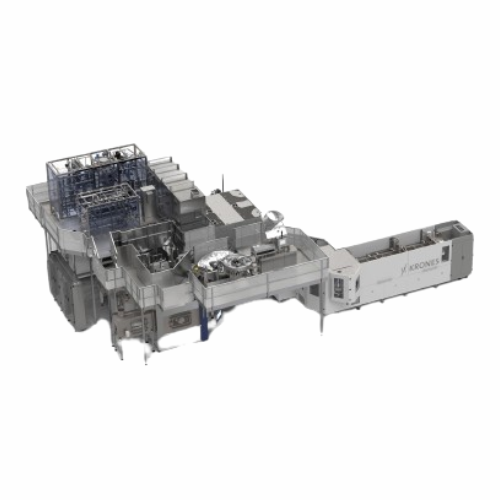

Aseptic filling system for Pet containers

Ensure your beverage products maintain sterility and longevity with a high-speed, aseptic filling system, streamlining preform sterilization and bottling for a seamless production process.

Sterilizes, Moulds, Fills, and Caps PET Containers

The Contipure AseptBloc from Krones seamlessly integrates preform sterilization, blow molding, filling, and capping in a single aseptic solution for PET containers. Featuring a unique single-medium sterilization using gaseous hydrogen peroxide, it ensures complete sterility inside and out. Ideal for high-demand beverage sectors, its production line accommodates milk, juices, and plant-based drinks with a throughput of up to 72,000 containers per hour. Its fully automatic operation allows for non-stop production over 168 hours, with quick changeovers and minimal manual intervention. The aseptic system meets FDA certification standards, providing microbiological safety without water consumption, preventing microbial growth altogether. Designed with energy-efficient features, it uses infrared ovens with parabolic mirrors and servo-controlled components to optimize preform handling. Krones offers engineering support for customized configurations, ensuring the system seamlessly integrates into any beverage production line.

Benefits

- Ensures product safety with complete aseptic processing, extending shelf life without preservatives.

- Increases production efficiency with up to 72,000 containers per hour and continuous 168-hour operation.

- Minimizes manual intervention, reducing labor costs and risk of contamination.

- Reduces energy consumption through optimized preform handling and infrared heating.

- Complies with FDA standards, safeguarding microbiological integrity and product quality.

- Applications

- Water, Milk and milk-based drinks, Pet containers, Spirits, Plant-based milk alternatives, Juice, Aseptic filling, Soft drinks

- End products

- Bottled water, Still water, Uht milk, Long-life milk, Non-carbonated soft drinks, Orange juice, Mango juice, Ready-to-drink tea, Almond milk, Oat milk, Sparkling water, Rice milk, Fruit spirits, Vodka, Flavored milk drinks, Apple juice, Gin, Soy milk, Coconut water, Lactose-free milk, Carbonated soft drinks

- Steps before

- Preform Manufacturing, Preform Heating, Preform Drying, Preform Cleaning

- Steps after

- Sterilization, Capping, Filling, Packing

- Input ingredients

- preforms, caps, gaseous hydrogen peroxide (H2O2)

- Output ingredients

- aseptic PET containers, filled and capped bottles

- Market info

- Krones is renowned for its expertise in manufacturing beverage and liquid food processing and packaging equipment, offering comprehensive solutions that include filling, packaging technology, and processing systems, and is reputed for innovation and quality in the industry.

- Output

- Up to 72, 000 containers per hour

- Sterilisation Medium

- Gaseous Hydrogen Peroxide (H2O2)

- Preform Range

- Round, Square and Rectangular PET Containers

- Container Type

- Standard and Lightweight PET

- Cleaning Time

- 90 minutes to 2.5 hours

- Changeover Time

- Automatic up to defined output

- Non-stop Production Duration

- 168 hours

- Integrated Steps

- Preform sterilisation, blow moulding, filling, capping

- Sterilisation Medium

- Gaseous hydrogen peroxide (H2O2)

- Output Capacity

- Up to 72, 000 containers per hour

- Product Compatibility

- Aseptic filling of PET containers

- Automation Level

- Servo-controlled automation

- Cleaning and Sterilisation

- Automatic, gaseous H2O2

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container type

- PET

- Container size

- Round, square, rectangular

- Material compatibility

- Standard and lightweight PET

- Integration possibilities

- Block-synchronised systems

- Control panel type

- Servo-controlled

- Change-over flexibility

- Fully-automatic change-over

- Modular design

- Variants adjustable depending on installation

- Sterilisation medium

- Gaseous hydrogen peroxide (H2O2)