Aseptic filtration system for juice production

Ensure the microbiological quality and turbidity of juices and concentrates by eliminating Alicyclobacillus spores while offering dual functionality as a juice pasteurizer.

Filters and Pasteurizes Juice and Beverage Concentrates

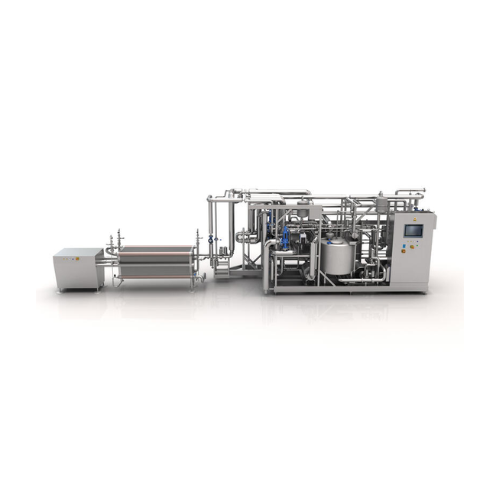

The MONA Aseptic Filtration System from Bucher Unipektin is a compact device designed to enhance the microbiological quality of juice and concentrate production. Specializing in the elimination of Alicyclobacillus spores, the system optimizes turbidity through a dual-function design that allows for both filtration and standard pasteurization.

The unit processes both concentrate and NFC juices, accommodating aseptic filling systems for a versatile addition to your production line. Utilizing a two-section plate heat exchanger (PHE), it efficiently pre-heats and filters the concentrate, ensuring a final aseptic product free of impurities and microorganisms.

With a processing capacity ranging from 8 to 15 tons per hour, the MONA system operates under a continuous and automatic cycle, ensuring seamless integration into existing setups. It supports steam pressure up to 5 bar and consumption between 300 and 550 kg/h, with available material options of AISI 304 or AISI 316L for improved corrosion resistance.

For automation, the system employs a Simatic S-7-1500 control, offering reliable process monitoring and data archiving. Compliance with hygienic standards is assured, with integrated sterilization and cleaning processes allowing for hassle-free maintenance. Custom engineering support is available, ensuring the system meets specific production needs.

Benefits

- Enhances product quality by eliminating microorganisms, including Alicyclobacillus spores.

- Increases process efficiency with dual-function capability for both juice filtration and pasteurization.

- Reduces operating costs through optimal filter use and steam consumption management.

- Ensures product safety and consistency with comprehensive process monitoring and data archiving.

- Facilitates easy system integration with flexible material options and aseptic filling compatibility.

- Applications

- Juices, Nfc juices, Beverage concentrates

- End products

- Nfc aseptic apple juice, Aseptic berry juice, Aseptic citrus concentrate, Nfc aseptic orange juice, Aseptic apple concentrate, Aseptic tropical fruit concentrate, Nfc aseptic berry juice, Aseptic apple juice, Nfc aseptic citrus juice, Aseptic orange juice

- Steps before

- Heating, Pre-heating, Viscosity reduction

- Steps after

- Cooling, Aseptic filling, Regeneration of heat

- Input ingredients

- juice concentrate, NFC juice, water

- Output ingredients

- aseptic juice concentrate, sterile juice, reduced ACB spores, improved microbiological quality, improved turbidity

- Market info

- Bucher Unipektin is known for producing advanced equipment and systems for the food and beverage industry, specializing in juice processing and filtration technologies with a reputation for innovative solutions and reliable, high-quality products.

- Capacity

- 8-15 t/h

- Weight

- 6.3-11.8 t

- Dimensions

- 10800x2530x2510 mm

- Control System

- Simatic S-7-1500

- Filtration Surface

- 55 m² / 62 m² / 76 m²

- Steam Pressure

- 5 bar

- Steam Consumption

- 300 kg/h / 380 kg/h / 550 kg/h

- Material

- AISI 304 / AISI 316L optionally

- Filtered Concentrate

- 250 t / 300 t / 450 t

- Working Mechanism

- Dual-function

- Integrated Steps

- Pre-filtration and sterile filtration

- CIP/SIP

- Closed circuit with water sterilization and thermal disinfection

- Batch vs. Continuous Operation

- Batch operation

- Automation Level

- Simatic S-7-1500 controlled

- Control System

- Two-stage

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Microbiological Quality

- Improves quality

- Machine footprint

- 10800x2530x2510mm

- Weight

- 6.3-11.8t

- Filtration surface

- 55m²/62m²/76m²

- Material

- AISI 304/AISI 316L

- Control panel type

- Simatic S-7-1500

- Integration possibilities

- Aseptic filling system connection