Membrane mash filter for brewing

Optimize your brewing process with advanced membrane filtration, ensuring maximum yield and enhanced wort quality, while accommodating a variety of recipes and batch sizes with minimal space requirements.

Extracts High-Quality Wort Efficiently

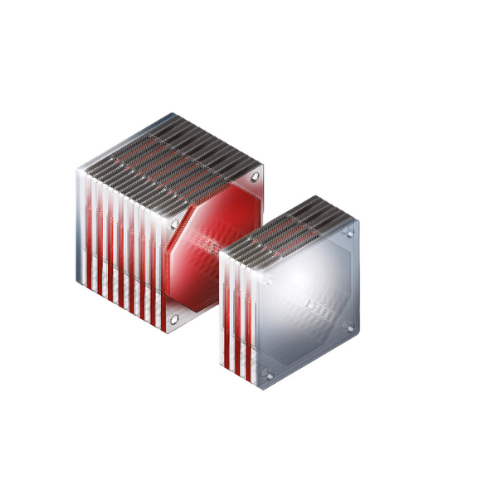

The Butterfly Membrane Mash Filter from Ziemann Holvrieka revolutionizes mash filtration with its mixed plate package design, alternating chamber and membrane plates for exceptional wort quality and extraction. This system serves a variety of applications including craft beers, hard seltzer, and plant-based drinks, accommodating diverse end-products like lagers and fermented beverages. Operating on a fully automatic basis, the Butterfly system efficiently integrates into your brewhouse, requiring minimal control system adjustments. Designed for continuous operation, it significantly reduces water consumption while ensuring optimal extraction with high yield efficiency. The system, constructed with durable thermoplastic elastomer membranes, guarantees a service life beyond 12,000 brews. It also features a patented automatic cloth cleaning system for hassle-free maintenance. This compact, space-saving solution is ideal for breweries processing alternative cereals or focusing on high extract content, providing versatility in recipe design and production processes.

Benefits

- Maximizes wort extraction while minimizing water usage, enhancing resource efficiency.

- Adapts to diverse batch sizes and cereal types, offering versatile production capabilities.

- Seamlessly integrates with existing brewhouse setups, simplifying upgrades.

- Ensures prolonged operational life, reducing maintenance frequency and costs.

- Optimizes brewery space utilization with its compact design.

- Applications

- Chemicals, Distilling, Beyond-beer beverages, Hard seltzer, Beer, Juice, Edible oil, New food, Dairy

- End products

- Distilled spirits, Lager, Non-alcoholic beer, Stout, Craft beers, Flavored spirits, Malt extract, Fermented beverages, Vodka, Fruit juice concentrates, Olive oil, Specialty chemicals, Whiskey, Organic acids, Wheat beer, Plant-based milk, Edible oils - sunflower oil, Ipas, Flavored dairy drinks, Gin

- Steps before

- Mashing, Mixing, Heating

- Steps after

- Boiling, Fermentation, Cooling, Clarification

- Input ingredients

- mash, spent grains, alternative cereals, starch sources, wort types with high extract content

- Output ingredients

- wort, high extract recovery, minimal sparging water usage, spent grains cake

- Market info

- Ziemann Holvrieka is known for its expertise in providing industrial engineered-to-order equipment for breweries. They design and manufacture advanced brewing systems and solutions, earning a strong reputation for quality and innovation in the brewing industry.

- Filtration system

- Membrane mash filter

- Plate design

- Double Plate Design

- Cycle life

- 12, 000 brews

- Automation

- Fully automatic cloth cleaning

- Integration

- Seamless Integration

- Space requirement

- Compact design

- Wort extraction

- Maximum Wort Extraction

- Pressing medium

- Water

- Working mechanism

- Membrane technology with mixed plate design

- Automation level

- Fully automatic with PLC/SCADA

- Batch vs. continuous operation

- Batch

- CIP/SIP

- Fully Automatic Cloth Cleaning

- Integration capability

- Seamless Integration as Stand-alone

- Space requirement

- Compact design

- Abrasion resistance

- High

- Biological compatibility

- Food grade

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- Resistant

- Density/particle size

- Uniform particle handling

- Flexibility

- Handles high extract content

- Compact footprint

- Space-saving design

- Control panel type

- Signal exchange integration

- Discharge method

- Both directions pressing

- Plate design

- Mixed chamber and membrane plates

- Membrane Material

- Thermoplastic elastomer (TPE)

- Cleaning system

- Fully automatic cloth cleaning

- Brews service life

- 12, 000 brews

- Control panel type

- Signal exchange in control system

- Compact footprint

- Yes

- Integration possibilities

- Seamless integration into existing brewhouses