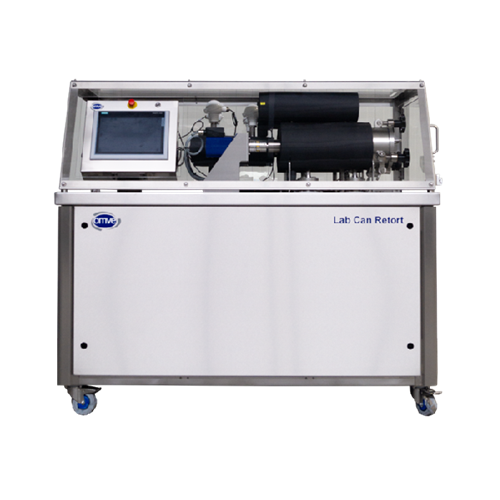

Lab can retort for precise temperature and pressure control

Achieve precision in recipe validation and packaging testing with a laboratory retort that ensures exact control over temperature, pressure, and agitation, essential for developing shelf-stable, low-acid canned foods and beverages.

Controls Temperature, Pressure, and Agitation for Testing

The HT207 Lab Can Retort from OMVE is a precision laboratory system designed for food and beverage developers needing reliable control over heat treatment processes. This equipment stands out by offering precise temperature, pressure, and agitation controls essential for testing and validating new recipes and packaging materials. Equipped with advanced data loggers and intelligent controls, it ensures accurate heat penetration and temperature distribution tests, critical for shelf-stable low-acid canned foods and beverages. Suitable for applications across plant-based, dairy, and nutraceutical industries, the HT207 supports a wide range of end products such as almond milk, craft soda, and canned cocktails. Its compact design and user-friendly interface make it ideal for research and development departments focused on fine-tuning product formulations. The system is built with automation for streamlined operations and can integrate seamlessly into lab environments for efficient product testing. Moreover, it facilitates sustainability efforts by enabling precise energy usage monitoring during testing phases.

Benefits

- Enhances product safety and quality through precise control of heat treatment parameters.

- Accelerates product development cycles with efficient testing and validation of new formulations.

- Reduces material waste by optimizing packaging material assessments.

- Facilitates compliance with industry standards for shelf-stable products.

- Streamlines research processes with integrated data logging for detailed analysis.

- Applications

- Soups, Alcoholic drinks, Sauces, Nutraceuticals, Fats, Still drinks, Oils, Plant-based products, Ice creams, Carbonated drinks, Dairy products

- End products

- Canned cocktails, Béchamel sauce, Protein shakes, Fruit juice, Craft beer, Almond milk, Sparkling water, Minestrone, Pesto sauce, Tomato soup, Craft soda, Oat yogurt, Butter, Coconut oil, Gelato, Vitamin water, Herbal tea, Tofu, Sorbet

- Steps before

- Recipe Validation, Consumer Testing

- Steps after

- Heat Penetration Testing, Temperature Distribution Testing, Packing, Shelf-Stability Assessment

- Input ingredients

- shelf-stable low-acid canned foods, beverages, new packaging materials, food containers

- Output ingredients

- tested recipes, validated consumer products, processed food containers, optimized packaging materials

- Market info

- OMVE is known for manufacturing pilot and small-scale processing equipment for the food and beverage industry, specializing in pasteurization, carbonation, fermentation, and homogenization systems, with a strong reputation for innovation and quality in engineered-to-order solutions.

- Temperature Control

- Precision control

- Pressure Control

- Precision control

- Agitation Control

- Precision control

- Data Logging

- Advanced data loggers

- Automation

- Automated

- Heat Penetration Test Capability

- Yes

- Temperature Distribution Test Capability

- Yes

- Automation level

- Automated / Manual

- Batch vs. continuous operation

- Batch

- Temperature control

- Precision control

- Pressure control

- Precision control

- Agitation control

- Efficient control

- Cleaning method

- CIP / Manual

- Changeover time

- Minimal

- Abrasion resistance

- Yes

- Corrosive resistance (e.g. acids)

- Yes

- Cleanability

- High

- Biological compatibility

- Yes

- Container size and shape

- Variable

- Foaming tendency

- Low to moderate

- Machine footprint

- Compact design

- Control panel type

- Advanced controls with data loggers

- Control panel type

- Advanced data logger and intelligent controls

- Integration possibilities

- Testing capabilities for new packaging materials

- User interface

- User-friendly and automated

- Customization level

- Designed for product development and testing