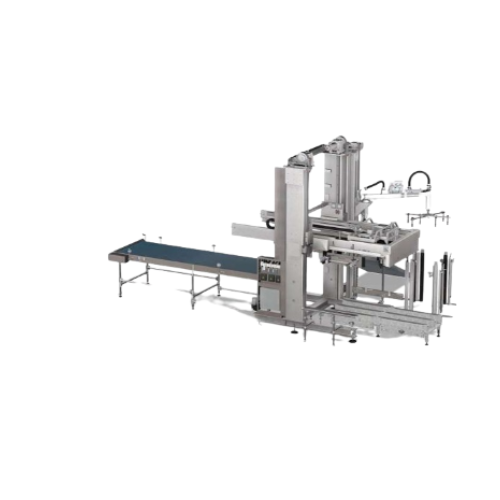

Depalletizer with accurate level compensation

Optimize your high-speed assembly line with a depalletizer designed for precise level adjustment, ensuring seamless handling of diverse container types, from glass to plastic. Suitable for operations that demand quick changeovers and robust modular setups, enhancing both efficiency and reliability in continuous production environments.

Depalletizes and Reconfigures Layered Containers

The Innopal AS N depalletizer from KHS Group is a robust twin-column system designed to streamline operations for beverage, food, and non-food product manufacturers. Distinguished by its motor-driven, adjustable pushoff frame, this depalletizer offers versatility for various containers, including glass, plastic, and metal. Capable of handling up to 240 depalletized layers per hour, it ensures rapid and efficient preparation for filling and packaging lines. Its consistent modular design and optional fully automatic layer changeover enhance flexibility in production tasks, making it an ideal choice for high-speed, continuous operations. The equipment’s integration into existing lines is seamless, supported by its advanced automation and minimal maintenance needs, thanks to the use of servo technology and cog belts. The plastic coating on product contact surfaces reduces noise and wear, contributing to a quieter, more sustainable operation. Suitable for beverage producers, food processors, and packaging companies, the Innopal AS N depalletizer supports a wide range of end products, from beer and juice bottles to household cleaning sprays.

Benefits

- Enhances operational efficiency with seamless layer changeovers during active production.

- Minimizes maintenance demands due to durable servo technology and reduced parts.

- Lowers operational noise, contributing to a more pleasant production environment.

- Adapts to diverse container types, ensuring flexibility across multiple product lines.

- Elevates system availability with modular design, supporting high-speed continuous operation.

- Applications

- Food, Beverages, Liquid food, Wine, Milk, Nonfood, Metal containers, Iced tea, Spirits, Still water, Glass containers, Plastic containers, Homecare products, Juice, Soft drinks, Beer, Sparkling wine

- End products

- Beer bottles, Carbonated soft drink cans, Shampoo bottles, Vodka bottles, Pasteurized milk cartons, Mineral water bottles, Baby food jars, Detergent plastic bottles, Orange juice bottles, Iced tea plastic bottles, Household cleaning sprays, Champagne bottles, Aluminum soda cans, Wine glass bottles

- Steps before

- Container design, Syrup room processing, System planning, Recyclable barrier application, Handle systems integration

- Steps after

- Packing, Secondary packaging, Labeling, Line optimization, Digital integration

- Input ingredients

- new glass containers, plastic containers, metal containers

- Output ingredients

- depalletized layers

- Market info

- KHS is known for manufacturing innovative filling and packaging systems for the beverage, food, and non-food industries, renowned for their engineering expertise, high-quality standards, and sustainable solutions in ensuring efficient production processes.

- Capacity

- up to 240 depalletized layers/h

- Automation

- Motor-driven adjustable pushoff frame

- Automation

- Fully automatic layer changeover

- No. of Parts

- Reduced number for diminishing spare parts costs

- Noise Level

- Low-noise operation

- Operation Flexibility

- Flexible when changing products

- Automation Control

- Servo technology and cog belts

- Automation level

- Manual / PLC / SCADA

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Batch vs. continuous operation

- Batch / Inline Continuous

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Plastic compatibility

- Yes

- Metal compatibility

- Yes

- Glass compatibility

- Yes

- Container type

- Glass / PET / Metal

- Container size

- Variable

- Flexibility

- High

- Product throughput

- Up to 240 layers/h

- Palletizing tasks

- Various configurations

- Pushoff frame

- Motor-driven, adjustable

- Column type

- Twin-column

- Surface coating

- Plastic-coated

- Control panel type

- HMI / Touchscreen

- Integration possibilities

- KHS machine automation / RFID access

- Flexible product changeover

- Motor-driven adjustable pushoff frame

- System planning customization

- Turnkey / Ready-to-operate systems

- Layer changeover automation

- Fully automatic

- Flexibility in palletizing tasks

- Accurate level compensation