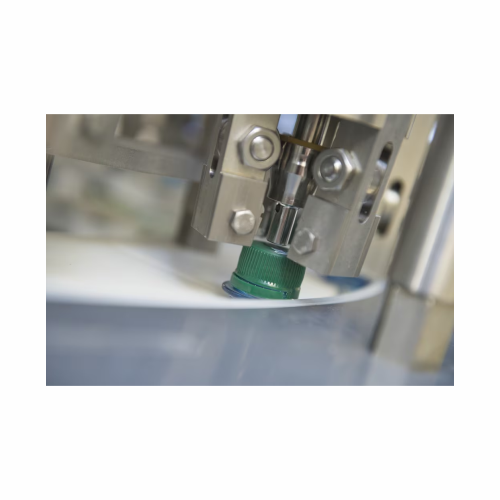

Decapper for removing screw caps

Efficiently unscrew caps from various bottle types without damaging the threads, even under challenging conditions, ensuring seamless operation and reducing downtime in high-speed bottling lines.

Unscrews and Removes Bottle Caps Efficiently

The Rotomat series by Krones is designed for efficient removal of screw caps in diverse beverage processing environments. This rotary decapper utilizes a multi-gripper head that ensures precise unscrewing without damaging bottle threads. Suitable for soft drinks, spirits, water, milk-based beverages, and juices, its applications extend across bottling, packaging, and recycling industries. It supports line outputs of up to 60,000 bottles per hour, suitable for high-speed, continuous operations. The system’s automation integrates seamlessly into existing production lines, featuring automatic height adjustment and low-noise operation. Constructed from stainless steel AISI 304, it guarantees durability and corrosion resistance. The modular design accommodates various layout configurations, enabling installation flexibility in tight production spaces. With roller-controlled grippers and a compact footprint, it ensures high reliability and minimal maintenance downtime.

Benefits

- Maximizes production line efficiency with high-speed decapping up to 60,000 bottles per hour.

- Ensures precise cap removal without thread damage, protecting bottle integrity.

- Offers flexible installation options with modular design adaptable to existing layouts.

- Minimizes maintenance needs due to durable, low-wear components.

- Enhances operational hygiene with a design focused on reduced surface areas and clear unit separation.

- Applications

- Water, Bottled beverages, Milk and milk-based drinks, Aseptic systems, Spirits, Juice, Soft drinks, Returnables line

- End products

- Mineral water, Aseptic packaged drinks, Orange juice, Refillable glass bottles, Pet bottled beverages, Carbonated soft drinks, Flavored milk, Bottled spirits

- Steps before

- Filling, Sorting, Capping

- Steps after

- Inspection, Packaging, Labeling

- Input ingredients

- bottles with screw caps, metal screw caps, plastic screw caps

- Output ingredients

- bottles without screw caps

- Market info

- Krones is renowned for its expertise in manufacturing beverage and liquid food processing and packaging equipment, offering comprehensive solutions that include filling, packaging technology, and processing systems, and is reputed for innovation and quality in the industry.

- Cap Diameter

- Up to 50 millimetres

- Line Output

- Up to 60, 000 bottles per hour

- Decapping Heads

- 6 to 25

- Material

- Stainless steel AISI 304

- Noise Levels

- Low-noise

- Operation

- Rotary machine with different layout configurations

- Working mechanism

- Rotary machine with decapping heads

- Cap size compatibility

- Up to 50 mm diameter

- Capacity

- Up to 60, 000 bottles per hour

- Automation level

- Automatic height adjustment

- Flexibility and modularity

- Modular design, flexible layout

- Operation with incorrect bottle

- Grippers remain open if no cap is detected

- Noise level

- Low-noise operation

- Cap removal precision

- Handles slanted or overtightly screwed caps

- Corrosive resistance (e.g. acids)

- Stainless Steel AISI 304

- Density/particle size

- up to 50 mm cap size

- Cap type

- Metal / Plastic

- Machine footprint

- Modular and flexible design

- Cap diameter

- Up to 50 millimetres

- Decapping heads

- 6 to 25

- Material

- Stainless steel AISI 304

- Layout configuration

- Right-to-left or left-to-right

- Cap removal method

- Rotary

- Cap Diameter Compatibility

- Up to 50 mm

- Decapping Heads

- 6 to 25 heads

- Line Output

- Up to 60, 000 bottles per hour

- Layout Configurations

- Modular with right-to-left or left-to-right design

- Material

- Stainless steel AISI 304

- Noise and Wear Reduction

- Roller-controlled grippers