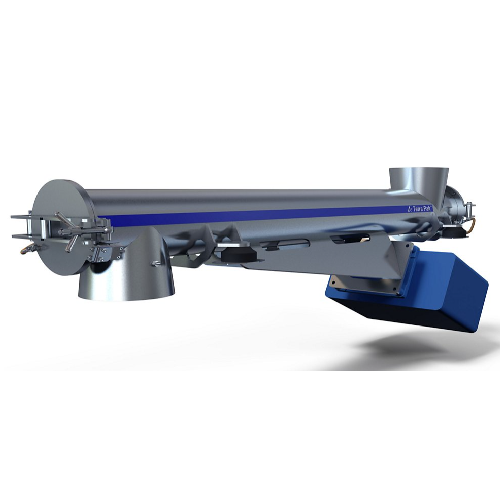

Vibrating conveyor for short-distance powder transport

Achieve precise and hygienic powder conveying and dosing with this high-frequency vibrating conveyor, designed to maintain optimal product quality and eliminate product retention in your processing line.

Conveys and Doses Food Powders Accurately

The Tetra Pak Vibrating Conveyor EV provides a tailored solution for food manufacturers seeking precise powder conveying and dosing. Utilizing high-frequency vibrations, this tubular conveyor eliminates product retention, ensuring gentle handling without direct mechanical contact. Ideal for food powder applications such as infant formula and protein powders, it integrates seamlessly into various production lines with options for unbalanced or electromagnetic motors, catering to both basic and high-capacity needs. Constructed from durable stainless steel, it offers an easy-to-clean design with double-door access for simplified maintenance. Its safety sensor and automatic shut-off enhance operational security, making it an efficient choice for continuous, high-accuracy processing.

Benefits

- Enhances operational accuracy with precise dosing capabilities.

- Minimizes contamination risk with hygienic stainless steel construction.

- Supports efficient, continuous production with zero product retention.

- Reduces maintenance downtime with easy-access design.

- Ensures operator safety with automatic shut-off feature when accessed.

- Applications

- Food powder products, Nectar, Cheese, Plant-based products, Milk powder, Plant-based powder, Ice cream, Infant formula powder, Powder handling, Whey, Juice, Dairy

- End products

- Malted milk powder, Cocoa powder, Plant protein powder, Baking powder, Infant formula, Non-dairy milk powder, Soup mix powder, Protein powder, Nutritional supplement powder, Cheese powder, Powdered juice

- Steps before

- Drying, Grinding

- Steps after

- Packing, Sterilization

- Input ingredients

- powder, food powder products, non-flowable powders

- Output ingredients

- conveyed powder, dosed powder

- Market info

- Tetra Pak is renowned for providing innovative packaging solutions, specializing in carton packaging for the food and beverage industry. It is esteemed for high-quality, sustainable, and efficient processing and packaging equipment on a global scale.

- Conveying type

- Vibrating conveyor

- Material type

- Powder

- Conveying distance

- Short-distance

- Motor type

- Unbalanced motor / Electromagnetic vibrator

- Hygienic design

- Stainless steel

- Cleaning method

- Easy clean, no product retention

- Access type

- Double-door access from both ends

- Product contact

- No mechanical parts in contact

- Capacity

- High capacity

- Accuracy

- High accuracy

- Working mechanism

- High-frequency jolts of small amplitude

- Automation level

- Automatic control via frequency and amplitude

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Easy access and no product retention

- Hygienic design

- No mechanical parts contact product

- Safety feature

- Safety sensor with automatic stop

- Material handling

- No product retention

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Suitable for

- Food powders

- Conveyor Type

- Tubular

- Material

- Stainless Steel

- Access

- Double-door access

- Footprint

- Compact

- Motor Type

- Unbalanced or Electromagnetic

- Discharge Method

- Vibration

- Cleaning Method

- Easy Cleaning

- Motor Type

- Unbalanced / Electromagnetic

- Frequency Control

- Adjustable

- Amplitude Control

- Adjustable

- Door Access

- Double-door