Water deaeration system for beverages

Achieve ultra-low oxygen content in beverage water to enhance taste and prolong shelf-life with precise vacuum deaeration and CO2 integration, perfect for both still and carbonated drink production.

Minimizes Oxygen in Beverage Production

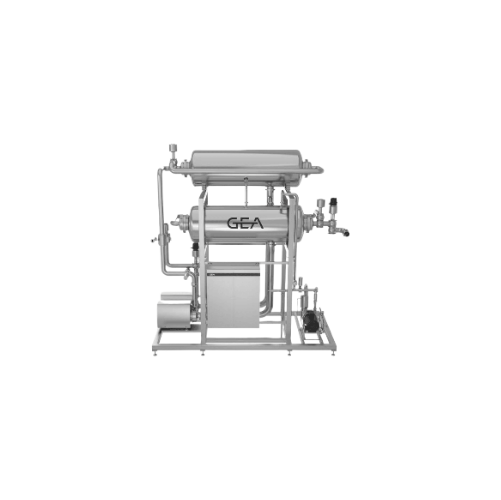

The GEA DIOX-2 from GEA Group is a two-stage water deaeration system designed for beverage manufacturers aiming to enhance product quality by minimizing oxygen content. It operates through a sequential vacuum system, initially removing the majority of oxygen and further flushing out residual gases with CO2. This precise oxygen extraction is crucial for producing high-quality carbonated and non-carbonated beverages such as soft drinks, flavored waters, and fruit juices, ensuring prolonged shelf-life and unaltered flavors. The system offers flexibility with a throughput range of 50 to 900 hl/h, allowing seamless integration into existing production lines. Its compact design demands minimal space while ensuring low energy consumption, driven by integrated temperature control and optional sealing water cooling. Constructed with 316L stainless steel for excellent corrosion resistance, the GEA DIOX-2 supports sustainable operations with low CO2 usage and reduced operating costs. Cleaning is straightforward through its CIP-compatible design, facilitating ease of maintenance and minimal downtime.

Benefits

- Enhances beverage flavor stability and shelf-life by effectively reducing water oxygen content.

- Ensures seamless production integration with a compact design requiring minimal space.

- Lowers operational expenses with reduced CO2 and energy consumption.

- Offers versatile production with configurable flow rates between 50 to 900 hl/h.

- Simplifies maintenance processes through contamination-free CIP compatibility.

- Applications

- Beverage, Non-carbonated beverages, Carbonated drinks

- End products

- Lemonade, Iced tea, Still water, Sparkling water, Energy drinks, Carbonated soft drinks, Fruit juices, Flavored water

- Steps before

- Water Supply Preparation, Initial Oxygen Removal

- Steps after

- Beverage Mixing, Carbonation, Bottling, Packaging

- Input ingredients

- beverage water, CO2, oxygen

- Output ingredients

- deaerated water, CO2-oxygen mixture

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Residual oxygen content

- ≤ 0.05 mg/l (≤ 50 ppb)

- Flow rate

- 50 hl/h to 900 hl/h

- Water admission pressure

- 3.5 bar

- Water temperature

- >10°C

- Control air pressure

- 6 - 8 bar

- Materials

- 1.4404 (316L) / EPDM

- CO2 admission pressure

- 6 - 8 bar

- CO2 consumption

- 0 - 0.5 g/l

- CO2 quality

- ≥99.99% purity

- Energy demand

- Low

- Working Mechanism

- Two-stage vacuum deaeration

- Integrated Steps

- Vacuum deaeration, CO2 addition, oxygen extraction

- Automation Level

- Manual / PLC

- Batch vs. Continuous Operation

- Inline Continuous

- CIP/SIP

- CIP via product path

- Energy Efficiency

- Low energy demand

- Changeover Time

- Short installation time

- Cleaning Method

- CIP via product path

- Sealing Water Consumption

- Reduced with integrated temperature control

- Cleanability

- Yes

- Corrosive resistance (e.g. acids)

- Yes

- Water type

- Deaerated beverage water

- Compact footprint

- Compact system with relatively small footprint

- System Shape

- Pre-assembled unit

- Size

- Configurable for flow rates of between 50 hl/h and 900 hl/h

- Weight

- No information available

- Height

- Low height requirements

- Installation time

- Short installation time

- Control panel type

- Pre-assembled unit

- Integration possibilities

- Simple integration into existing systems

- Footprint

- Compact system with small footprint

- Flow rate configurability

- Between 50 hl/h and 900 hl/h

- Sealing water cooler

- Optional