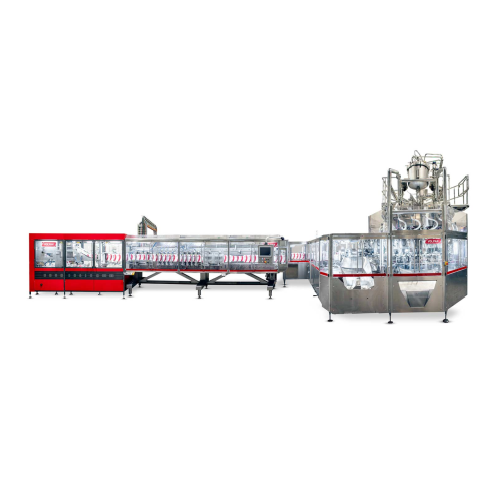

Continuous stand-up pouching solution for up to 1000ml

Maximize efficiency in high-speed production lines with precise stand-up pouch solutions, designed to handle diverse liquid and solid products seamlessly.

Pouches Liquid and Solid Products Efficiently

The SC+ 180 from Volpak is a high-speed horizontal stand-up pouch machine designed for a diverse range of industries, including Beverages, Food, Personal Care, Dairy, and Chemicals. It enables continuous operations with speeds reaching up to 400 pouches per minute, efficiently catering to both liquid and solid products. The machine’s standout capability lies in its flexibility to handle pouch sizes up to 1000ml, crucial for products like juices, shampoos, and soups. Integrated with advanced PLC controls, it ensures seamless line automation and remote monitoring, enhancing production uptime. The SC+ 180’s modular design allows for customization to suit specific product requirements, and its construction supports hygienic operations, critical for food and dairy industries. Furthermore, it supports efficient energy use through optimized motor control, aligning with sustainability targets.

Benefits

- Increases production efficiency with speeds up to 400 pouches per minute.

- Adapts to diverse product demands with flexibility for liquids and solids up to 1000ml.

- Enhances operational uptime through integrated PLC controls and remote monitoring.

- Meets hygienic standards for food and dairy production.

- Supports sustainable operations with optimized energy consumption.

- Applications

- Biscuits, Sauces, Sealants, Snacks, Dairy products, Fats, Oils, Spirits, Cosmetics, Stock cubes, Home care products, Soft drinks, Processed vegetables, Hair care products, Liquid soaps, Chemicals, Soups, Wine, Fragrances, Processed fruits, Chocolates, Condiments, Bars, Candies, Frozen foods, Juices, Sunscreen products, Spreads, Pet care products, Pet foods, Food products, Baby food, Beverages, Baked goods, Personal care products, Ready-to-drink beverages, Coatings, Gums, Cereals, Dishwashing detergents, Crackers, Lubricants, Skin care products, Laundry care products

- End products

- Hair conditioner, Skin serum, Olive tapenade, Baby lotion, Pancake syrup, Protein shakes, Red wine, Beef stew cubes, Sports drinks, Engine oil, Potato chips, Baby shampoo, Antibacterial hand soap, Mango puree, Tomato paste, Pomegranate tea, Bbq sauce, Deodorant spray, Mushroom soup, Granola bars, Sour cream, Walnut oil, Dry dog food, Orange juice, Vanilla extract, Vanilla body lotion, Almond milk, Energy drinks, Herbal tinctures, Chewy candies, Honey roasted peanuts, Pumpkin puree, Salsa, Chocolate milk, Aloe vera gel, Lavender fabric softener, Hazelnut spread, Fruit juice concentrates, Face moisturizer, Liquid detergent, Cornflakes, Orange marmalade, Fireplace sealant, Sunscreen lotion, Banana chips, Whiskey, Rosewater toner, Ginger ale, Soy milk, Peach iced tea, Peppermint gum, Cat food, Coconut oil, Car polish, Blueberry jam, Chicken noodle soup, Diet cola, Dishwashing liquid, Strawberry yogurt, Iced tea, Maple syrup, Lavender bath salts, Blueberry muffins

- Steps before

- Mixing, Emulsification, Formulation, Heating, Homogenization

- Steps after

- Filling, Sealing, Capping, Labeling, Packing

- Input ingredients

- Soft Drinks, RTDs, Juice, Wine, Spirits, Other Beverage, Other Home Care, Dishwashing, Laundry Care, Cosmetics, Fragrances, Hair Care, Skin, Sun Care, Liquid Soaps, Baby Food, Baked Goods, Biscuits, Crackers, Candies, Gums, Cereals, Chocolate, Bars, Frozen Food, Oils, Fats, Other Food, Sauces, Condiments, Snacks, Soup, Stock Cubes, Spreads, Processed Fruits, Vegetables, Other Dairy, Pet Food, Other Pet Care, Coatings, Sealants, Lubricants, Other Chemicals

- Output ingredients

- stand-up pouches up to 1000ml

- Market info

- Volpak (Coesia Group) is known for its expertise in designing and manufacturing horizontal form-fill-seal machines, specializing in flexible packaging solutions for the food, beverage, and personal care industries, with a reputation for innovation and efficiency.

- Speed

- Up to 400 ppm

- Capacity

- Up to 1000 ml

- Technology

- Horizontal Stand-up Pouching

- Operation

- Continuous high speed

- Working mechanism

- Horizontal Stand-up Pouching

- Batch vs. continuous operation

- Continuous

- Maximum pouch volume

- up to 1000 ml

- Speed

- up to 400 ppm

- Automation level

- Automated

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- N/A

- Discharge method

- Continuous

- Pouch size capacity

- Up to 1000ml

- Control panel type

- HMI interface

- Integration possibilities

- Seamless integration with existing systems

- Customization for pouch sizes

- Up to 1000ml

- Production Speed Adjustment

- Variable, up to 400ppm