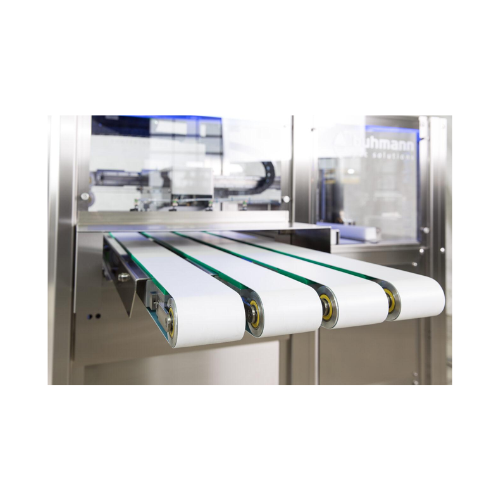

Conveyor system for aligning, sorting, and transporting products

Streamline your packaging line by efficiently aligning, sorting, and transporting diverse products with a modular conveyor system designed to handle everything from thermoformed packs to snack pouches with precision and flexibility.

Aligns, Sorts, Mixes, and Transports Products

The SERVOFEED PF900 from Buhmann Pac Solutions is an innovative modular conveyor and belt system designed for seamless integration into your production and packaging lines. This system excels in aligning, sorting, mixing, and transporting diverse products such as thermoformed packs, pouches, cups, bottles, and cosmetic blister packs. Ideal for food and non-food manufacturers, it offers flexible format options and automatic format change capabilities to meet varying product needs.

The PF900 operates continuously at high speed while maintaining precise control, enhancing productivity in industries like food, packaging, and logistics. Its modular design allows for customization to fit specific production requirements, connecting efficiently with upstream filling machines and downstream palletizing systems.

Engineered for both solid and liquid products, the SERVOFEED PF900 ensures reliable handling of items ranging from yogurt cups to detergent pods. Its robust construction supports a range of materials, providing lasting performance in demanding manufacturing environments. The system’s user-friendly interface and optional automation features facilitate smooth operation and minimal maintenance, making it an indispensable asset for optimizing packaging and transport operations.

Benefits

- Increases production efficiency with high-speed, continuous operation.

- Enhances flexibility through automated format changes for diverse product types.

- Streamlines integration with existing lines, minimizing downtime and transition efforts.

- Reduces labor costs with easy-to-use modular configuration and automated control features.

- Adapts to various industrial applications, supporting both solid and liquid products efficiently.

- Applications

- Cardboard boxes, Blisters, Bottles, Cups, Pouches, Thermoformed packs

- End products

- Breakfast cereal boxes, Cosmetic blister packs, Sauce sachets, Snack packs, Pill blisters, Custom gift boxes, Chocolate pouches, Yogurt cups, Juice bottles, Detergent pods

- Steps before

- Filling, Product Packaging

- Steps after

- Final Packaging, Palletizing

- Input ingredients

- thermoformed packs, pouches, cups, bottles, blisters, empty packages, filled packages, cardboard boxes

- Output ingredients

- aligned products, sorted products, mixed products, transported products

- Market info

- Buhmann Systeme is known for designing and manufacturing engineered-to-order packaging machines and systems, excelling in automation and high-tech solutions for various industries, enhancing efficiency and reliability in production lines.

- Automation

- Modular, Configurable

- Product Handling

- Aligning, Sorting, Mixing, Transporting

- Integration

- Compatible with Filling, Packaging, Palletizing Systems

- Format Flexibility

- Various Product Grouping

- System Type

- Conveyor, Belt System

- Product Compatibility

- Thermoformed Packs, Pouches, Cups, Bottles, Blisters

- Format Change

- Optional Automatic

- Capacity

- Up to 36, 000 Products per Hour

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Inline Continuous

- Cleaning method

- Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Belt system integration

- Modular

- System configuration

- Individual modular

- Integration with Packaging Lines

- Yes

- Format Flexibility

- Flexible format options

- Product Grouping

- Individual product grouping

- Presentation Type

- Standing, lying presentation

- Automatic Format Change

- Optional