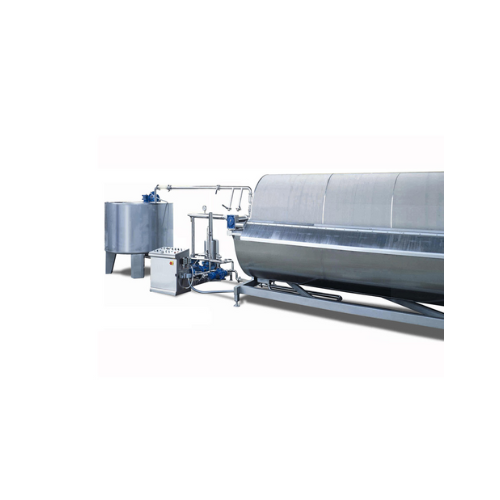

Vacuum rotary filter for liquid filtration

Enhance your production line’s efficiency with precise filtration, ensuring your liquid products are free from impurities. This advanced solution meets the demand for consistent quality and optimizes downstream processes.

Automatically Filters Liquids and Slurries Efficiently

The MQ Vacuum Rotary Filter by INOXPA is designed to address the critical separation needs in industries such as food, dairy, and cosmetics. This equipment excels through its vacuum-based filtration system that enables continuous operation, making it ideal for processing liquids, slurries, and cakes into products like fruit juices, milk powder, and essential oils. The stainless steel AISI 304 construction with a 316 SS filtering screen ensures durability and resistance to corrosion, particularly in demanding environments. It integrates seamlessly into production lines, offering automatic operations with a centralized control panel and automatic blade return after cycle completion. The inclusion of a vacuum pump cooling system with a buffer tank optimizes water use, reducing consumption significantly. Easy inspection and maintenance are facilitated by features such as the manhole for drum access, while the option for stainless steel AISI 316 construction enhances chemical resistance. The equipment is compliant with industry standards for safety and hygiene, and it supports CIP systems for efficient cleaning, minimizing downtime and contamination risks.

Benefits

- Enhances production efficiency with continuous, automated operation.

- Minimizes water use with an integrated vacuum pump cooling system and buffer tank.

- Facilitates fast and thorough cleaning with CIP compatibility, reducing downtime.

- Offers corrosion resistance with optional full stainless steel AISI 316 construction.

- Integrates seamlessly into existing production lines with centralized control and modular design.

- Applications

- Food industry, Cosmetic and pharmaceutical industry, Dairy industry, Bakery industry, Beverage industry

- End products

- Face creams, Wine, Custard, Milk powder, Beer, Shampoo, Yogurt, Fruit juices, Essential oils

- Steps before

- Mixing, Blending, Homogenizing

- Steps after

- Product recovery, Storage, Packaging

- Input ingredients

- liquids, slurries, suspensions

- Output ingredients

- filtered liquid, exhausted cake

- Market info

- INOXPA is known for its expertise in manufacturing stainless steel components and equipment, particularly for the food, dairy, cosmetic, and pharmaceutical industries. They are reputed for high-quality, hygienic, and reliable processing solutions.

- Material

- Stainless steel AISI 304, 316 SS for filtering screen

- Control panel

- Centralized

- Automation

- Automatic blade return

- Filtration system

- Vacuum rotary

- Filtration cycle

- End of cycle automatic operation

- Inspection

- Drum easily inspectable through a manhole

- Vacuum pump cooling system

- Equipped with buffer tank

- Water consumption reduction

- Buffer tank equipped

- Drum washing system

- Automatic

- Discharge method

- Conveyor for exhausted cake

- Working Mechanism

- Vacuum rotary filtration

- Automation Level

- Automatic blade return, PLC-controlled

- Cleaning Method

- Automatic drum washing system

- Batch vs. Continuous Operation

- Batch

- Filtration Cycle

- Automatic cycle

- Energy Efficiency

- Reduced water consumption with buffer tank

- Material Handling

- Discharge of exhausted cake by conveyor

- Filter Maintenance

- Easily inspectable drum

- Cleanability

- Yes

- Corrosive resistance (e.g. acids)

- Stainless Steel AISI 316

- Machine footprint

- Compact

- Material

- Stainless steel AISI 304

- Filtering screen material

- Stainless steel 316

- Filter type

- Vacuum rotary

- Control panel type

- Centralized

- Drum inspection

- Manhole access

- Filtration tank

- Included

- Vacuum pump cooling system

- Buffer tank equipped

- Discharge method

- Conveyor

- Automatic drum washing

- Available

- Exhaust cake discharge

- Screw conveyor

- Control panel type

- Centralized control panel

- Blade return mechanism

- Automatic blade return

- Discharge method

- Discharge of exhausted cake by conveyor

- Drum inspection

- Easily inspectable through a manhole

- Material

- Made in stainless steel AISI 304/316

- Vacuum pump material

- Stainless steel AISI 316

- Cooling system

- Vacuum pump cooling with buffer tank

- Automatic cleaning

- Automatic drum washing system

- Filtered liquid manifold

- Separated from air manifold

- Options for residual liquid filtration

- Available