quality control

Ensure flawless product packaging with a vision system that enhances quality control, precisely handling items to minimize waste and optimize efficiency in continuous, high-speed production lines.

Enhances Quality Control and Precision Packaging

The Pick & Place Vision System from Schubert is a modular imaging solution essential for precision in automated packaging operations. Tailored for industries ranging from food to pharmaceuticals, it ensures flawless product handling and quality control by integrating 2D and 3D scanners for accurate shape, color, and dimensional inspections. The system enhances throughput by observing continuous product flow and feeding precise positional data to robotic pick & place systems. It supports label verification crucial for pharmaceutical and cosmetic packaging, using reflected-light scanners that deliver reliable label and code inspection. Offering seamless integration into existing lines, this equipment minimizes rejects and operational costs while ensuring high-quality output. Designed for robustness, the system features modular components to fit diverse packaging requirements, with options for use in high tolerance production environments. Future-ready, it incorporates neuronal networks, enabling it to adapt to new products independently, thus reducing the need for manual reprogramming and scaling efficiency across production lines.

Benefits

- Enhances product quality by minimizing defects and rejects.

- Increases operational efficiency with automated precision handling.

- Lowers production costs through reduced manual inspection needs.

- Adapts to new product types autonomously with AI integration.

- Ensures compliance with industry standards for labeling accuracy.

- Applications

- Food, Beverages, Snacks, Pet food, Confectionery, Cosmetics, Pharma, Bakery products, Dairy

- End products

- Cookies, Biscuits, Face cream jars, Cheese slices, Dog treats, Chocolates, Milk cartons, Juice boxes, Vitamin tablets, Yogurt cups, Candy bars, Croissants, Shampoo bottles

- Steps before

- Product Sorting, Product Alignment

- Steps after

- Quality Inspection, Final Packing

- Input ingredients

- unsorted products, bakery products, confectionery, snacks, dairy, beverages, pharmaceutical labels, cosmetics, pet food

- Output ingredients

- packaged products, flow-wrapped products, case-packed products, label-verified products

- Market info

- Schubert Group is renowned for its innovative packaging technology solutions, specializing in modular, highly flexible packaging machines for various industries, ensuring efficiency and precision in production lines.

- Automation

- Automated pick, place

- Vision System Type

- 2D and 3D

- Quality Control

- Automated and efficient

- Module Size

- 200 mm - 1800 mm

- Scanner Type

- Incident-light and 3D scanners

- Lighting

- Integrated

- Image Processing

- Modular image processing system

- Height Control

- Precise height control

- Shape Control

- Precise shape control

- Dimensional Control

- Precise dimensional control

- Color Control

- Precise color control

- Neuronal Networks and AI

- Future implementation

- Label and Code Verification

- Flash lighting and still image

- Product Position Recognition

- Recognized by vision system

- 3D Camera System

- Used for unsorted group of products

- Light Pattern Projection

- Unique Schubert light pattern

- Working mechanism

- Pick, place vision system

- Automation level

- Robotic integration

- Quality control

- Automated with vision system

- Batch vs. continuous operation

- Continuous

- Product flow monitoring

- Line sensors, 3D scanners

- Position detection

- Vision system precision

- Error reduction

- Fewer rejects, complaints

- Neuronal networks

- Future AI integration

- Modularity

- 200 mm-wide modules

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product flow

- Continuous

- Complex product handling

- Yes

- Unsorted group handling

- Yes

- Modular design

- 200 mm-wide modules, extendable up to 1800 mm

- Scanner type

- Incident-light scanners, 3D scanners

- Working width

- Up to 1800 mm

- Control system

- Vision system integration

- Lighting system

- Integrated lighting

- Camera system

- 4 cameras and 2 light pattern projectors

- Automation level

- Fully automated vision system

- Vision capabilities

- 2D and 3D imaging

- Image Processing Configuration

- Modular design

- Vision System Type

- 2D and 3D imaging

- Lighting Type

- Integrated lighting

- Scanner Module Size

- 200mm per module

- Scanner Working Width

- Up to 1800mm

- Neuronal Networks Integration

- AI for future adaptation