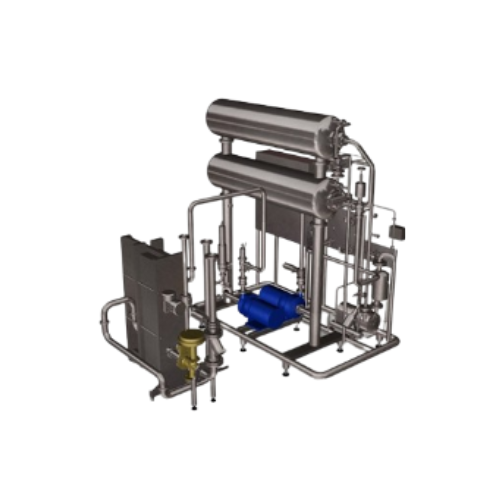

Water deaerator for beverage production

Enhance the quality and extend the shelf life of your beverages with our cutting-edge water deaerator, ensuring low oxygen content for optimal flavor and stability in every drop.

Deaerates and Monitors Beverage Liquids

The Innopro DOX water deaerating system from KHS Group is engineered for precision deaeration across a spectrum of beverages, including beer, juices, soft drinks, and dairy. Utilizing a two-stage, horizontal vacuum-assisted deaeration process, it effectively reduces oxygen levels, ensuring product integrity and shelf life extension.

Capable of processing up to 80,000 liters per hour, the Innopro DOX offers high-speed, fully automated operation with integrated monitoring features to ensure optimal deaeration levels at all times. Optional cooling stages further enhance its versatility for specific thermal sensitivities in your production line.

This system’s resource efficiency is notable, requiring minimal CO2 as a stripping gas, thanks to its vacuum deaeration principle, thus minimizing operational costs and environmental impact. Constructed with durable materials, it ensures longevity and compliance with industry standards across beverage, brewing, food, and non-food sectors.

Easy integration into existing lines is achieved through its advanced automation, while its design facilitates seamless cleaning and maintenance, reducing downtime and maintaining operational efficiency. The Innopro DOX is customizable to meet unique production needs, backed by KHS’ engineering expertise and support.

Benefits

- Enhances product quality by maintaining minimal residual oxygen levels.

- Increases production efficiency with a throughput of up to 80,000 liters per hour.

- Saves on operational costs with low CO2 consumption due to vacuum-assisted deaeration.

- Integrates seamlessly into existing lines with automated, continuous operation.

- Supports product versatility with optional cooling stages for temperature-sensitive products.

- Applications

- Beverage water, Wine, Milk, Iced tea, Spirits, Still water, Juice, Brewing industry water, Soft drinks, Beer, Sparkling wine

- End products

- Champagne, Bottled water, Red wine, Lemon iced tea, White wine, Whole milk, Mineral water, Craft beer, Skimmed milk, Orange juice, Pilsner beer, Vodka, Apple juice, Lager beer, Whiskey, Peach iced tea, Stout beer, Carbonated soft drinks, Flavored soft drinks, Prosecco, Gin

- Steps before

- Water Purification, Filtration, Water Supply, Water Mixing

- Steps after

- Filling, Packaging, Cooling, Oxygen Monitoring

- Input ingredients

- beverage water, water for brewing industry, water

- Output ingredients

- deaerated water, low residual O2 content, water with excellent deaeration values

- Market info

- KHS is known for manufacturing innovative filling and packaging systems for the beverage, food, and non-food industries, renowned for their engineering expertise, high-quality standards, and sustainable solutions in ensuring efficient production processes.

- Deaeration Capacity

- up to 80, 000 liters/hour

- Automation

- Fully automatic

- Residual Oxygen Content

- Minimum

- CO2 Consumption

- Low

- Energy Efficiency

- High

- Cooling Option

- Optional cooling stage

- Product Quality Consistency

- High throughout process

- Monitoring Capability

- Permanent monitoring of deaeration values

- Working mechanism

- Two-stage, horizontal water deaerator

- CIP/SIP

- Fully automatic

- Batch vs. continuous operation

- Continuous

- Automation level

- Fully automatic

- Integration with process monitoring

- Permanent monitoring of deaeration values

- Energy efficiency

- High energy efficiency with integrated water cooling

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Water type

- Beverage/Brewing

- Compact footprint

- Built to save space

- Control panel type

- HMI/PLC integrated

- Integration possibilities

- Remote monitoring and control

- Cooling option

- Optional cooling stage